26

34-55 08/14

12 INITIAL

STARTUP

12.1 Initial Startup Requirements

Installation should be complete prior to performing initial startup; and the startup must be complete prior to placing

the boiler into service. Starting the boiler without proper piping, combustion air, venting or electrical systems can be

dangerous and may void the product warranty. The following startup instructions should be followed precisely in

order to achieve safe and efficient operation to assure trouble-free service life.

WARNING: Start-up must be performed by a qualified technician. The Start-up Forms is included with each

product and must be furnished to the manufacture to register the warranty. Copies are available at

www.riversidehydronics.com. Failure to comply can cause property damage, personal injury and exposure

to hazardous materials or death.

WARNING: Turn off all power to the boiler when servicing or accessing the blower drive. The blower drive

still has power when appliance switch is off. Failure to turn off all power to the boiler can cause personal

injury, property damage or death.

12.1 Tools and Instrumentation Required

•

Stack Temperature Gauge

•

Stack Draft Gauge

•

Electronic Combustion Analyzer

•

Manometer for checking gas pressure (2 minimum)

•

AC/DC Multi-meter (with 20,000 OHM/Volt rating)

•

Amp Meter

•

Normal Hand Tools

12.2 Resources

•

Product Installation & Maintenance Manuals

•

Start-up Report with instructions

•

Local, State, & Federal Codes

•

Toll Free 24-Hour Technical Support: 1-800-433-5654

12.3 On Site Considerations

•

Electrical Supply in accordance with Nameplate Rating

•

Uncontaminated Combustion Air

•

Adequate Fuel Supply

•

Treated Water Supply (Boilers)

•

Consistent Draft

12.4 Startup Procedure

1.

Carefully study the burner start-up information included in this manual.

2.

Fill system tank with water. Some water appliances may be equipped with an optional air vent. If venting

through the safety valve when filling the appliance, insure gags or fixtures are removed from the safety valve

prior to start-up. Open the safety valve to allow air in the tank to escape.

3.

Be sure all connections into the tank are tight, as leaks at tank fittings will damage the insulation.

4.

CAUTION:

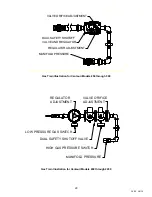

Conduct the following gas train leakage test before start-up, at annual intervals and prior to

investigating the cause of any reported occurrences of delayed ignition.

a. Using an appropriate bubble detection solution, thoroughly coat all gas train pipe connections. If any

bubbles are detected, the leaking connection must be tightened, recoated, and rechecked to assure

stoppage of the leak.

b. Attach a manometer to measure the gas pressure at the manual gas shutoff valve located just upstream

of the gas train. Adjust gas train inlet pressure to the specified value (e.g. 14" W.C.), and tightly close the

gas train manual shutoff valve closest to the burner.