IMS01P12-E1

3

For Heat/Cool PID control (V-TIO-M), Input channel 2

becomes unused.

For Heat/Cool PID control (V-TIO-M), Control output 1

corresponds to the heating output and Control

output 2 corresponds to the cooling output.

Heater break alarm (HBA) function cannot be used

when control output is Voltage/Current output.

Control loop break alarm (LBA) function cannot be

used when control type is Heat/Cool PID control

(V-TIO-M).

If any of the products are missing, damaged, or if your

manual is incomplete, please contact RKC sales office

or the agent.

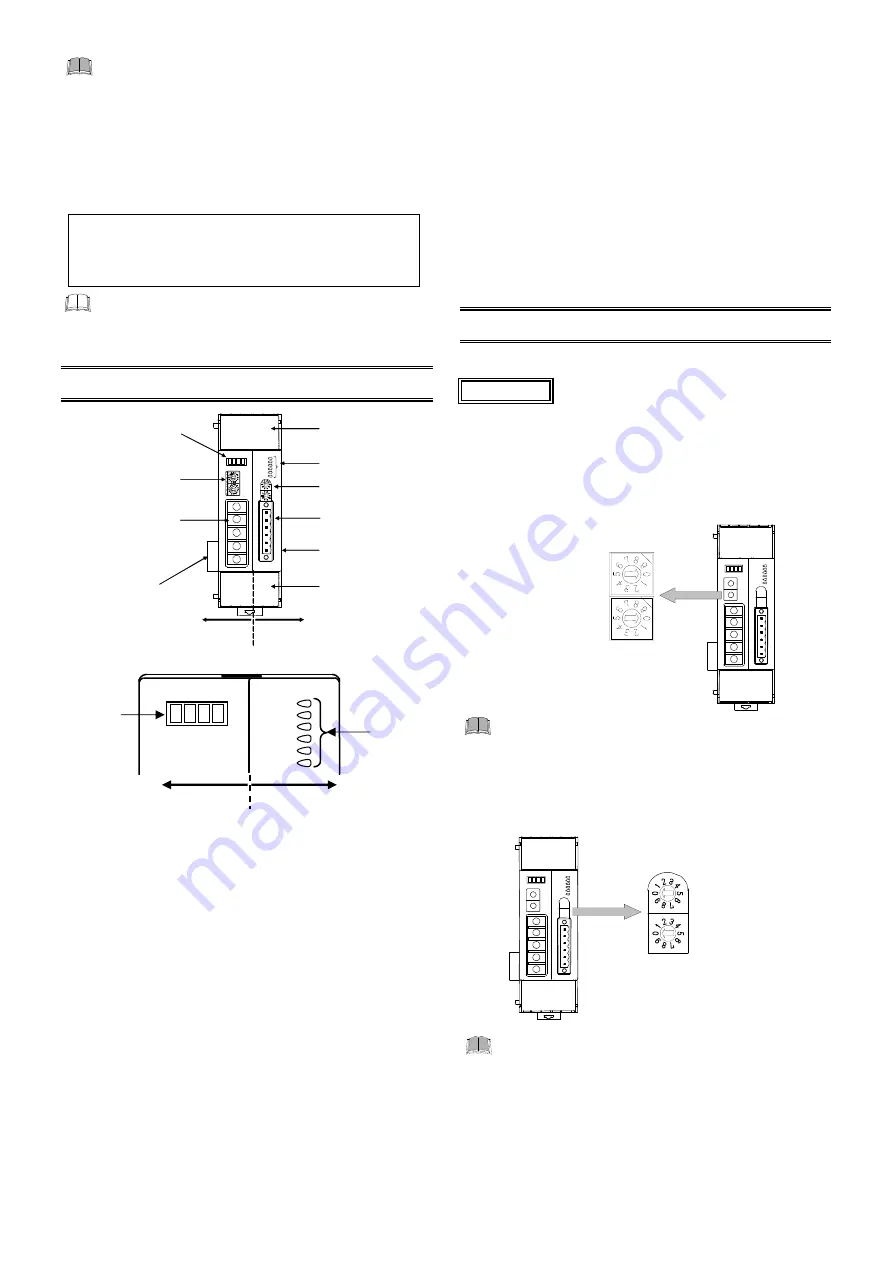

3. PARTS DESCRIPTION

FA

IL

RU

N

ON

L

TX

/R

X

FAIL/RUN

R X/TX

EVENT1

EVENT2

EVENT3

EVENT4

Terminal cover

Indication lamps 1

Module address

setting switch

Terminal cover

Joint connector

(Right-side)

Joint connector

(Left-side)

Indication lamps 2

Station number

setting switch

CC-Link connection

terminals

(COM.PORT)

CC-Link side

Temperature control side

Event input/output

connector

*

FAIL/RUN

RX/TX

EVENT1

EVENT2

EVENT3

EVENT4

FA

IL

RU

N

SD

RD

[Indication lamps 1]

FAIL/RUN (for temperature control side)

When normally:

A green lamp turns on (RUN)

When abnormally: A red lamp turns on (FAIL)

RX/TX (for host communication)

During data send and receive: A green lamp turns on

EVENT 1 to 4

Display various states by setting.

During ON state: A green lamp turns on

Display contents

Event 1 state, Event 2 state, Comprehensive event state, Output state,

and Control state

[Indication lamps 2]

FAIL (for CC-Link side)

When normally:

A red lamp turns off

When abnormally: A red lamp turns on

When station number, communication speed

setting abnormal

:

A red lamp turns on

In an station number, communication speed

setting change

:

A red lamp is flashing (0.4 seconds cycle)

When

CC-Link communication stopped/

internal

communication normal:

A red lamp is flashing (1 second cycle)

RUN

When normally (for internal communication):

A green lamp turns on

When abnormally (for internal communication):

A green lamp is flashing (0.5 seconds cycle)

In

validation of the module which it connected just after

the power is turned on

:

A green lamp is flashing (0.1 seconds cycle)

When

CC-Link communication stopped state:

A green lamp turns off

SD

During CC-Link data send:

A green lamp turns on

RD

During CC-Link data receive: A green lamp turns on

4. COMMUNICATION SETTING

Set communication setting before mounting and wiring of SRV.

Do not separate the module mainframe from the terminal

base with the power turned on. If so, instrument failure may

result.

4.1 Station Number Setting

Set a station number of CC-Link. For this setting, use a small

slotted screwdriver.

Setting range: 1 to 61

Factory set value: 0

Station number setting switch

High-order digit

setting

(Set value

10)

Low-order digit

setting

(Set value

1)

No communication with CC-Link can be conducted

with each factory set value (0) left as it is. Always set

the station number.

4.2 Module Address Setting

Set an address of module. For this setting, use a small slotted

screwdriver.

Module address setting switch

High-order digit

setting

(Set value

10)

Low-order digit

setting

(Set value

1)

Setting range: 0 to 30

Factory set value: 0

When setting module address, always set their

address from address number “0” in succession.

Otherwise, problems or malfunction may result.

For host communication (Modbus), the value

obtained by adding “1” to the set address

corresponds to the address used for the actual

program.

Set the module address such that it is different to

the other addresses on the same line. Otherwise,

problems or malfunction may result.

Indication

lamps 2

Indication

lamps 1

Temperature control side

CC-Link side

Accessories

End Plate ....................................................................... 2

Joint connector cover .................................................... 2

V-TIO-L/V-TIO-M Instruction Manual (IMS01P12-E1) ... 1

* Installed when provided with the event input/output (optional).

CAUTION