10

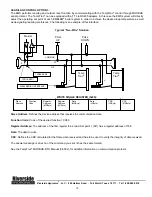

LEAD/LAG CONTROL OPTION 3:

The EMS performs lead-lag and outdoor reset function by communicating with the TempTrac

®

control through MODBUS

serial protocol. The TempTrac

®

can be equipped with a TTL to RS485 adapter. In this case the EMS system will directly

adjust the operating set point of each EMBLEM

®

boiler system in order to achieve the desired loop temperature as well

as designating lead-lag preference. The following is an example of this interface:

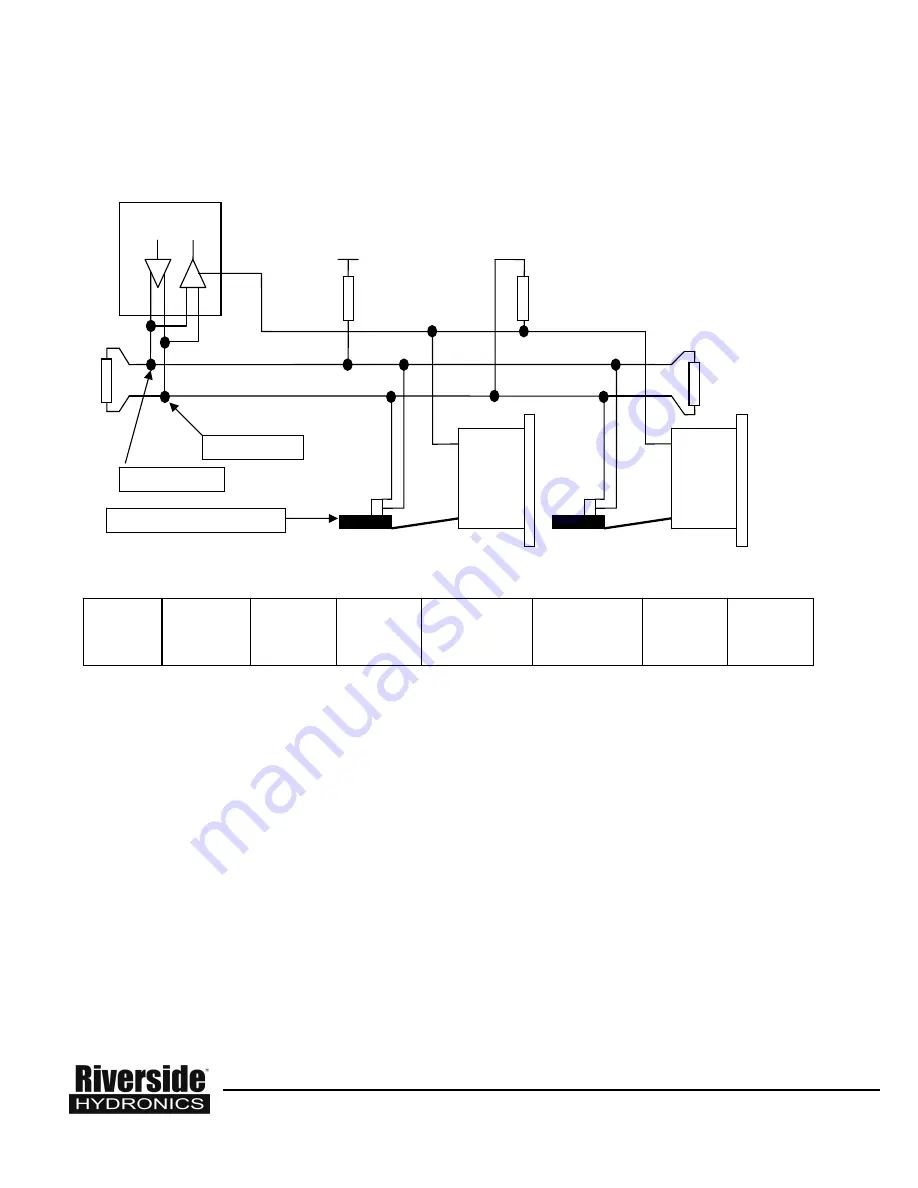

Typical “Two-Wire” Solution

WRITE SINGLE REGISTER (0x06):

Slave Address

: Defines the device address that receives the communication data.

Function Code

: Code of the desired function = 0X06

Register Address

: The address of the first register to be read. Set point 1 (St1) has a register address of 768

Data:

The data to write

CRC

: Defines the CRC calculated for the frame data received and has to be used to verify the integrity of data received.

The answer message is an echo of the command you sent (it has the same format).

See the TempTrac

®

MODBUS-RTU Manual (34-502), for addition information on communication protocol.

Riverside Hydronics

®

, LLC - 990 Haltom Road - Fort Worth, Texas 76117 - Tel 1-800-990-5918

Slave

Address

Function

Code

Register

Address

(MSByte)

Register

Address

(LSByte)

Data

(MSByte)

Data

(LSByte)

CRC

(LSByte)

CRC

(MSByte)

Master

Temp

Trac

®

Temp

Trac

®

D0

D1

COMMON

L

L

-

+

TXD0&RXD0

TXD1& RXD1

-

+

PULL

DOWN

PULL

UP

XJ485 SERIAL INTERFACE