3

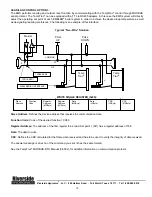

ELECTRICAL REQUIREMENTS

A single point 30-amp, 240-volt electrical connection and disconnect has been provided to provide electrical service to both

boilers. Both boilers and the skid on which they are resting must be electrically grounded in accordance with the requirements

of the authority having jurisdiction or in the absence of such requirements, with the latest edition of the National Electrical Code

ANSI/NFPA No. 70, or in Canada, to the CAE C22.1, Canadian Electrical Code, Part 1 and/or Local Electrical Codes.

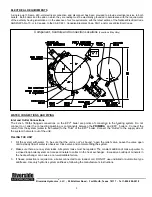

WATER CONNECTIONS AND PIPING

Inlet and Outlet Connections

The 4-inch, 150lbs flanged connections on the EPV

®

boiler are points of connection to the heating system. Do not

connect to or alter the connecting plumbing or components between the

PRIMERA

®

and EPV

®

boilers. Connect the

return from the system (water to be heated) to the “Inlet” of the EPV

®

boiler. Connect the “Outlet” to the supply side of

the system (hot water out of the unit).

FILLING THE UNIT

1. Fill the system with water. To be sure that the unit is not “air bound,” open the relief valve. Leave the valve open

until a steady flow of water is observed. Close valve and complete filling the system.

2. Make sure there are no system leaks. All system leaks must be repaired. The constant addition of make-up water to

a closed loop boiler system can cause minerals to collect in the heat exchanger. Excessive buildup of minerals in

the heat exchanger can cause a non-warrantable failure.

3. If freeze protection is required on a boiler connected to an indirect coil, DO NOT use undiluted or automotive type

antifreeze. Use only hydronic system antifreeze, following the manufacturer’s instructions.

Riverside Hydronics

®

, LLC - 990 Haltom Road - Fort Worth, Texas 76117 - Tel 1-800-990-5918

Component, Controls and Connection Locations

(Locations May Vary)