HeatStation™ CONDENSING WATER BOILER

20

34-1161 05/17

8

VENTING

All HeatStation models use the positive pressure generated by the burner system blower to push combustion products

out of the vent. Since the vent system is under positive pressure and must be capable of containing condensate, it

must be constructed using schedule 40 solid PVC or CPVC pipe or using a Polypropylene or Stainless Steel venting

system (single or double wall) listed by ETL, UL, ULC or CSA for Category IV positive pressure gas appliance venting.

Do not use ABS pipe and do not use PVC or CPVC pipe with cell/foam type construction (such

as “CellCore”) or other

non-solid PVC or CPVC plastic pipe.

WARNING: Vent piping must be supported to prevent transferring load to the vent connection. Failure to

properly support vent piping can damage the vent connection which can result in failure of the venting system

and/or exposure to carbon monoxide or other toxic fumes, which can result in property damage, personal

injury or death.

Chaudières HeatStation sont conçus pour fonctionner avec le PVC, CPVC ou en polypropylène ou simple ou double

paroi en acier inoxydable système indiqué par ETL, UL, ULC ou CSA pour la catégorie IV pression positive appareil à

gaz évacuation de ventilation. Ne sélectionnez pas la taille du tuyau de ventilation basée uniquement sur le diamètre

raccord de l'appareil.

WARNING: Use only solid PVC or CPVC pipe or use a Polypropylene or Stainless Steel venting (single or

double wall) system listed by a nationally recognized testing laboratory for Category IV positive pressure gas

appliance venting. Use of ABS pipe, or use of PVC or CPVC pipe with cell/foam type construction or use of

use of venting materials other than specified in these instructions can result in failure of the venting system

and/or exposure to carbon monoxide or other toxic fumes, which can result in property damage, personal

injury or death.

8.1 Vent Material Selection

The HeatStation can safely use plastic venting in systems that use colder building return water throughout the year.

Higher building return water temperatures, or systems which reset to higher temperatures in cold weather can require

the use of stainless steel venting. For safe operation, the vent system material must be selected according to the

maximum building return water temperature. Once the vent material has been selected, follow all of the requirements

in Section 8.2 Vent Installation

– General and all of the requirements for the selected vent material located in either

Section 8.3 PVC Vent Installation or Section 8.4 CPVC Vent installation or Section 8.5 Polypropylene or Stainless

Steel Vent Installation.

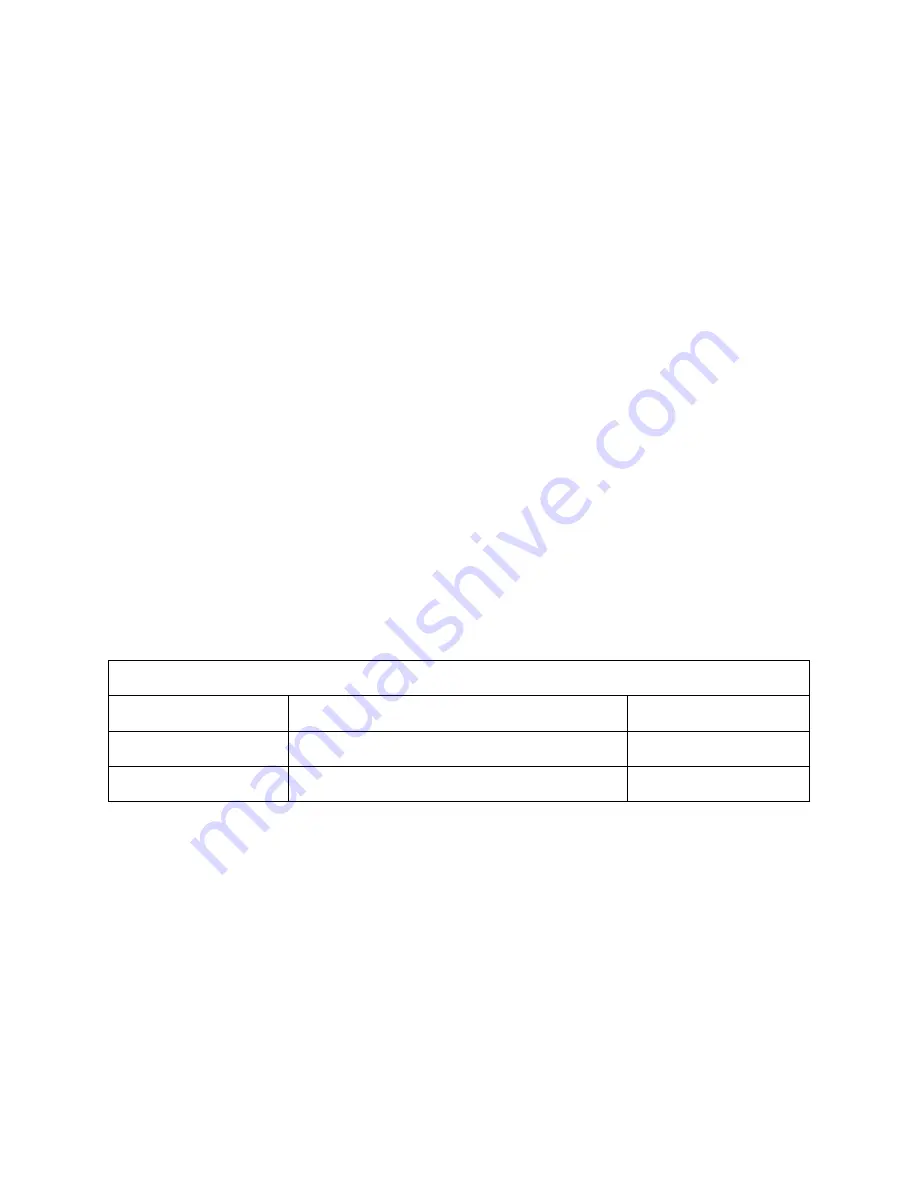

VENTING MATERIAL SELECTION BASED ON

BUILDING RETURN WATER TEMPERATURE

Vent System Material

Specified**

Maximum Return Water Temperature

Other Allowable Vent

System Materials**

PVC

Up to 140ºF (60ºC)

CPVC, Polypropylene*

or Stainless Steel*

CPVC, Polypropylene*

or Stainless Steel

Return temperatures greater than 140ºF (60ºC)

-

* Polypropylene and Stainless Steel venting systems must be ETL, UL, ULC or CSA listed as Category IV.

** The Vent Limit Switch is set to protect PVC vent system material. Higher temperature rated vent materials can be used, but the

maximum allowed return water temperature for the vent material specified is unchanged, unless the Vent Limit Switch is adjusted

for the higher temperature rating allowed by these vent materials (Contact factory for instructions).

NOTE:

The HeatStation boiler ships with a Vent Limit Switch that will keep the boiler from operating with a flue gas

temperature that exceeds the maximum allowable temperature of PVC vent material. If the return water temperature

is above 140°F, then solid CPVC or ETL, UL, ULC or CSA listed polypropylene or stainless steel venting is required

and the vent limit switch must be adjusted for the higher temperature rating allowed by these vent materials (Contact

factory for instructions).