Rev E 4/08

A3534

INSTRUCTIONS FOR INSTALLING SPIRAL PISTON RINGS

ON FLOATING OR REMOVABLE PISTONS

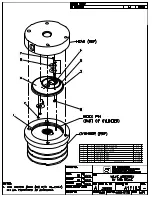

Refer to applicable piston assembly drawing in manual

Some compression stages use spiral wound compression rings. The pistons maybe be fixed to the rod and

removable, or floating. To replace the piston rings, remove the head per service manual instructions. With

the flywheel rotated to bring the piston to top dead center, unbolt and lift the cylinder up and over the

piston, or, if directed, pull the piston out of the cylinder.

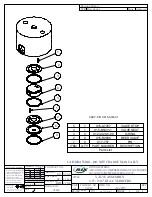

Inspect the piston for wear and replace if necessary. Replace all piston rings and O-rings. RIX does not

recommend partial replacement of rings.

1. Stretch the O-rings and roll them on one at a time using a seal tool (RIX P/N # 88-5812 or

equivalent). Alternately, roll o-rings onto the outside tapered portion of the sleeve tube provided

with the compressor (See Accessory Parts List for part number). Slide the sleeve tool over the

piston (to the farthest ring groove first) and roll the O-ring into the groove, taking care not to cut

the ring on sharp edge of the piston.

2.

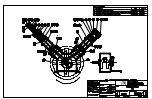

Before stretching or uncoiling the spiral piston ring,

note that each ring is slightly dish shaped.

The rings should be installed with the bottom of the dish down against the piston groove

land.

3. Gently stretch the piston ring and work it into the groove over the O- ring. Protect the thin ends of

the piston ring with your thumb nail while working the ring down into the groove. The last ¼ inch

of the spiral ring may be cut off if necessary.

4. Install the top and bottom rider rings, and pressure breakers if required. (note : additional spiral

rings can be substituted for pressure breakers )

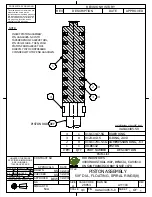

5. Slide the piston ring sleeve tool over the assembled piston, using the tapered end of the sleeve tool

to help compress the rings into the groove. (The bottom end of the piston should be inserted into

the tapered end tool, so it ends up on the non-tapered end) Gently work the sleeve tool onto the

piston, taking care not to pull out the thin ends of the piston ring.

6. After the piston has been installed in the compression sleeve tube, slide the piston back out and

examine the spiral rings. Replace any damage rings. Reinstall in sleeve.

7. When installing pistons into the top of the cylinder, place the squared end of the sleeve over the

Cylinder and press the piston into the top of the cylinder bore. The tapped hole in the piston

should be on top.

Summary of Contents for RIX 2V3B-4.1V Series

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 70: ...P N 515 910 P N 515 911 P N 515 792 P N 515 829 X515 910 X515 911 X515 792 X515 829...

Page 71: ......

Page 72: ......

Page 73: ...P N 76 713 X76 713...

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......