18 • Setting the Operational Parameters in Edit Mode

Setting the Bump Test Parameters

Do the following to set the bump test parameters.

1. Turn on the SDM-2009 with an instrument and establish a connection between

them as described above in "Turning on the SDM-2009 with an Instrument".

The instrument will display the home screen.

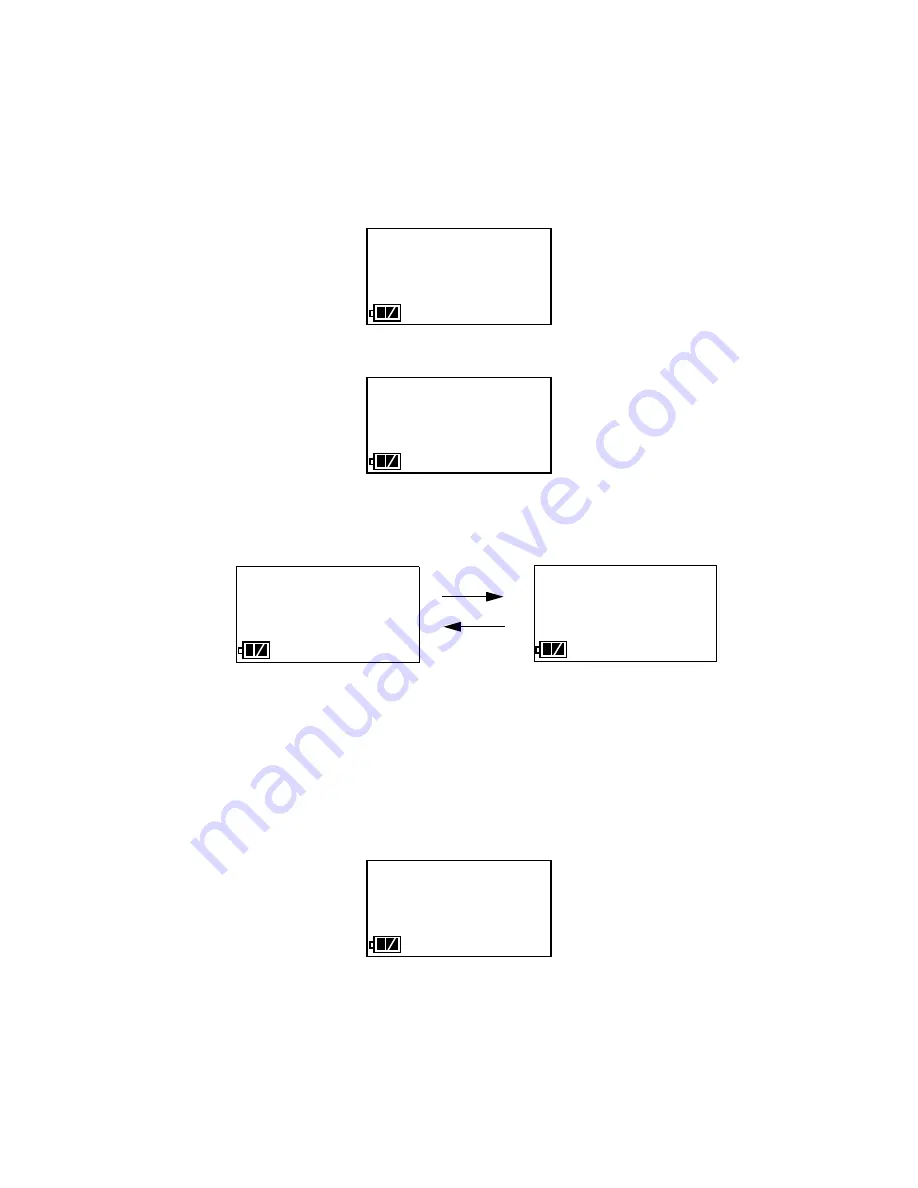

2. Press and hold the EDIT ENTER button for 2 seconds. The instrument will

display the Edit Mode screen.

3. Press and release the BUMP

button. The instrument will alternate between

the following screens that display the four bump test parameters and their

settings. The BUMP

LED will turn green.

4. If you wish to cancel setting the bump test parameters or were just viewing the

parameters to confirm their values, press and release the BUMP

button to

return to the home screen.

To continue and change parameters, press and release the EDIT ENTER

button. The Air Sample Time parameter will be displayed. For a description of

the Air Sample Time bump test parameter, see “Bump Test & Calibration

Parameters” on page 14.

50 12.0

TRANSMIT

CO ppm H2S ppm

CH4 %LEL OXY vol%

50 25.0

BUMP/CAL

AIr GAS

BUMP

CHE CAL

30 30

BUMP

50 O n

30

AIR--IN