11

7.

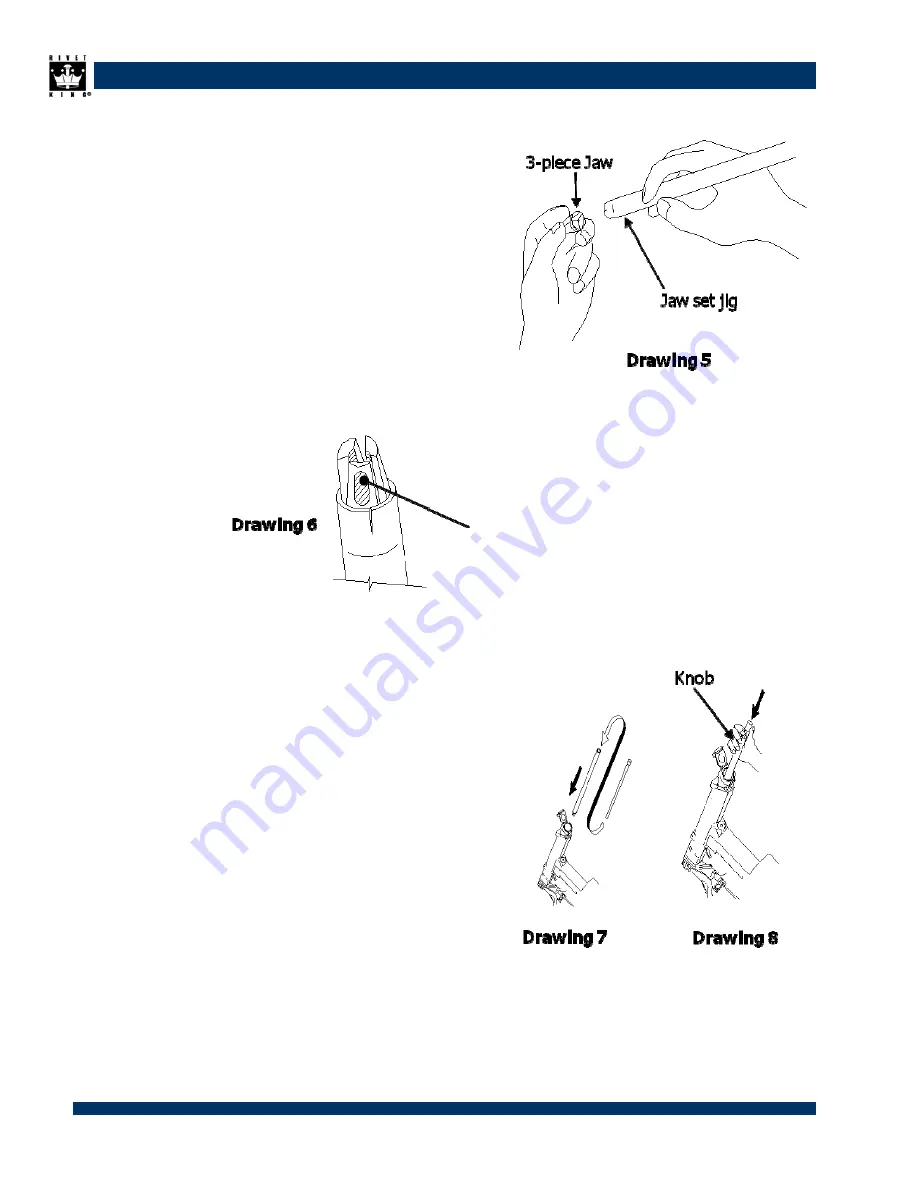

Insert 3 jaws into the tip of the tube on the

the outside of the jaw Setting Jig.

(Drawing 5, Drawing 6)

As shown in Drawing 6, apply an

over-the-counter Molybdenum grease.

(Note that applying grease to the jaw

teeth will cause the teeth to slip on the

rivets, and may make riveting impossible ).

Apply grease here

8.

Insert the jig, as shown in (Drawing 7).

Stop it about 5mm before it touches the end,

and press the knob on the inside of the tube.

(Drawing 8 )

Summary of Contents for RK-4500

Page 17: ...17 TROUBLESHOOTING RK 4500 Trouble Countermeasures...

Page 27: ...27...

Page 28: ...28...