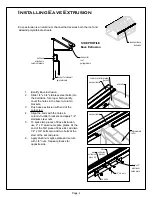

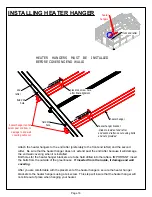

ATTACHING THE INTERMEDIATE RAFTER EXTRUSION

2

3

Ridge Base

Ridge

Base

Flange

Rafter Extrusion

4

5

6

Intermediate Rafter

Extrusion

Tek-screw

Attaching

Ridge Base

Hip

Begin by measuring from the hip of the ridge base extrusion down to the

edge of the eave extrusion along the top of the rafter. Use the

measurement to cut the intermediate rafter extrusion to the appropriate

length.

(Ridge cap will already be attached at this point but not

shown in photo #1 to help better explain how to install the

intermediate rafter extrusion).

Starting at the top, lay the Intermediate rafter extrusion over the flange

of the ridge base extrusion allowing the tek-screw in the ridge base

extrusion to fit inside the slot located on the underside of the

intermediate rafter extrusion.

(See photo #1 & Fig. E).

Be sure that the Intermediate rafter extrusion is pushed up against the

hip of the ridge base extrusion and insert two tek-screws through the

Intermediate rafter and through the flange of the ridge base extrusion.

(See photos 1 - 3 & the drawing @ the bottom of this page).

1

Working your way down, conform the Intermediate extrusion to the shape

the rafter, while inserting two tek-screws 12 to 16 inches apart down the

full length of the rafter.

(See all photos).

Eave Extrusion

Intermediate

Rafter

Extrusion

Two tek-screws side by

Intermediate

Rafter

Fig. E

Page 23

Summary of Contents for Thoreau Series

Page 2: ......