RIX Industries

040910-01

Page 19

To adjust the 2nd stage piston clearance, use the following procedure:

1.

Remove the 2nd stage head per

Section 7.3

.

2.

While holding the cylinder firmly in place, rotate crankshaft to ensure piston is at Top Dead

Center (TDC).

3.

Measure the clearance between the piston and the top of the cylinder liner. The

spool/guide cylinder may be threaded in or out to achieve a piston to cylinder clearance of

.012" to .016".

4.

Reinstall the head per

Section 7.3

.

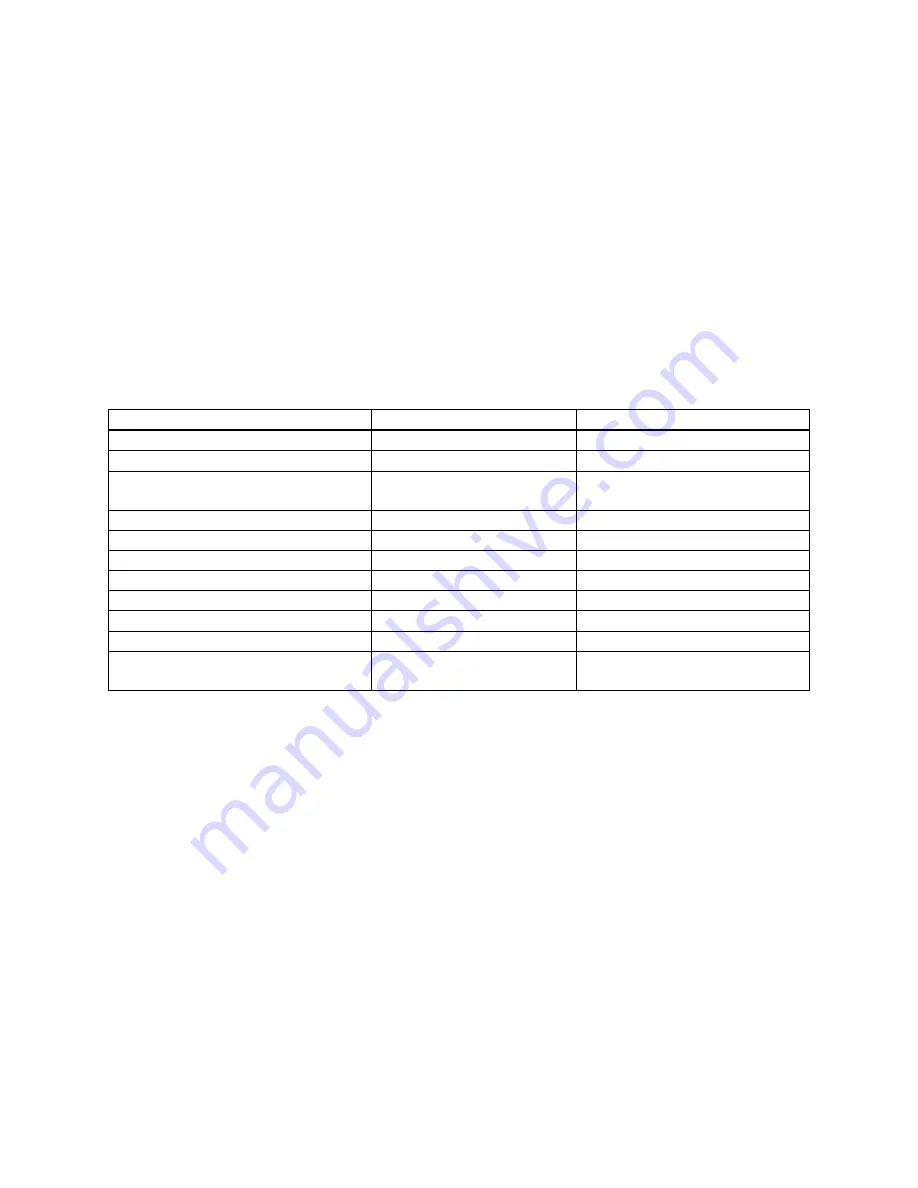

7.10

Clearances & Tolerances

Part

Nominal Dimension

Wear Limit

1

st

Stage Piston to Valve clearance

.011-.015”

Adjustable

2

nd

Stage Piston to Valve clearance

.012-.016”

Adjustable

Bearings

N/A

By inspection for knocking or

rough running.

Connecting Rod, Lower Bore

Ø3.146”

+.001”

Connecting Rod, Upper Bore

Ø0.687”

+.001”

Wrist Pin

Ø0.5000”

-.0005”

1

st

Stage Piston

Ø1.21”

Not a wearing part

1

st

Stage Cylinder

Ø1.251”

+.005”

2

nd

Stage Piston

Ø0.497”

-.003”

2

nd

Stage Cylinder

Ø0.501”

+.003”

Valves

-

Inspect for warping, scratches,

or pitting

7.11

Spare Parts

When ordering spare parts, ensure any gas wetted parts are ordered Oxygen cleaned by adding an

“X” prefix to the part number found in the appendix. Factory cleaned oxygen parts are denoted by

an “X” prefix at the beginning of the part number. It is the User’s responsibility to maintain the

cleanliness of factory cleaned parts and any existing portions of the gas stream that may be exposed

during installation or maintenance.

7.12

Connecting Rod Bearings

The connecting rod is aluminum, with a closed eye at the upper (larger) and lower ends (smaller).

The smaller closed eye houses a needle bearing that fits around the wrist pin. The larger closed eye

houses a ball bearing that fits around the crankshaft. These bearing are supplied with RIX grease

packed for life with Polyurea (RIX P/N 45-110) grease and

should be routinely inspected every

2000 hours maximum

. Note: it is critical to use this high-load, high temperature grease for the

connecting rod bearings. Bearing life will be significantly shortened if this grease is not used and

may result in rod breakage or other significant damage. Caution: This grease is non-oxygen

Summary of Contents for 2PS-15-115

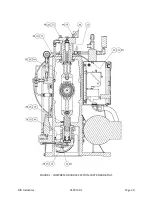

Page 37: ...RIX Industries 040910 01 Page 28 FIGURE 1 COMPRESSOR CROSS SECTION FASTENER DETAIL ...

Page 38: ...RIX Industries 040910 01 Page 29 FIGURE 2 COMPRESSOR CROSS SECTION PUMP DETAIL ...

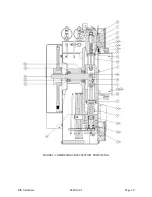

Page 39: ...RIX Industries 040910 01 Page 30 FIGURE 3 1ST STAGE VALVE DETAIL ...

Page 40: ...RIX Industries 040910 01 Page 31 FIGURE 4 2ND STAGE VALVE DETAIL ...

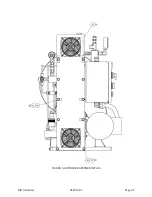

Page 41: ...RIX Industries 040910 01 Page 32 FIGURE 5 EXTERIOR FASTENER DETAIL ...

Page 42: ...RIX Industries 040910 01 Page 33 FIGURE 6 MOTOR AND CONTROL BOX MOUNTING ...

Page 43: ...RIX Industries 040910 01 Page 34 FIGURE 7 SUCTION PLUMBING DETAIL ...

Page 44: ...RIX Industries 040910 01 Page 35 FIGURE 8 INTERSTAGE PLUMBING DETAIL ...

Page 45: ...RIX Industries 040910 01 Page 36 FIGURE 9 FINAL DISCHARGE PLUMBING DETAIL ...

Page 46: ...RIX Industries 040910 01 Page 37 FIGURE 10 COOLING FAN SUB ASSEMBLY DETAIL ...

Page 47: ...RIX Industries 040910 01 Page 38 FIGURE 11 BELT INSTALLATION DETAIL ...

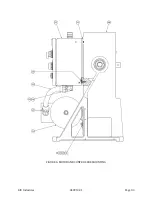

Page 48: ...RIX Industries 040910 01 Page 39 FIGURE 12 GUARD MOUNTING DETAIL ...

Page 49: ...RIX Industries 040910 01 Page 40 FIGURE 13 CONTROL BOX DETAIL 1 OF 2 ...

Page 50: ...RIX Industries 040910 01 Page 41 FIGURE 14 CONTROL BOX DETAIL 2 OF 2 ...

Page 51: ...RIX Industries 040910 01 Page 42 FIGURE 15 CONTROL BOX WIRING DIAGRAM ...

Page 52: ...RIX Industries 040910 01 Page 43 FIGURE 16 ELECTRICAL SCHEMATIC ...

Page 53: ...RIX Industries 040910 01 Page 44 FIGURE 17 FLOW SCHEMATIC ...

Page 57: ......

Page 58: ......