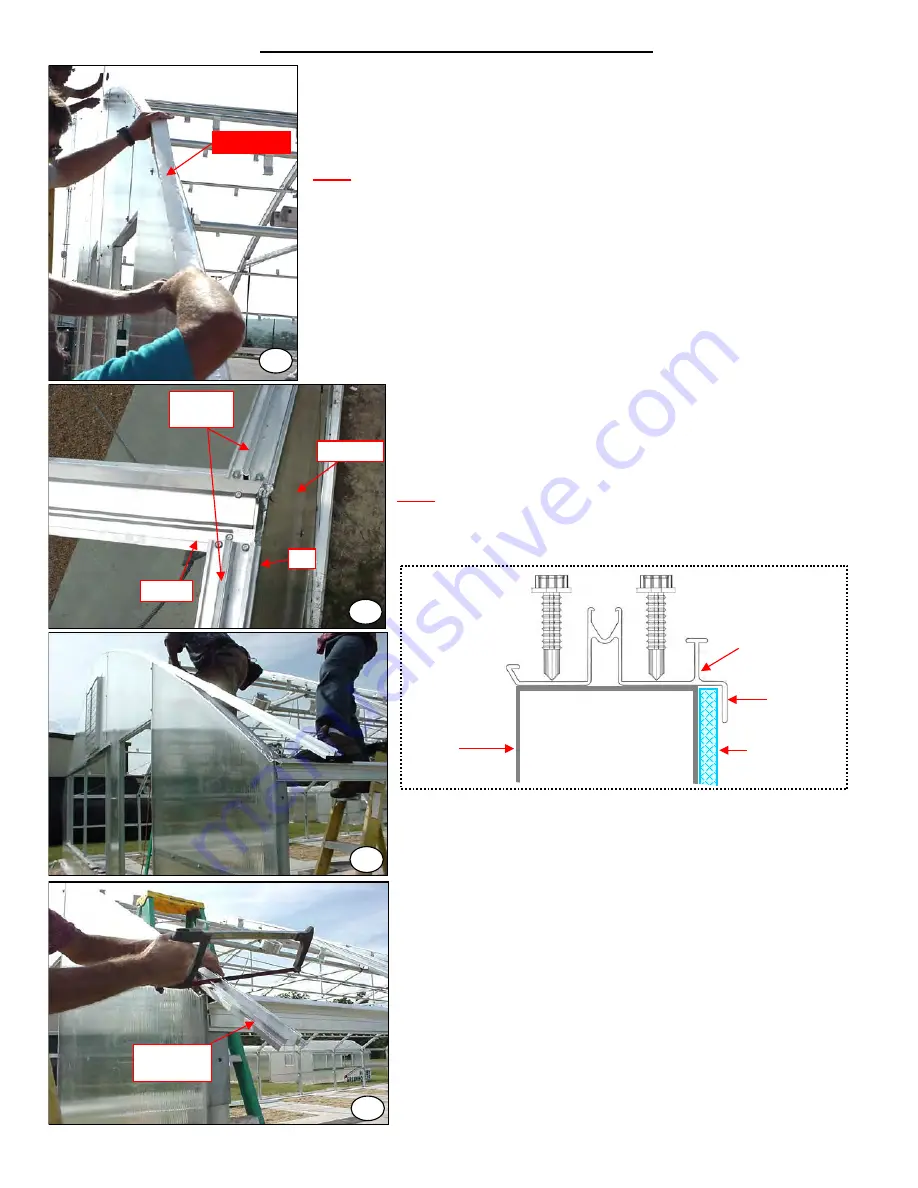

ATTACHING END RAFTER EXTRUSION

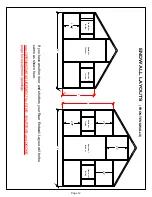

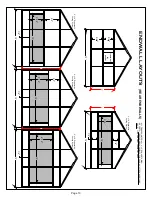

1

3

2

4

Apply foil tape to the top of the end rafter, allowing it to over-lap the top edge of

the P.C.S.S. endwall covering. This prevents moisture, caused by condensation

from collecting between the two layers of the P.C.S.S. covering.

(See photo #1)

Note:

Before attaching the end rafter extrusion, be sure the ends of the ridge

base extrusion are covered with foil tape.

Foil Tape

Flange

P.C.S.S.

Starting at the top, lay the end rafter extrusion over the flange of the

ridge base extrusion making sure that the lip is turned down lapping

the P.C.S.S. endwall covering. Butt the end rafter extrusion up to

ridge base extrusion and insert two screws into the end rafter

extrusion, through the flange of the ridge base extrusion as shown

in

photo #2. (Also see Fig. F)

Note:

The groove under the end rafter extrusion is not large enough

to except the tek screw in the ridge base flange as was with the

intermediate rafter extrusion.

End Rafter

Extrusions

Lip

Working your way down, conform the extrusion to the shape of the

rafter, while inserting two tek-screws 12 to 16 inches apart down

the full length of the rafter.

(See photo #3)

Cut off the excess, making sure that the end rafter extrusion stops

flush with the edge of the eave extrusion.

(See photo #4)

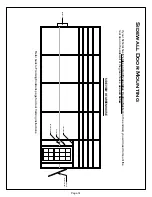

Eave Extrusion

End Rafter

End

Rafter

Extrusion

Twin Wall

( P.C.S.S.)

Lip

End

Rafter

Ridge Cap

Ridge Base

Fig. F

Page 26

Summary of Contents for Thoreau Series

Page 2: ......