HeatStation™ CONDENSING WATER BOILER

15

34-1161 05/17

6

GAS SUPPLY AND PIPING

Verify the type of gas specified on rating plate is supplied to the unit. This unit is orificed for operation up to 2000 feet

altitude. Appliance Btu/h input derates 4% per 1000 feet elevation above sea level. Consult Factory for installations

above 2000 feet elevation.

6.1 Gas Train and Controls Certification

NOTE

: The gas train and controls assembly provided on this unit have been tested under the applicable Nationally

Recognized Standard to comply with safety and performance criteria such as ignition, combustion and safety shutdown

operation.

6.2 Gas Control Trains

All models include the following gas control train components: manual shutoff valve, a combination gas valve

containing two safety shutoff valves, an internally vent limited zero governor type regulator, a manual test valve and

manifold pressure taps, and high and low gas pressure switches.

WARNING: Do not adjust or remove any screws or bolts on gas train control components which are secured

with a red or blue sealing compound. In addition to voiding warranties and certification listings, such

adjustment or disassembly can cause improper operation which could result in property damage, personal

injury or death.

6.3 Inlet Pressure

Measure at the inlet pressure tap located at the main gas cock. The inlet pressure must remain within the minimum

and maximum values while the unit is at rest and while the unit is operating at maximum firing rate.

6.4 Manifold Pressure

Measure at the pressure tap located downstream side of the manual valve closest to the burner. The rated manifold

pressure appears on the product data label located near the front of the appliance.

6.5 Gas Piping Size

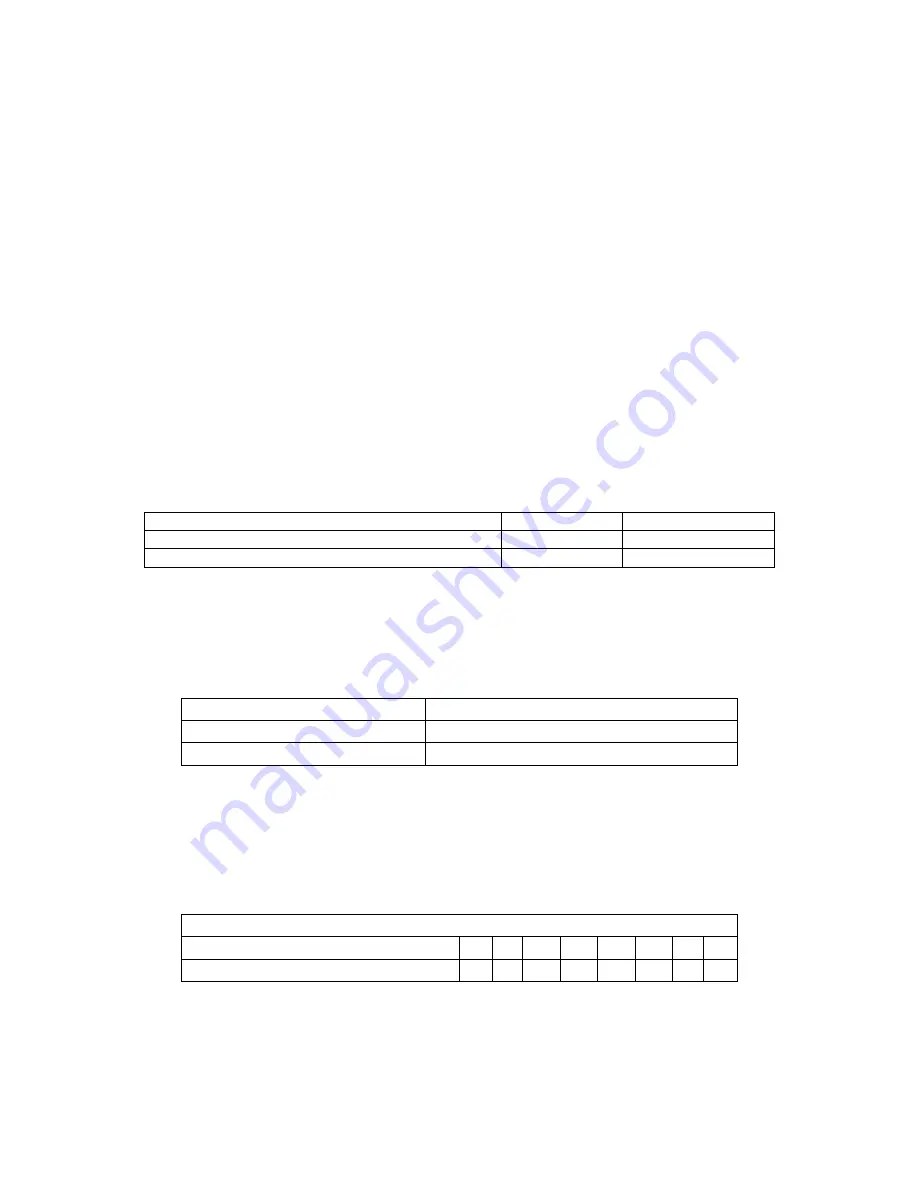

The following table identifies the gas connection size.

MODEL

SIZE NPT

1000 & 1250 HS

1"

1500, 1750 & 2000 HS

1½"

Do not use the gas pipe connection size to determine the gas supply piping. Designing and sizing a gas supply piping

system requires consideration of many factors and must be done by a gas supply piping expert. Always follow NFPA

54 National Fuel Gas Code for gas pipe sizing and gas pipe system design. The following charts provide examples of

some of the information used by the gas supply piping expert to determine proper pipe sizes.

Use the values in the following table to add the equivalent straight pipe for each elbow or tee to obtain the total distance

from the meter:

INLET PRESSURE

NAT. GAS

Propane

Maximum Static Pressure (Inches-Water Column)

14.0"

13"

Minimum Flow Pressure (Inches-Water Column)

3.5"

8"

CONVERT FITTINGS TO EQUIVALENT STRAIGHT PIPE*

Diameter Fitting (inches)

¾" 1" 1¼" 1½" 2"

3"

4"

5"

Equivalent Length of Straight Pipe (feet) 2'

2'

3'

4'

5'

10' 14' 20'