HeatStation™ CONDENSING WATER BOILER

12

34-1161 05/17

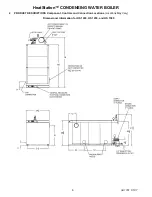

4.2 Sensor Locations and Thermal Well

The selection of the hydronic system design is explained in detail in Section 10 “Control Settings for Hydronic System

Design”.

The EOS control system on HeatStation comes configured for the

Multi Boiler Primary/Secondary

hydronic system.

The system sensor will automatically be selected for system temperature regulation. The system sensor along with a

thermal well is provided and wired to the control board (J2-5 & J2-4 common). If the system sensor is not to be used

for control, it can be left uninstalled. Only one system sensor is required when the Cascade function is enabled. The

PIPING parameter = P/S (SETUP MENU). In Cascade, the system sensor is installed on the MASTER boiler.

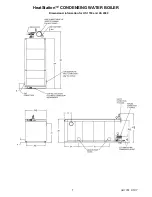

When HeatStation is applied in a

Multi Boiler Primary Only

hydronic system, the system sensor will also be used for

system temperature regulation. The system sensor along with the provided thermal well should be installed in the main

supply plumbing. Only one system sensor is required when the Cascade function is enabled. In Cascade, the system

sensor is installed on the MASTER boiler. Isolation valves are recommended for this system. When PIPING parameter

= VALV (SETUP MENU), the EOS will control the isolation valves. See the piping illustration in Section 4.

In a

Single Boiler Primary Only

installation the PIPING parameter = PAR (SETUP MENU). In this configuration

HeatStation can use either the supply sensor located in the upper piping manifold or the return sensor located in the

lower for operation as needed. As the HeatStation is shipped, the controlling sensor is the supply sensor. If return

sensor control is preferred, refer to Section 10 for instructions on how to configure the EOS control system for your

hydronic system and select the desired sensor location.

4.3 Filling the Boiler

1.

Fill the system with water. To be sure that the unit is not “air bound,” open the relief valve. Leave the valve open

until a steady flow of water is observed. Close the valve and complete filling the system.

2. In hard water areas, fill water should receive water treatment to reduce the introduction of minerals into the system.

Excessive buildup of minerals in the heat exchanger can cause a non-warrantable failure.

3. Make sure there are no system leaks. DO NOT use petroleum based stop-leak products. All system leaks must

be repaired. The constant addition of make-up water to a closed loop boiler system can cause minerals to collect

in the heat exchanger. Excessive buildup of minerals in the heat exchanger can cause a non-warrantable failure.

4. For systems requiring freeze protection, use only hydronic system antifreeze with a maximum concentration of

50%. Follow the glycol manufacturer’s instructions. DO NOT use uninhibited or automotive type antifreeze.

4.4 Building Return Temperature

The HeatStation can safely use plastic venting in systems that use colder building return water throughout the year.

Higher building return water temperatures, or systems which reset to higher temperatures in cold weather may require

the use of stainless steel venting.

See Section 8 “Venting” regarding the selection of vent materials based on maximum

operational temperatures.