- 7 -

10)

Adjust revolvable air supply into any required position and connect the tool to the source of the

compressed air.

11)

Put the rivet on the mandrel and push towards the anvil, this will screw on the rivet.

12)

Put the screwed rivet into the prepared hole.

13)

Press the trigger and the rivet will be riveted in.

14)

Relieve the trigger, the mandrel will screw out from the rivet (if it is not fully screwed out, use the

unscrewing button).

15)

Check the fastened rivet

-

if the rivet is not fully fastened it is necessary to increase the stroke.

-

if the rivet is too fastened, which results in deformation of the rivet and the mandrel is hard to

unscrew out from the rivet, it is necessary to decrease the stroke.

16)

Check the setting‐up of the anvil according to the step 8).

The tool, which is set up a prepared this way is ready for riveting.

3. TOOL MAINTENANCE

During maintenance the tool must be disconnected from the source of compressed air!!!

3.1. Daily maintenance

Before starting work, apply several drops of lubricating oil (we recommend hydraulic oil HYSPIN AWHM 32

CASTROL) into the air inlet of the tool, on condition there is no lubricating device connected in the air

distribution.

Check the tool for air leakage, if necessary replace damaged hoses and clasps.

If the pressure regulator is not equipped with a filter, blow through the air hose before its connection to the

tool in order to get rid of impurities and water. If the pressure regulator has a filter, dry it out.

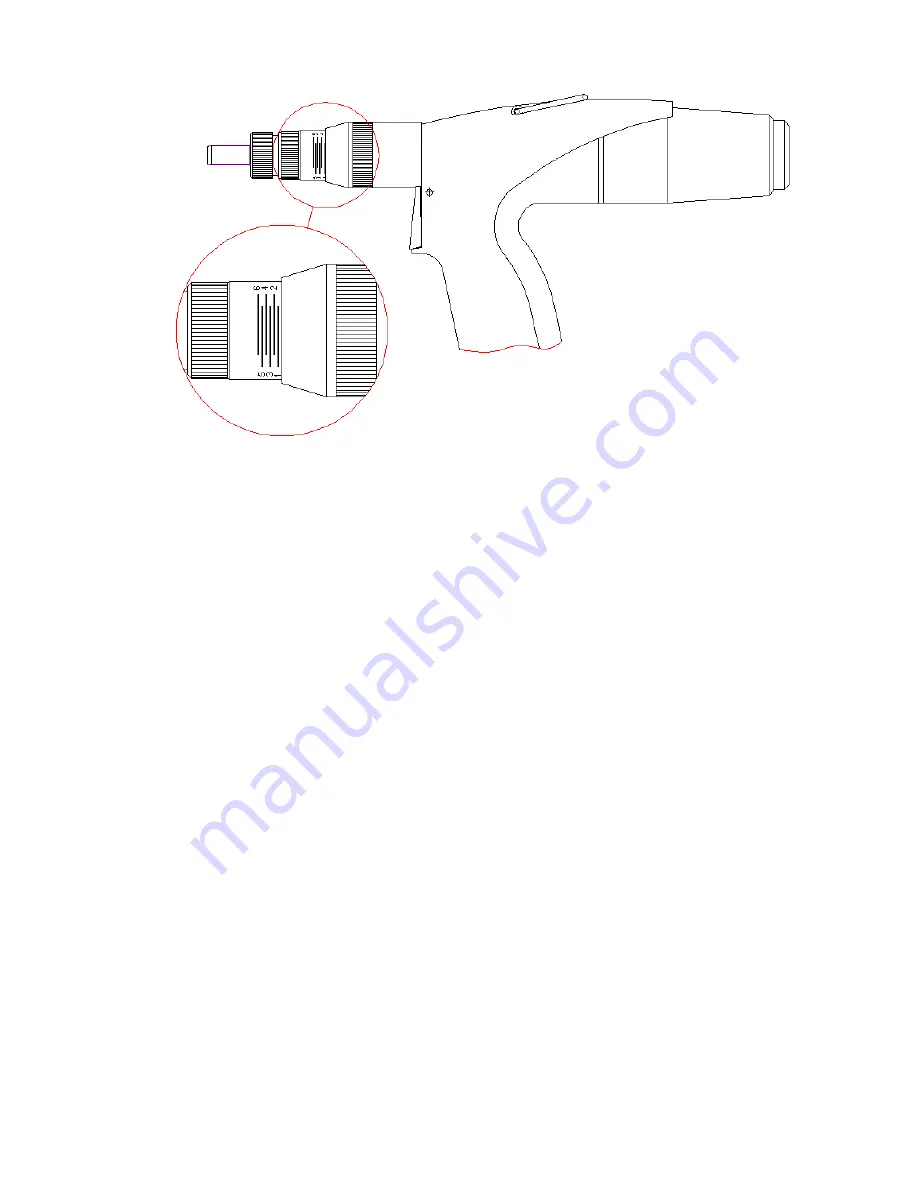

Check whether the fixed nose‐piece corresponds to the BR diameter and that all screw threads and joints are

tightened properly.

Check whether the air outlets are really empty.