IMS01P12-E1

4

4.3 Number of Occupied Stations/

Extended Cyclic Setting

With the DIP switch 1 which there is on the left side of module,

select

Number of occupied station/Extended cyclic

, CC-Link/Host

communication and communication speed for internal communication

in CC-Link.

Internal communication is communication that

V-TIO-L/V-TIO-M

module conduct to other temperature

control modules in CC-Link.

Left side view (CC-Link side)

Dip switch 1

1 2 3 4 5 6 7 8

ON

1 2 3 4 5 6 7 8

ON

OFF

1

2

Internal communication speed

OFF OFF

38400 bps

ON OFF

9600

bps

OFF ON

19200

bps

ON ON

38400

bps

Factory set value: 38400 bps

3 4 5

Number of occupied stations/

Extended cyclic

OFF OFF OFF

4 stations occupied 1 time (8 CH assignment)

ON OFF OFF

4 stations occupied 1 time (16 CH assignment)

OFF ON OFF

4 stations occupied 2 times (16 CH assignment)

ON ON OFF

4 stations occupied 2 times (32 CH assignment)

OFF OFF ON

4 stations occupied 4 times (32 CH assignment)

ON OFF ON

4 stations occupied 4 times (62 CH assignment)

Factory set value: 4 stations occupied 1 time (8 CH assignment)

6

Host communication protocol (CC-Link side)

OFF RKC

communication

ON Modbus

Factory set value: RKC communication

7 CC-Link/Host

communication

selection

OFF CC-Link (Internal communication validity)

ON Host communication (Internal communication invalidity)

Factory set value: CC-Link (Internal communication validity)

Switch No. 8: OFF fixed (Do not change the factory

set values)

[Factory set value]

Internal communication speed: 38400 bps

Number of occupied stations/extension cyclic:

4 stations occupied 1 time (8 CH assignment)

Host communication: RKC communication

CC-Link/Host communication:

CC-Link (Internal communication validity)

4.4 CC-Link Communication Speed Setting

With the rotary switch which there is on the left side of module,

select communication speed for CC-Link. For this setting, use a

small slotted screwdriver.

Setting range: 0 to 4

(Factory set value: 0)

Communication speed

setting switch

Left side view (CC-Link side)

Communication speed and maximum transmitter distance

(maximum length of Network)

[Use CC-Link dedicated cable Ver.1.10]

Communication

speed setting

Communication

speed

Maximum

transmitter distance

0

156 kbps

1200 m

1

625 kbps

900 m

2

2.5 Mbps

400 m

3

5 Mbps

160 m

4

10 Mbps

100 m

4.5 Host Communication Setting

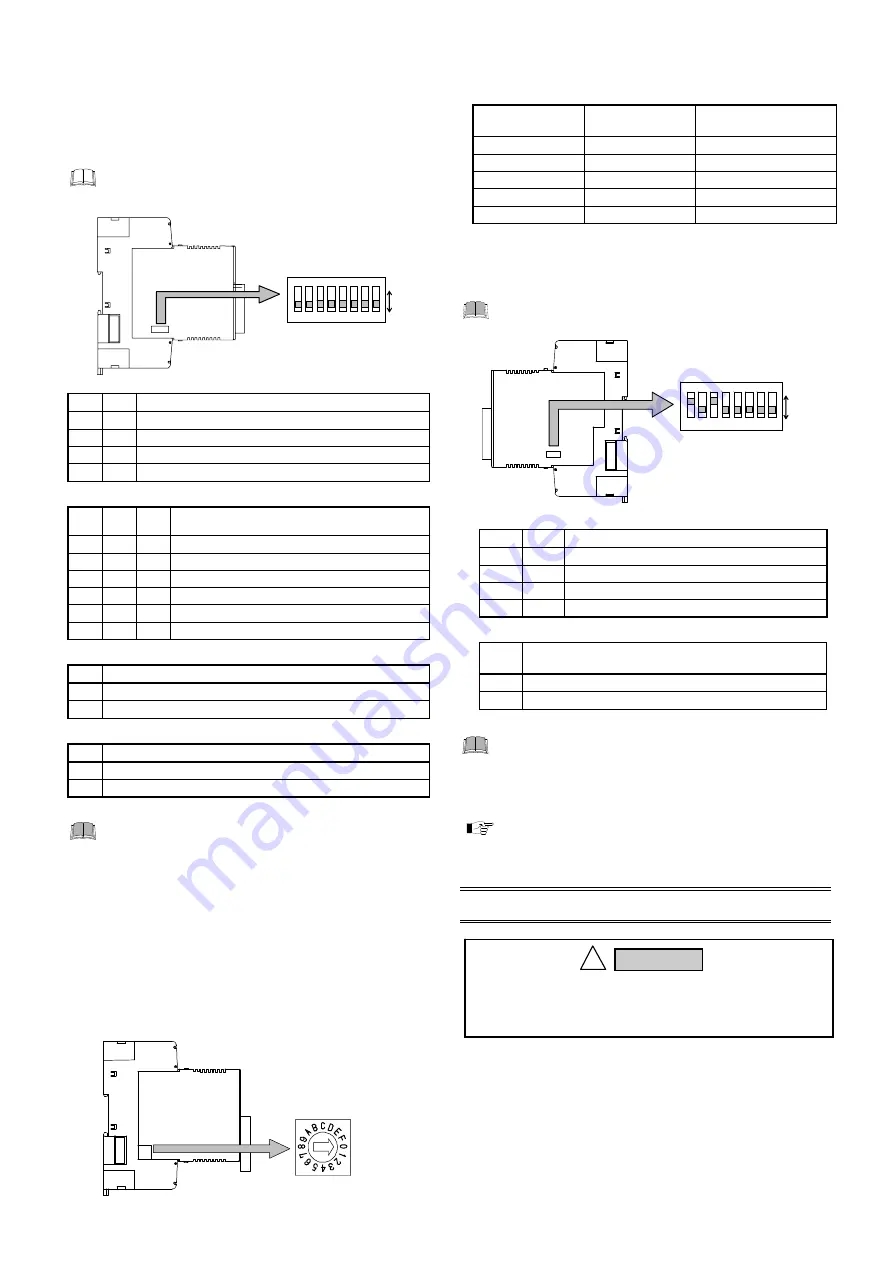

With the DIP switch 2 which there are on the right side of module,

select communication speed for host communication.

When host communication is not used, DIP switch 2

need not be set.

Right side view (temperature control side)

Dip switch 2

1 2 3 4 5

6

7

8

ON

1 2 3 4 5

6

7

8

ON

ON

OFF

1

2

Host communication speed

OFF

OFF

2400 bps

ON

OFF

9600 bps

OFF

ON

19200 bps

ON

ON

38400 bps

Factory set value: 9600 bps

6

Host communication protocol

(temperature control side)

OFF

RKC communication

ON

Modbus

Factory set value: RKC communication

Switch No. 3 to 5 and 7, 8: Do not change the factory

set values

[Factory set value]

Host communication speed:

9600 bps

Host communication protocol: RKC communication

For host communication, refer to the

Module Type

Controller SRV Communication Instruction Manual

(IMS01P01-E

)

.

5. MOUNTING

5.1 Mounting Cautions

(1) This instrument is intended to be used under the following

environmental conditions.

(IEC61010-1)

[OVERVOLTAGE CATEGORY II, POLLUTION DEGREE 2]

(2) Use this instrument within the following environment conditions:

Allowable ambient temperature:

10 to

50

C

Allowable ambient humidity:

5 to 95 %RH

(Absolute humidity: MAX. W. C 29 g/m

3

dry air at 101.3 kPa)

Installation environment conditions: Indoor use

Altitude up to 2000 m

To prevent electric shock or instrument failure, always

turn off the power before mounting or removing the

instrument.

!

WARNING