Aluminum Base Angle

Aluminum Base

Angle

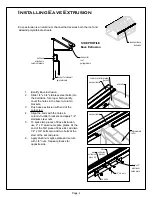

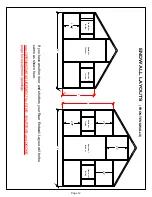

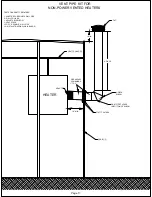

1. Identify the 2''x 3'' Aluminum Base Angle (ABA).

2. Place ABA against the side groundrails (3'' down 2'' up)

2"

3"

3. Slide the ABA past the end of the groundrail 3''. Mark on

the 2'' side of the angle where the groundrail ends and cut

2'' side on the line. The 2'' side of the ABA will be flush

with the groundrail, and the 3'' side will hang past the

groundrail 3''.

base angle

profile

2''

3''

cut line

3"

over hang

3"

4.

After notching the initial piece of ABA, continue placing angle end to end down the side

groundrail. Repeat notching process at opposite end of greenhouse.

*Remember* when

cutting ABA at opposite end of greenhouse, DO NOT cut the ABA flush with groundrail.

Cut 3'' longer than groundrail and notch the 2'' side back 3'' see detail A.

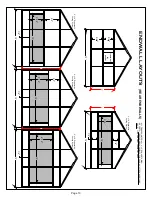

5. Lay ABA across the front & rear of the greenhouse. Place a piece of ABA against the 3'' over

hang at the corner of greenhouse. Make sure that the ABA is held against the front groundrail,

mark the ABA at the door stud and cut off flush with the inside edge of door stud

see 5a

.

Repeat for opposite side of door and rear of greenhouse.

If you do not have a door in the rear

of greenhouse, lay ABA end to end to equal the width of the greenhouse.

over hang

3"

detail A.

3.

4.

5.

5a.

ABA

angle

end to end

rear groundrail

corner leg

ABA

corner leg

front groundrail

ABA

side groundrail

side groundrail

side groundrail

red = ABA cut flush with door stud

door stud

endwall stud

corner leg

front groundrail

door opening

ABA flush against

3''overhand

Page 19

Summary of Contents for Thoreau Series

Page 2: ......