RIX Industries

040910-01

Page 8

4.4

Control logic Description

The following explains the logic sequence as reflected on the electrical schematic (

Figure 16

in

Appendix):

1.

With power applied to the unit and the HOA selector switch (HOA) in HAND, push

the START pushbutton.

2.

The two pressure switches, suction (PSIL) and discharge (PSR) are connected in

series to the motor controller. If the suction pressure is high enough to close the

suction pressure switch, and the discharge switch remains closed (pressure below

the switch "closed" setting) the compressor will start.

3.

Current passes through the two closed pressure switches, the closed time delay

relay (TDR), and energizes the starter coil (C-1). The starter coil starts the main

drive motor. The fan motor and hour meter also operate at this point. The green

light (LG) will energize indicating the compressor is running. Tripping of either the

suction or discharge switch will break current to the coil (TDR) which will stop the

drive motor.

4.

The compressor may also be run in the automatic mode by selecting AUTO on the

HOA switch. All features are the same as described above except that after the inlet

or discharge switch shut down the unit, the compressor will automatically restart

when the switches are moved to the "closed" setting. The compressor will continue

cycling until the selector switch is moved to either HAND or OFF.

5.

The unit may be stopped at any time by switching the HOA to OFF.

4.5

Safety Device Set Points

The following safety devices have been provided at the set points noted below. Pressure switch

settings may be adjusted to User’s needs but set points shall not exceed the design constraints given

in

Compressor Specifications

. Do not adjust relief valve settings.

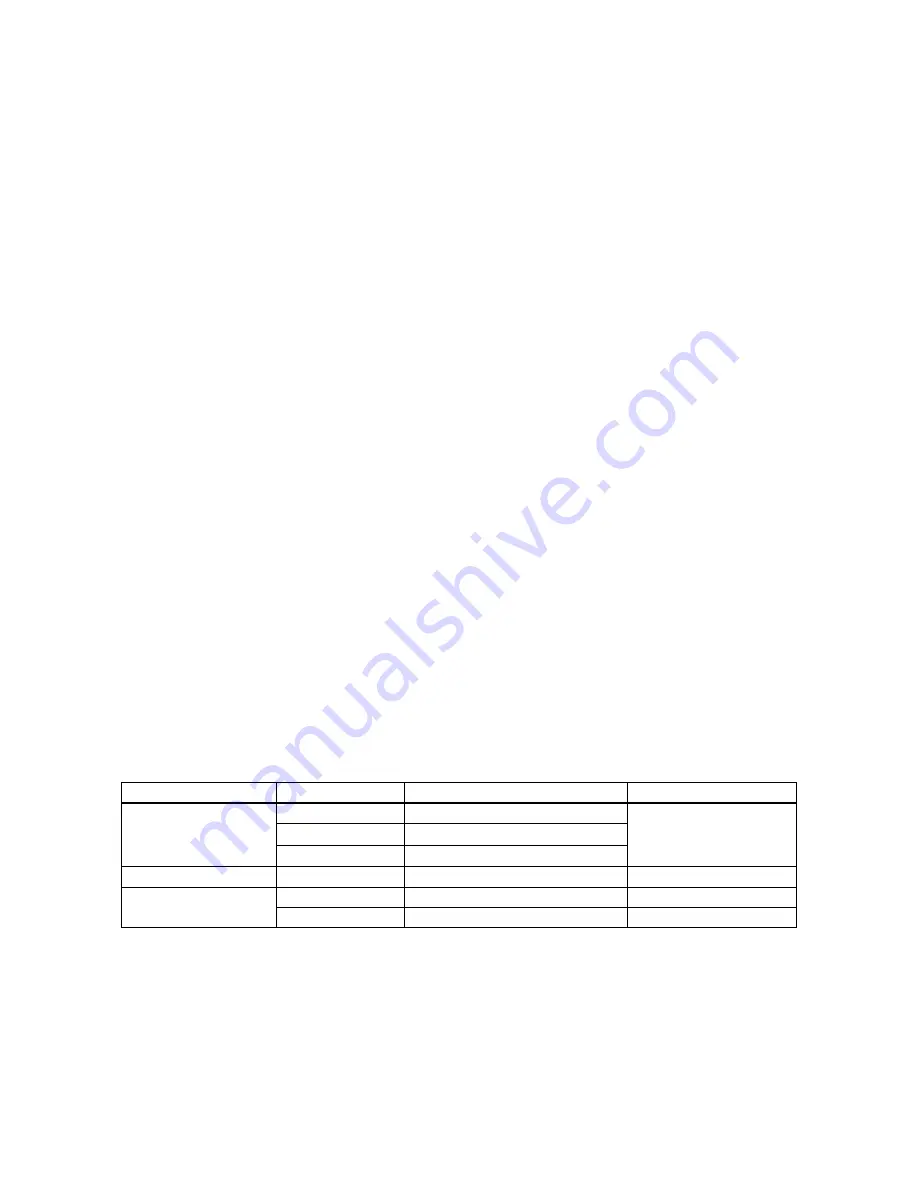

Device

Stage

Set Point

Function

Relief Valve

Suction

75 psig

Relieve excess

pressure build up

Interstage

700 psig

Discharge

2200 psig

Motor Overload

N/A

Motor FLA

Shutoff

Pressure Switch

Suction

25 falling

Shutoff

Discharge

2200 rising

Shutoff

Summary of Contents for 2PS-15-115

Page 37: ...RIX Industries 040910 01 Page 28 FIGURE 1 COMPRESSOR CROSS SECTION FASTENER DETAIL ...

Page 38: ...RIX Industries 040910 01 Page 29 FIGURE 2 COMPRESSOR CROSS SECTION PUMP DETAIL ...

Page 39: ...RIX Industries 040910 01 Page 30 FIGURE 3 1ST STAGE VALVE DETAIL ...

Page 40: ...RIX Industries 040910 01 Page 31 FIGURE 4 2ND STAGE VALVE DETAIL ...

Page 41: ...RIX Industries 040910 01 Page 32 FIGURE 5 EXTERIOR FASTENER DETAIL ...

Page 42: ...RIX Industries 040910 01 Page 33 FIGURE 6 MOTOR AND CONTROL BOX MOUNTING ...

Page 43: ...RIX Industries 040910 01 Page 34 FIGURE 7 SUCTION PLUMBING DETAIL ...

Page 44: ...RIX Industries 040910 01 Page 35 FIGURE 8 INTERSTAGE PLUMBING DETAIL ...

Page 45: ...RIX Industries 040910 01 Page 36 FIGURE 9 FINAL DISCHARGE PLUMBING DETAIL ...

Page 46: ...RIX Industries 040910 01 Page 37 FIGURE 10 COOLING FAN SUB ASSEMBLY DETAIL ...

Page 47: ...RIX Industries 040910 01 Page 38 FIGURE 11 BELT INSTALLATION DETAIL ...

Page 48: ...RIX Industries 040910 01 Page 39 FIGURE 12 GUARD MOUNTING DETAIL ...

Page 49: ...RIX Industries 040910 01 Page 40 FIGURE 13 CONTROL BOX DETAIL 1 OF 2 ...

Page 50: ...RIX Industries 040910 01 Page 41 FIGURE 14 CONTROL BOX DETAIL 2 OF 2 ...

Page 51: ...RIX Industries 040910 01 Page 42 FIGURE 15 CONTROL BOX WIRING DIAGRAM ...

Page 52: ...RIX Industries 040910 01 Page 43 FIGURE 16 ELECTRICAL SCHEMATIC ...

Page 53: ...RIX Industries 040910 01 Page 44 FIGURE 17 FLOW SCHEMATIC ...

Page 57: ......

Page 58: ......