36

34-55 08/14

15 PERIODIC MAINTENANCE

Listed below are items that must be checked to ensure safe reliable operations. Maintenance must be performed

by a qualified service or maintenance provider. To ensure proper maintenance, the following instructions should

be posted near the appliance and maintained in legible condition. Verify proper operation after servicing.

WARNING: When servicing the controls, use exact, Factory authorized, replacement parts and label all

wires prior to disconnection. Verify proper operation after servicing. Incorrect parts substitution and

wiring errors can cause damage, improper operation, fire, carbon monoxide and other unexpected and

unsafe conditions that could result in fire, injury or death.

1. Examine the appliance and venting system at least once a year. Check more often in first year to determine

inspection interval.

a. Check all joints and pipe connections for tightness, corrosion or deterioration.

b. Check the electronic-ignition system for quick ignition and a proper flame signal.

c. Check all safety controls including thermostats for proper operation.

d. Check safety shut-off valves for operation and tightness.

e. Have the entire system, including, but not limited to, the burner, heat exchanger and venting system,

periodically inspected by a qualified service agency.

2. Exposure to Dusty or Dirty Combustion Air: An appliance installed in a dust or dirt contaminated atmosphere

will require replacement of the filter on a 3 to 6 month schedule or more often, based on severity of

contamination. Contaminants can be drawn in with the combustion air. Inadequate combustion air or non-

combustible particulate matter such as dust, dirt, dryer lint, concrete dust, dry wall dust or the like can block

burner ports and cause unsafe operation and a non-warrantable failure. Do not remove filter without a

suitable replacement. To inspect and clean the burner, a qualified serviceman or installer should use the

procedures described in item 5 & 6 below.

3. Any sign of soot on the heat exchanger or in the flue indicates the need for a combustion inspection. Properly

installed and adjusted units seldom need heat exchanger cleaning. If soot has formed, the most common

causes are restricted combustion air or excessive gas. A blocked heat exchanger can cause unsafe

operation and will reduce efficiency. To inspect and clean the heat exchanger, a qualified service agent or

installer should use the procedures described in item 5 & 6 below.

4. All gaskets on disassembled components must be replaced on reassembly with exact, Factory Authorized,

replacement parts only. Gasket kits are available from your Riverside Hydronics

®

Representative or by

contacting Riverside Hydronics

®

, LLC.

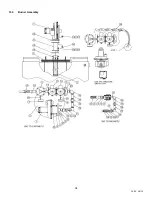

5. Burner and/or Heat Exchanger Inspection and Cleaning Procedure:

a. Turn off main power to unit.

b. Turn off gas supply.

c. Write notes and/or take pictures during this process to aid in correct reassembly.

d. Remove the hot surface igniter, (HSI) from the burner. Be very careful not to bump the igniter element

due to the fragility of the igniter.

e. Remove the nuts that secure the burner top plate to the burner flange and lift the burner top plate up until

it is completely extracted from the burner.

f. Inspect top plate refractory for damage. The refractory should provide a tight seal against the top edge of

the burner deck. The silicone foam gasket located on the top plate flange should also be checked for

damage or excessive compression set.

g. With the burner top plate removed, inspect the deck surface of the burner for lent or other blockage

carried in the fuel air stream. If blockage has accumulated, use brush to loosen debris and use a vacuum

to remove from the burner cavities. Do not brush or scrub the metal fiber burner surface as this can cause

permanent damage to the burner material.

h. Replace any damaged components and reassemble in reverse order. (4-5 ft/lbs).

i. Cycle unit and test to verify all safety and operating controls are properly functioning and the burner top

plate flange is free of leaks.