IMS01P06-E2

6

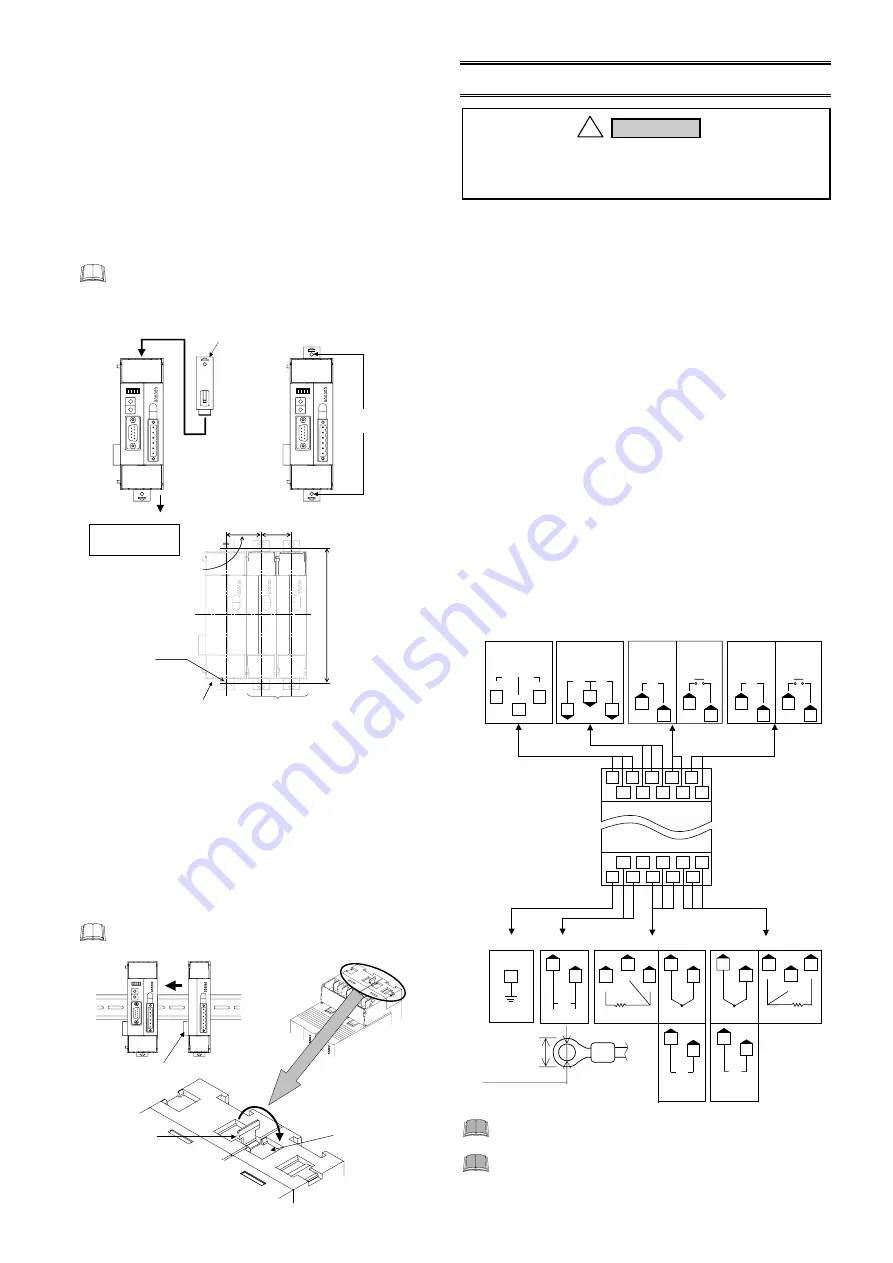

5.4 Panel Mounting

Mounting procedures

1.

Pull down the mounting bracket (A) until locked and that a

mounting hole appears.

2.

Prepare one mounting bracket per module (B) sold

separately (KSRX-55) and then insert it in the rear of the

terminal board at top of the module until locked but a

mounting hole does not disappear.

3.

Mount each module directly on the panel with screws which

are inserted in the mounting holes of the top and bottom

mounting brackets.

Recommended tightening torque: 0.3 N

⋅

m (3 kgf

⋅

cm)

The customer needs to provide the M3 size screws.

Select the screw length that matches the mounting

panel.

Mounting bracket

(Sold separately)

(A) Pull down

(B) Insert

(KSRX-55)

Mounting

holes

130.

5

±

0.

2

35.25

±

0.2

30

±

0.2

M3

Module of 40.5 mm wide

Module of 30 mm wide

5.5 Jointing Each Module

Up to 30 modules (V-TIO-A, V-TIO-B, V-TIO-C or V-TIO-D) can

be connected to one module (V-TIO-G or V-TIO-H).

Joint these

modules according to the following procedure.

Jointing procedure

1.

Mount the modules on the DIN rail and then joint these

modules together with the joint connector while sliding the

relevant module.

2.

Lift each of the joint tabs located at the top and bottom of the

module and then insert it in the slot of the adjacent module to

fix these two modules.

For panel mounting, first joint each module and then

mount it on the panel.

Joint tab

When viewed

from top

There is one joint tab at each

of the top and bottom of on

module. Therefore, fix two

adjacent modules with these

two joint tabs.

Joint tab

insertion slot

Joint connector

6. WIRING

6.1 Wiring Cautions

For thermocouple input, use the appropriate compensation

wire.

For RTD input, use low resistance lead wire with no

difference in resistance between the three lead wires.

To avoid noise induction, keep input signal wire away from

instrument power line, load lines and power lines of other

electric equipment.

If there is electrical noise in the vicinity of the instrument that

could affect operation, use a noise filter.

- Shorten the distance between the twisted power supply wire

pitches to achieve the most effective noise reduction.

- Always install the noise filter on a grounded panel.

Minimize the wiring distance between the noise filter output

and the instrument power supply terminals to achieve the

most effective noise reduction.

- Do not connect fuses or switches to the noise filter output

wiring as this will reduce the effectiveness of the noise filter.

Power supply wiring must be twisted and have a low voltage

drop.

For an instrument with 24 V power supply, supply power from

a SELV circuit.

6.2 Terminal Configuration

CT1

T/R(B)

SG

T/R(A)

RS-485

Internal communication

or

Host communication

CT input

Control output 1

Control output 2

15

Relay contact

NO

OUT1

Voltage pulse/

Current/

Voltage

OUT1

+

−

5

2

5

2

3

6

7

16

17

+

−

24 V

DC

Power supply

Ground

Thermocouple

TC1

+

−

Input channel 1

Voltage/

Current

IN1

+

−

RTD

RTD1

B

B

A

NO

OUT2

OUT2

+

−

4

1

4

1

10

13

10

14

13

13

10

TC2

+

−

IN2

+

−

9

12

8

12

12

9

RTD2

B

B

A

9

Input channel 2

19

18

20

FG

16 15 3

2

1

17

7

6

5

4

20 19 14 13 12

18 11 10 9

8

Upper-side terminal

CT2

Relay contact

Voltage pulse/

Current/

Voltage

Lower-side terminal

Thermocouple

RTD

Voltage/

Current

Voltage/

Current

For heat/cool PID control (V-TIO-H), Input channel 2

becomes unused.

For heat/cool PID control (V-TIO-H), Control output 1

corresponds to the heating output and Control

output 2 corresponds to the cooling output.

Mounting

dimensions

To prevent electric shock or instrument failure, do not

turn on the power until all the wiring is completed.

!

WARNING

5.9 mm or less

3.2 mm or more

Recommended tightening torque:

0.4

N

⋅

m (4 kgf

⋅

cm)