HeatStation™ CONDENSING WATER BOILER

9

34-1161 05/17

back of the boiler. The HeatStation can be installed directly on a combustible floor, but not on carpet.

Distance minimale aux matériaux combustibles est égale à zéro (0 cm) sur les haut, côtés et à l'arrière, avant les 61

cm et peut être installé directily sur un plancher combustible.

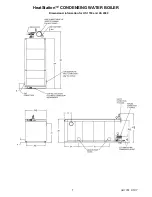

3.6 Service Clearances

Additional clearance beyond the minimum required to combustible material should be considered to facilitate easy

access for inspection and service of items such as the burner, gas controls and plumbing connections. Also allow

sufficient space for installing and servicing building water, gas, vent, combustion air, electrical, pump and other

auxiliary/optional equipment and connections.

3.7 Other Code and Regulatory Clearances and Requirements

Additional clearance beyond the minimum required to combustible materials and service recommendations may be

required to comply with local, state or national codes and regulations. It is to the responsibility of the installer to comply

with these requirements. Examples of codes or regulations that may apply are the National Electric Code,

State/Regional/National drain water and flue emissions regulations, the National Fuel Gas Code, Building Construction

and Safety Codes, the Americans with Disabilities Act (ADA) and

”Safety Code for Controls and Safety Devices for

Automatically Fired Boilers” (CSD-1) and other applicable Boiler Installation Code and Regulatory requirements.

4

GENERAL PIPING GUIDELINES

4.1 Supply and Return Connections

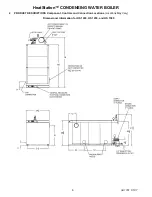

1. Connect the boiler system return piping (water to be heated) to the

“Return” fitting located near the bottom and rear

of the boiler.

2.

Connect the system supply piping (hot water out of the unit)) to the “Supply” fitting located near the top and rear of

the boiler.

3. Install shut-off valves and unions on the Return and Supply piping for servicing. Use caution when threading pipe

nipples into tank connections to prevent cross threading, or over-tightening. Always use a back-up wrench on tank

nipples when tightening unions, valves, etc.

4. Take those steps necessary to avoid the risk of boiler water freezing in the boiler or system piping (such as adding

glycol (up to 50%), insulating pipes, heat trace, etc.).

5. Pipe the drain valve to a suitable open drain capable of receiving discharge temperatures up to 212ºF.