HeatStation™ CONDENSING WATER BOILER

37

34-1161 05/17

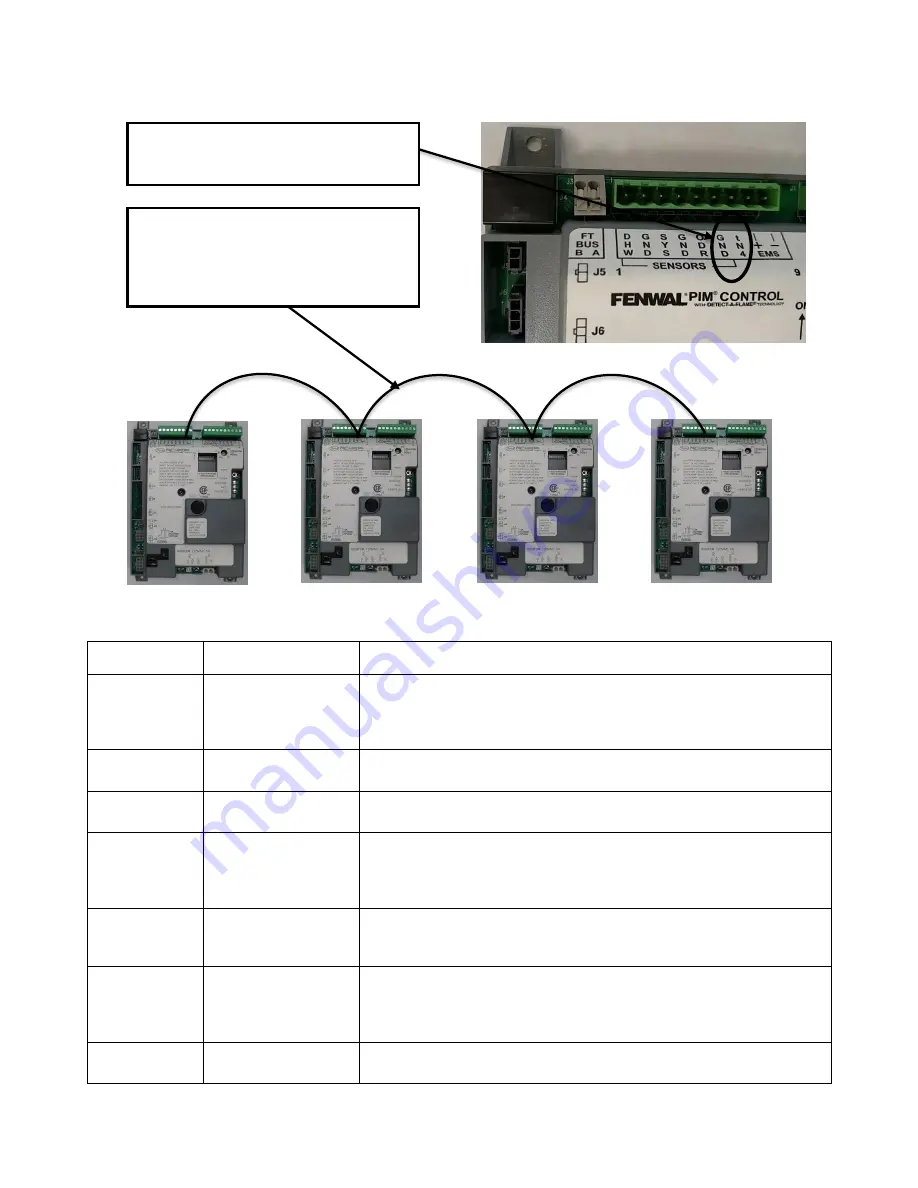

The following illustration shows how to establish a communication link between boilers:

The following parameters are used to set up your cascade operation. When boiler #1 is assigned the MSTR (Master)

identifier, Cascading will automatically be activated.

Parameter

Range

Description

ADDRESS

NONE, MSTR,

2,3,4…..,12

The ADDRESS parameter will assign a unique identifier to each

boiler. Boiler #1 should be assigned MSTR (Master). The MSTR boiler

will initiate the cascade control commands. Each consecutive boiler

should be assigned a number.

PIPING

P/S, PAR, VALV

When setting up a Cascade system, always select the P/S

(Primary/Secondary) piping regardless of the actual installed system.

CONDENSE

OFF, ON

This parameter should be preset to ON for the Heatstation but the

correct state should be verified during setup.

MOD COND

50 to 100%

For Parallel modulation, this parameter will select the burner

modulation percentage, once reached, will trigger the next boiler to

be enabled. When adjusted to 100%, cascade function effectively

becomes Sequential.

FIXED LEAD

OFF, ON

When all the boilers in the system are either condensing or non-

condensing, this parameter, when enabled will select a fixed lead

boiler.

ROT COND

OFF, ON

This parameter turns on rotation for the condensing boiler group in a

mixed system of condensing and non-condensing boilers. When

enabled, the lead boiler will be rotated every 48 hours. Consult factory

when designing such a system for additional guidance.

ROT NC

OFF, ON

This parameter turns on rotation for the non-condensing boiler group

in a mixed system.

The tN4 and GND terminals are the

communication point for the PIM.

Terminal tN4 and GND should be

connected in a daisy chain manner to

each between each boiler. Polarity

mush be respected.