RIX Industries

040910-01

Page 16

4.

Install the valve seat into the 2

nd

stage head valve pocket, aligned with the pin and pushing

down squarely to engage the O-ring properly.

5.

Install pin and O-ring in the installed valve seat.

6.

Install the suction reed, aligned with the pin. Ensure the free end of the reed flap will sit

over the 4 round blind holes on the valve seat. Installing the reed upside down will result in

improper valve operation.

7.

Install valve stop and final O-ring in the 2

nd

stage valve pocket.

8.

Install the head per

Section 7.3.

7.5

Compression Cylinders

The compression cylinders must be removed to service the rings and pistons. The 2

nd

stage has a

removable liner. There is no scheduled maintenance required on the cylinder or liner.

Remove the 1

st

and 2

nd

stage compression cylinders referencing

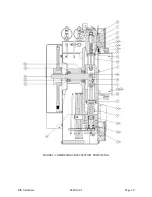

Figure 2

and using the following

procedure:

1.

Remove the head per

Section 7.3

2.

Rotate the flywheel to position the 1

st

stage piston at bottom dead center.

3.

Slide 1

st

stage cylinder off piston, using caution to prevent side loading the piston/rod

assembly and damage to the shims. It may be necessary to either lean back or elevate the

compressor to complete this task.

4.

Remove 2

nd

stage guide cylinder and liner.

5.

Clean and inspect the cylinder bore for wear or damage (see

Section 5.8

). Wear must be

within the tolerance specified in

Section 7.10

.

Reinstall the compression cylinder and liner in the reverse sequence of removal.

7.6

Compression Rings

To replace the compression rings, reference

Figure 2

and follow the instructions below:

1.

Remove the heads and cylinders per

Sections 7.3

and

7.5

. The 2

nd

stage piston will be lifted

out with the 2

nd

stage liner; remove the piston from the liner with a soft punch.

2.

Remove and discard the used compression rings, expanders, and rider rings. An O-ring pick

(P/N 88-5812) is helpful for removing used rings.

To reinstall the piston, follow the instructions below:

Summary of Contents for 2PS-15-115

Page 37: ...RIX Industries 040910 01 Page 28 FIGURE 1 COMPRESSOR CROSS SECTION FASTENER DETAIL ...

Page 38: ...RIX Industries 040910 01 Page 29 FIGURE 2 COMPRESSOR CROSS SECTION PUMP DETAIL ...

Page 39: ...RIX Industries 040910 01 Page 30 FIGURE 3 1ST STAGE VALVE DETAIL ...

Page 40: ...RIX Industries 040910 01 Page 31 FIGURE 4 2ND STAGE VALVE DETAIL ...

Page 41: ...RIX Industries 040910 01 Page 32 FIGURE 5 EXTERIOR FASTENER DETAIL ...

Page 42: ...RIX Industries 040910 01 Page 33 FIGURE 6 MOTOR AND CONTROL BOX MOUNTING ...

Page 43: ...RIX Industries 040910 01 Page 34 FIGURE 7 SUCTION PLUMBING DETAIL ...

Page 44: ...RIX Industries 040910 01 Page 35 FIGURE 8 INTERSTAGE PLUMBING DETAIL ...

Page 45: ...RIX Industries 040910 01 Page 36 FIGURE 9 FINAL DISCHARGE PLUMBING DETAIL ...

Page 46: ...RIX Industries 040910 01 Page 37 FIGURE 10 COOLING FAN SUB ASSEMBLY DETAIL ...

Page 47: ...RIX Industries 040910 01 Page 38 FIGURE 11 BELT INSTALLATION DETAIL ...

Page 48: ...RIX Industries 040910 01 Page 39 FIGURE 12 GUARD MOUNTING DETAIL ...

Page 49: ...RIX Industries 040910 01 Page 40 FIGURE 13 CONTROL BOX DETAIL 1 OF 2 ...

Page 50: ...RIX Industries 040910 01 Page 41 FIGURE 14 CONTROL BOX DETAIL 2 OF 2 ...

Page 51: ...RIX Industries 040910 01 Page 42 FIGURE 15 CONTROL BOX WIRING DIAGRAM ...

Page 52: ...RIX Industries 040910 01 Page 43 FIGURE 16 ELECTRICAL SCHEMATIC ...

Page 53: ...RIX Industries 040910 01 Page 44 FIGURE 17 FLOW SCHEMATIC ...

Page 57: ......

Page 58: ......