RIX Industries

040910-01

Page 17

1.

Install new O-ring expanders, compression rings and rider rings on the pistons.

2.

Compress the rings by hand to ensure the rings fully sit in the piston grooves.

3.

Slide the cylinders over the pistons, taking care not to extrude the rings.

4.

Install the heads per

Section 7.3

.

5.

Rotate the flywheel by hand several times to ensure parts are free. See

Section 7.9

for

piston clearance adjustment.

7.7

Piston Assembly

The 1st stage piston assembly is installed with the connecting rod and retaining cap. This assembly

must be removed to service the connecting rod and all bearings.

To remove the 1st stage piston assembly, reference

Figure 2

and use the following procedure:

1.

Remove both heads and cylinders per

Sections 7.3

and

7.5

.

2.

Rotate flywheel to position the 1

st

stage piston at top dead center.

3.

Remove hex screw on bearing plate.

4.

Gently slide assembly outward by pulling connecting rod off crankshaft, allowing neck of

piston to pass through slot in crankcase. Move assembly to a clean surface for further

disassembly.

5.

With a pair of snap ring pliers, remove snap rings from wrist pin bore.

6.

Remove the wrist pin—the piston may require heating or a press to do so.

7.

Remove the connecting rod.

8.

Clean and inspect piston, wrist pin, and bearings for wear or damage. Wear must be within

the tolerance specified in

Section 7.10

.

To reinstall the 1st stage piston assembly:

1.

Install the connecting rod, wrist pin, and snap rings in the 1

st

stage piston assembly.

2.

Install the assembly on the compressor crankshaft.

3.

Install bearing plate and hex screw to fully secure the assembly to the crankshaft. Hex screw

must be secured with a small amount of Loctite primer and threadlocker (RIX P/N’s: 35-

8595 & 35-7641) and torqued to 180 in-lbs.

4.

Reinstall cylinders and heads per

Sections 7.3

and

7.5

.

Summary of Contents for 2PS-15-115

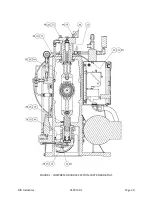

Page 37: ...RIX Industries 040910 01 Page 28 FIGURE 1 COMPRESSOR CROSS SECTION FASTENER DETAIL ...

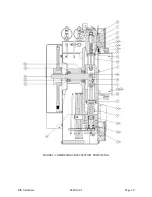

Page 38: ...RIX Industries 040910 01 Page 29 FIGURE 2 COMPRESSOR CROSS SECTION PUMP DETAIL ...

Page 39: ...RIX Industries 040910 01 Page 30 FIGURE 3 1ST STAGE VALVE DETAIL ...

Page 40: ...RIX Industries 040910 01 Page 31 FIGURE 4 2ND STAGE VALVE DETAIL ...

Page 41: ...RIX Industries 040910 01 Page 32 FIGURE 5 EXTERIOR FASTENER DETAIL ...

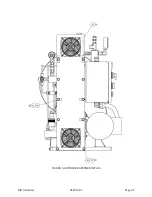

Page 42: ...RIX Industries 040910 01 Page 33 FIGURE 6 MOTOR AND CONTROL BOX MOUNTING ...

Page 43: ...RIX Industries 040910 01 Page 34 FIGURE 7 SUCTION PLUMBING DETAIL ...

Page 44: ...RIX Industries 040910 01 Page 35 FIGURE 8 INTERSTAGE PLUMBING DETAIL ...

Page 45: ...RIX Industries 040910 01 Page 36 FIGURE 9 FINAL DISCHARGE PLUMBING DETAIL ...

Page 46: ...RIX Industries 040910 01 Page 37 FIGURE 10 COOLING FAN SUB ASSEMBLY DETAIL ...

Page 47: ...RIX Industries 040910 01 Page 38 FIGURE 11 BELT INSTALLATION DETAIL ...

Page 48: ...RIX Industries 040910 01 Page 39 FIGURE 12 GUARD MOUNTING DETAIL ...

Page 49: ...RIX Industries 040910 01 Page 40 FIGURE 13 CONTROL BOX DETAIL 1 OF 2 ...

Page 50: ...RIX Industries 040910 01 Page 41 FIGURE 14 CONTROL BOX DETAIL 2 OF 2 ...

Page 51: ...RIX Industries 040910 01 Page 42 FIGURE 15 CONTROL BOX WIRING DIAGRAM ...

Page 52: ...RIX Industries 040910 01 Page 43 FIGURE 16 ELECTRICAL SCHEMATIC ...

Page 53: ...RIX Industries 040910 01 Page 44 FIGURE 17 FLOW SCHEMATIC ...

Page 57: ......

Page 58: ......