22

34-55 08/14

10 BOILER

CONTROL

INTERFACE

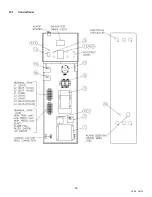

A terminal strip for the remote connection is located behind the hinged control panel at the top of the cabinet and is

accessed by removing the bottom cover and then removing the screws at the top of the hinged cover.

10.1 If BMS/BAS provides remote on/off control directly to each boiler but allows boiler to control modulation on

its own:

•

Remove the jumper connecting terminals R1 and R2.

•

Connect the BMS output leads for the enable/disable function to terminals R1 and R2.

•

Leave all other wires in their initial positions.

10.2 If BMS/BAS provides MODULATION control through a 4 to 20 milliamp directly to each boiler:

•

Remove the jumper connecting terminals R1 and R2.

•

Connect the BMS output leads for the enable/disable function to terminals R1 and R2 (no polarity).

•

Remove blue wire from terminal T1 and cap the end with a wire nut. Secure the loose wire.

•

Connect the BMS variable signal output leads to terminals T1 and T2 (T1 is positive, T2 is negative).

•

On the TempTrac Control, move parameter St1 up to its maximum setting of 230°F. This setting effectively

takes the TempTrac out of the way and allows complete control by the BMS system.

10.3 BAS connection over network with MODBUS RTU protocol (requires option ALMMB)

•

An optional serial connection cable (part no. 106624) enables the TempTrac to communicate via Modbus

RTU to a Building Automation System or to the OnTrac multiple boiler control. Connections are made using

shielded, twisted pair wiring in a daisy chain arrangement.

10.4 Making BMS/BAS remote connections for analog and binary (on/off) signals

A terminal strip for the remote connection is located behind the hinged control panel at the top of the cabinet and is

accessed by removing the bottom cover and then removing the screws at the top of the hinged cover.

IMPORTANT:

Do not use single strand bell wire for remote field connections to terminals R1-R2 and C1-C2. Use

only multi-strand copper wire. See table below for wire length and gauge:

WARNING: Turn off all electrical service to the appliance when accessing the remote connections located

inside the control cabinet. These terminals are High Voltage. If the electrical service is not turned off and

these terminals are touched, a dangerous shock causing personal injury or death could occur. Close and

fasten the control cabinet cover before restoring electrical service to the appliance

The Following Describes The Functions Of Each Of These Terminals And The Factory-Installed Options

Required To Activate The Terminals:

Note

: Terminals

A1-A2

and

P1-P2

are functional only when the boiler is equipped with the factory installed options

required to activate the terminals. Terminals

R1-R2

,

C1-C2

and

T1-T2

are standard pre-wired functions on all

models.

R1-R2:

Used to activate /de-activate boiler from remote master control.

Terminals are wired to a relay in a remote Boiler Management or Energy Management System. When relay

closes, circuit from R1 to R2 is completed and appliance controls are enabled. Appliance ships from factory with

jumper between terminals Remove jumper when connecting to a remote controller.

Wire Gauge

18 GA

16GA

14 GA

12 GA

Maximum Length

30 FT

50 FT

75 FT

100 FT