EMBLEM

®

OVERVIEW

- The EMBLEM

®

is a boiler heating system that interconnects a condensing boiler

with a non-condensing boiler and uses a control algorithm to fire each or both boilers as necessary to meet

the building heat requirements while providing maximum efficiency throughout the heating season.

During periods of low to medium building heat demand, whether seasonal or occupancy driven or both,

significant fuel savings can be realized by reducing the boiler loop temperature. A condensing boiler offers

the greatest value to building owners when loop temperatures are low enough (< 130°F) to allow the water

vapor in flue products to condense inside the boiler where the latent energy (heat) of condensation is

captured. The condensing boiler in the EMBLEM

®

system is sized to meet the output requirement during low

to medium heat demand. Because it captures the latent heat released during condensation, thermal

efficiency ranges from 93% to 99% depending upon return water temperature and firing rate. A modular

arrangement of non-condensing boilers, even with modulation, is unable to capture this heat and, as a

result, is less efficient.

During periods of higher building heat demand, loop temperatures are normally elevated and are too high to

allow condensing of flue gases. As a result, firing additional condensing boilers with loop temperatures

greater than 130°F offers little efficiency advantage compared to non-condensing boilers. When heat

demand and loop temperatures are high, the EMBLEM

®

system engages a non-condensing boiler to

supplement heat output. Although non-condensing, the secondary boiler in the EMBLEM

®

system still

operates at relatively high efficiency of 85%. The combined output of each boiler in the EMBLEM

®

system

meets building demand during the coldest days of the heating season.

Over the heating season, the average output of a boiler system is approximately 35% of its total heating

capacity. Such oversizing is unavoidable because of the few unusually cold days when maximum heating

system output is essential to building comfort. EMBLEM

®

intelligently combines boilers of different

efficiencies and fires those boilers when appropriate during the heating season to meet all heat

requirements and maximize fuel savings for the building owner.

Riverside Hydronics

®

, LLC - 990 Haltom Road - Fort Worth, Texas 76117 - Tel 1-800-990-5918

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause property

damage, personal injury, exposure to hazardous materials or loss of life. Refer to and follow the information

contained in this manual, the PRIMERA

®

I&M, the EPV

®

I&M, all provided documents labels and warnings.

Installation and service must be performed by a qualified installer, service agency or the gas supplier, who

must read and follow all supplied instructions before installing, servicing or removing these appliances.

CONTENTS

TOPIC

PAGE

TOPIC

PAGE

General Safety Warnings and Codes

1 & 2

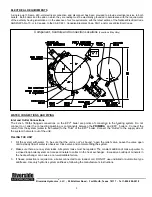

Heating Boiler System Piping

5

EMBLEM

®

Overview

2

Piping Illustration

6

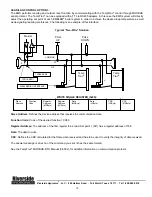

Electrical and Water Connections

3

Water Considerations

7

Operation and General Information

4

Lead/Lag Systems

8-10

General Information

4