9

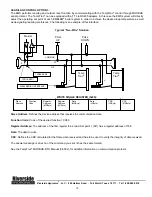

A variation on this example might be to shift back the set point on the weekend in order to reduce loop

temperature and save energy beginning 5:00PM Friday. In this case Sb# would be -20 for the lead boiler -25 for

the lag boilers. Target operating temperature would shift from 165 to 145°F. See below.

•

Boiler #1 St1=160, E6=17.0, S6=24.0, Sb6= -20

•

Boiler #2 St1=160, E6=17.0, S6=24.0, Sb6= -25

•

Boiler #3 St1=160, E6=17.0, S6=24.0, Sb6= -25

•

Boiler #1 St1=160, E7=0.0, S7=24.0, Sb2= -25

•

Boiler #2 St1=160, E7=0.0, S7=24.0, Sb2= -20

•

Boiler #3 St1=160, E7=0.0, S7=24.0, Sb2= -25

•

Boiler #1 St1=160, E1=0.0, S1=24.0, Sb1= -25

•

Boiler #2 St1=160, E1=0.0, S1=24.0, Sb1= -25

•

Boiler #3 St1=160, E1=0.0, S1=24.0, Sb1= -20

•

Boiler #2 St1=160, E2=0.0, S2=6.0, Sb2= -20

•

Boiler #3 St1=160, E2=0.0, S2=6.0, Sb2= -25

•

Boiler #1 St1=160, E2=0.0, S2=6.0, Sb2= -25

LEAD/LAG CONTROL OPTION 2:

The lead-lag and outdoor reset function is managed by a third party Boiler Management System (BMS) or building

Energy Management System (EMS). This manner of control will only function to enable-disable the EMBLEM

®

boiler

system. Once enable the TempTrac

®

boiler control must be allowed to function independently in order to ensure efficient

operation. If outdoor reset is desired the TempTrac

®

outdoor reset function must be utilized and the programming

function must be identical to the BMS or EMS control.

See the TempTrac

®

Service & Setup Manual (34-81), for addition information on programming the outdoor reset

function.

Terminals R1 & R2 located in the control kiosk provide enable/disable electrical interface. Remove the jumper to

interrupt automatic control of the EMBLEM

®

boiler system.

Riverside Hydronics

®

, LLC - 990 Haltom Road - Fort Worth, Texas 76117 - Tel 1-800-990-5918

Friday

Saturday

Sunday

Monday