IMS01P06-E2

4

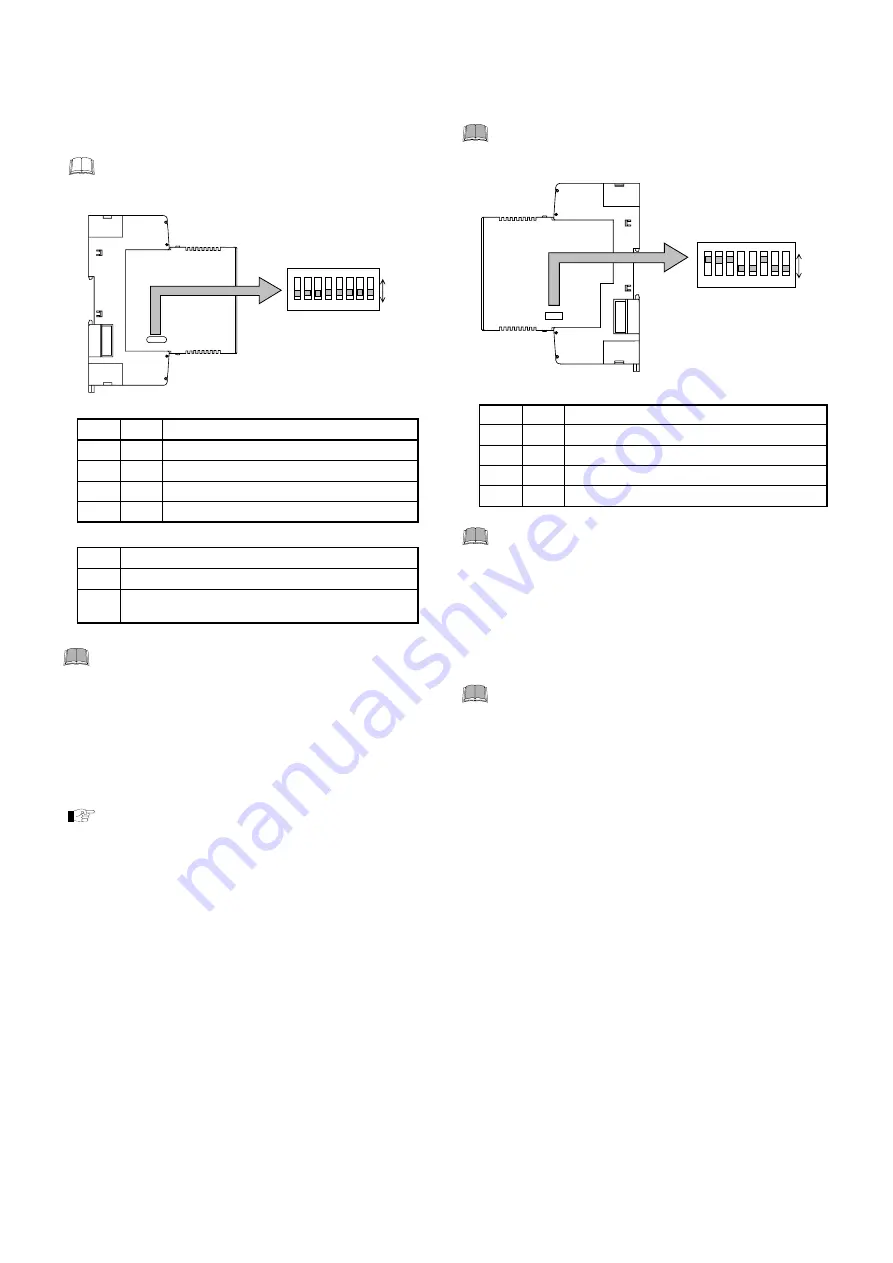

4.2 PROFIBUS/Host Communication

Transfer Setting

With the dip switch 1 which there is on the left side of module,

select PROFIBUS/Host communication transfer, communication

speed for internal communication in PROFIBUS.

Internal communication is communication that

V-TIO-G/V-TIO-H module conduct to other temperature

control modules in PROFIBUS.

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

ON

OFF

Left side (PROFIBUS side)

Dip switch 1

1

2

Internal communication speed

OFF OFF

38400

bps

ON OFF

9600

bps

OFF ON

19200

bps

ON ON

38400

bps

Factory set value: 38400 bps (1: OFF, 2: OFF)

7

PROFIBUS/Host communication transfer

OFF

PROFIBUS (Internal communication validity)

ON

Host communication (Internal communication

invalidity)

Factory set value: PROFIBUS (Internal communication validity)

Switch No. 3 to 6, 8: OFF fixed (Don’t change the

factory set values)

[Factory set value]

•

Internal communication speed:

38400 bps

•

Internal communication protocol: Modbus

[Factory set value of the dip switch 1]

No. 1: OFF

No. 5: OFF

No. 2: OFF

No. 6: OFF

No. 3: OFF

No. 7: OFF

No. 4: OFF

No. 8: OFF

For host communication

(

Modbus), see the

Module

Type Controller SRV Communication Instruction

Manual (IMS01P01-E )

.

4.3 Host Communication Setting

With the dip switch 2 which there is on the right side of module,

select communication speed for host communication.

When host communication is not used, dip switch 2

need not be set.

Dip switch 2

Right side (

temperature control side

)

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

ON

OFF

1

2

Host communication speed

OFF

OFF 2400

bps

ON

OFF 9600

bps

OFF

ON

19200

bps

ON

ON

38400

bps

Factory set value: 38400 bps

Switch No. 3 to 8: OFF fixed (Don’t change the

factory set values)

[Factory set value]

•

Host communication speed:

38400 bps

•

Host communication protocol: Modbus

[Factory set value of the dip switch 2]

No. 1: ON

No. 5: OFF

No. 2: ON

No. 6: ON

No. 3: ON

No. 7: OFF

No. 4: OFF

No. 8: OFF

When connecting two or more modules (V-TIO-A,

V-TIO-B, V-TIO-C or V-TIO-D) to the module (V-TIO-G

or V-TIO-H), match all of the switch No. 1, 2 settings

with the internal settings of the module (V-TIO-G or

V-TIO-H).