14 • Setting the Operational Parameters in Edit Mode

Setting the Operational Parameters

in Edit Mode

Once the hardware has been assembled, use Edit Mode to confirm or adjust the

bump test and calibration parameters before using the SDM-2009.

The bump test parameters define how long fresh air and calibration gas are applied to

an instrument during a bump test. They also define the tolerance used in determining

whether an instrument fails or passes a bump test and whether or not a calibration

automatically takes place if a bump test fails. The calibration parameters define how

long fresh air and calibration gas are applied to an instrument during a calibration.

The bump test and calibration parameters are saved in the SDM-2009’s memory. If a

parameter is changed with one particular instrument installed in the SDM-2009, the

change will be in effect for the bump test or calibration of any subsequent instruments

until the parameter is changed again.

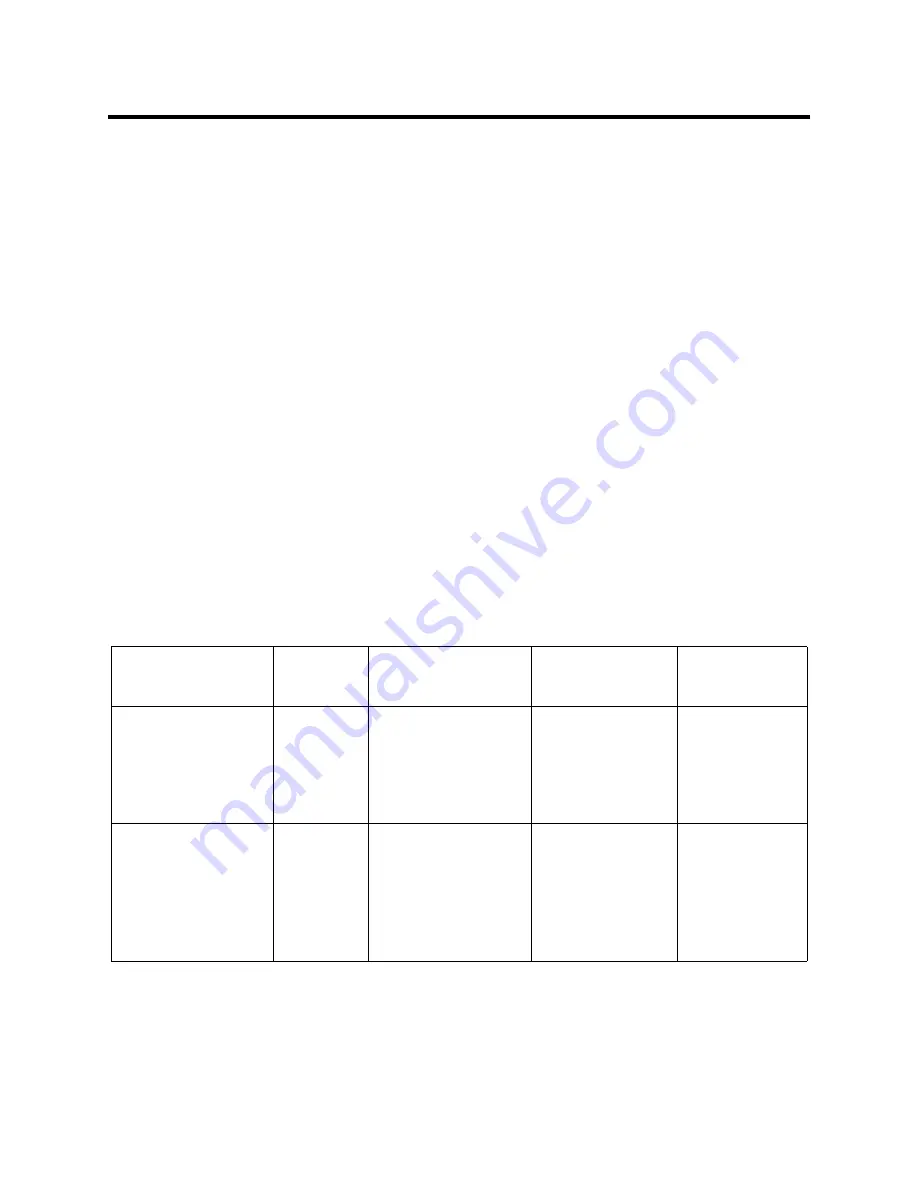

Bump Test & Calibration Parameters

There are four bump test parameters and two calibration parameters. The two

calibration parameters, air sample time and calibration gas sample time, are also

bump test parameters. The parameters are described below. Table 3 below shows

the factory settings for the bump test and calibration parameters. If you wish to use

the factory settings, then you do not need to make any parameter adjustments. If you

wish to confirm or change the parameter settings, follow the instructions below in

“Setting the Bump Test Parameters” on page 18 or “Setting the Calibration

Parameters” on page 20.

Table 3: Bump Test & Calibration Parameter

Parameter

Display

Tag

Available

Choices

Bump Factory

Setting

Cal Factory

Setting

Air Sample Time

AIr

• 15 seconds

• 30 seconds

• 45 seconds

• 60 seconds

• 90 seconds

15 seconds

45 seconds

Calibration Gas

Sample Time

GAS

• 20 seconds

• 30 seconds

• 45 seconds

• 60 seconds

• 90 seconds

• 120 seconds

20 seconds

90 seconds