EAGLE 2 Operator’s Manual

Maintenance • 193

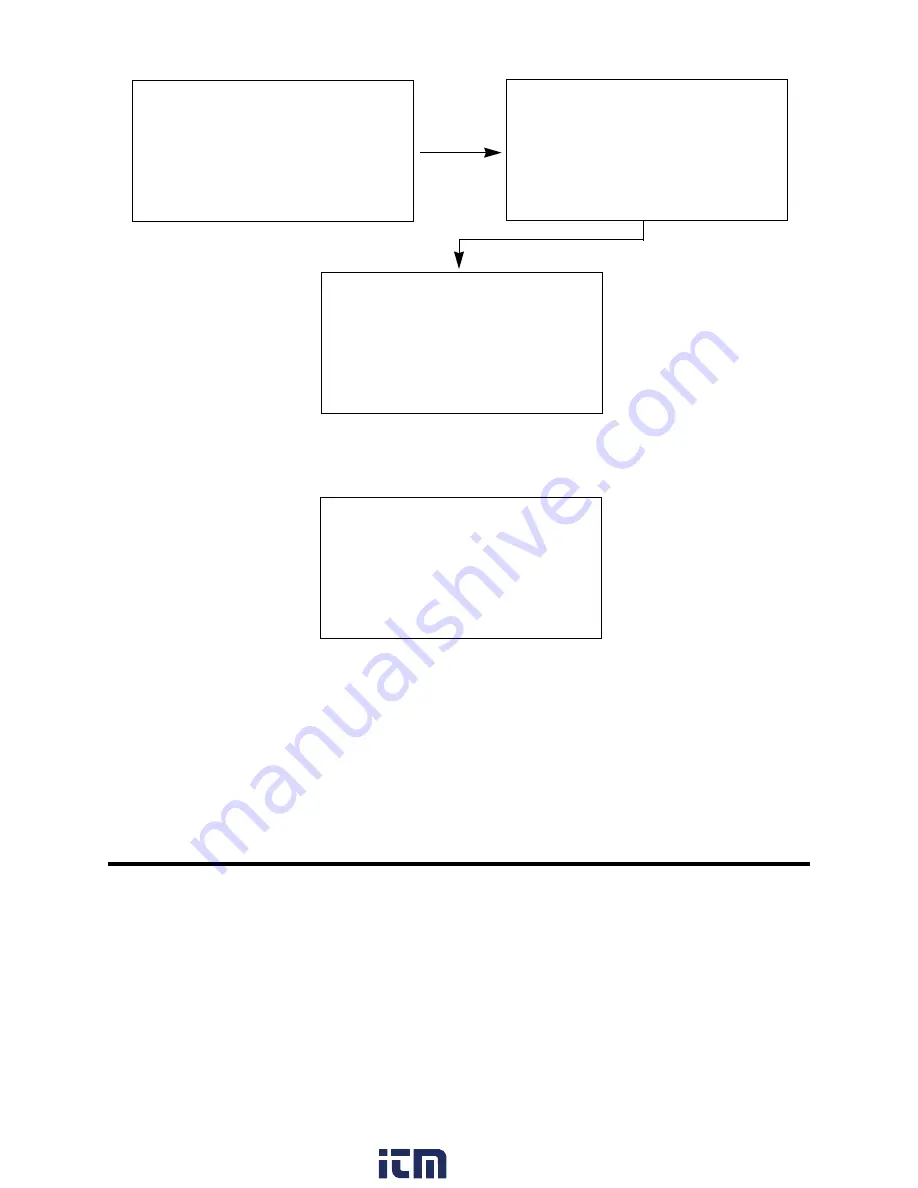

36. If the TC channel passed calibration, the following screen sequence occurs.

If the TC channel cannot be adjusted to the proper value, a screen displays that

indicates a calibration failure and indicates that the TC sensor failed to calibrate.

The buzzer and alarm LEDs activate in a double pulsing pattern. Press and release the

POWER ENTER RESET button to reset the alarm and continue to the Calibration

Mode Screen. Attempt to calibrate the TC channel again. If the failure continues,

investigate the cause. See “Troubleshooting” on page 67.

37. Disconnect the tubing from the probe.

38. Unscrew the demand flow regulator from the calibration cylinder.

39. Use the RANGE

▼

SHIFT button to place the cursor next to the

NORMAL

OPERATION

menu option, then press and release the POWER ENTER RESET

button to return to Measuring Mode.

Maintenance

The TC sensor does not include any user serviceable parts. This section includes a

procedure for replacing the TC sensor.

Replacing the TC Sensor

1. Verify that the EAGLE 2 is off.

2. Place the EAGLE 2 upside down on a flat surface or hold it upside down.

AUTO CALIBRATION

DONE

REMOVE GAS

AUTO CALIBRATION

END

CALIBRATION MODE

> AUTO CALIBRATION

SINGLE CALIBRATION

PERFORM AIR ADJUST

NORMAL OPERATION

FAILED SENSOR

ENTER TO CONTINUE

<CH4>

www.

.com

information@itm.com

1.800.561.8187