49

Appendix

Operating manual neoTower® Premium L / 03.2017

1

6 In accordance with EU Regulation 811/2013; 813/2013

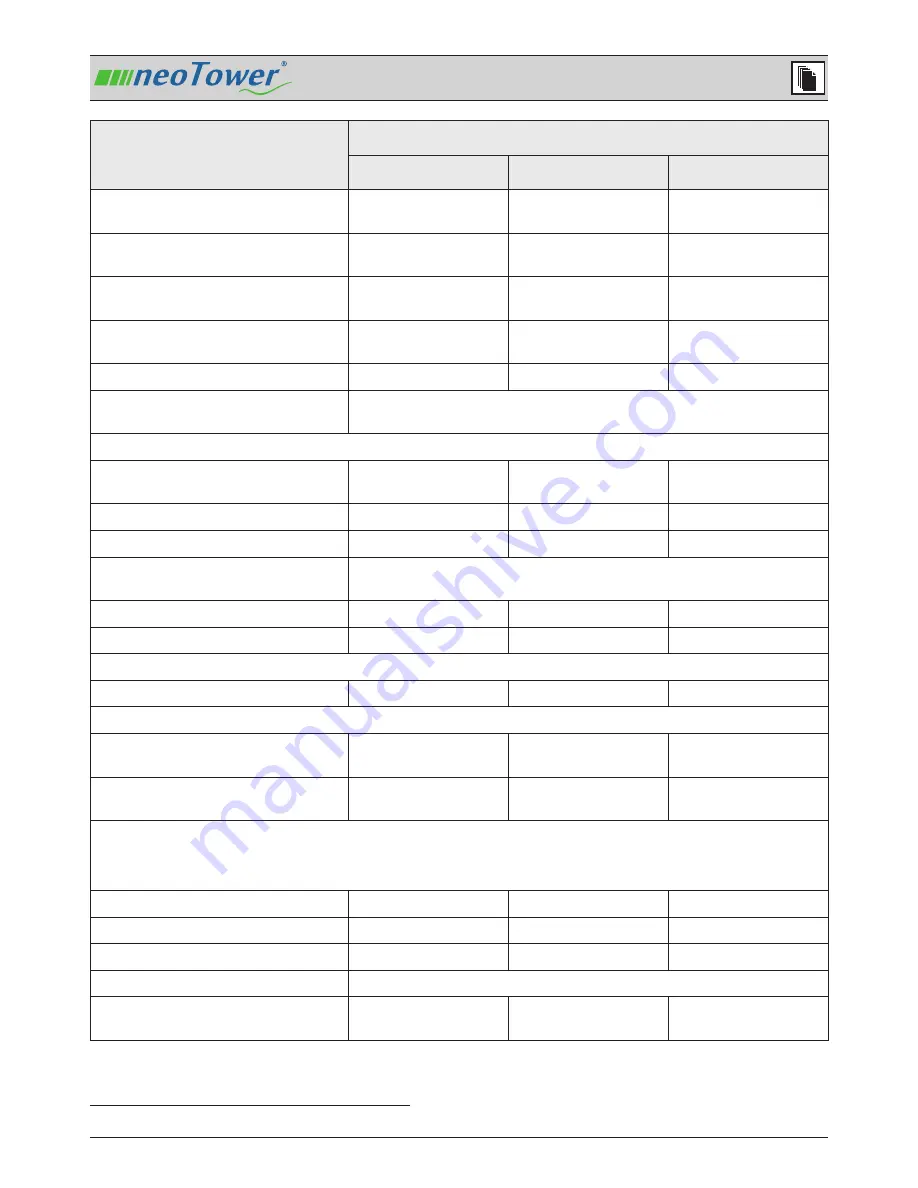

Product designation

neoTower® 50.0

Standard

High temperature

Calorific value

Electrical power requirement -

partial load

(6)

[kW]

0.7

0.7

0.7

P elmax Electrical power requirement -

full load

(6)

[kW]

0.7

0.7

0.7

P stby _CHP Thermal standing

losses

(6)

[kW]

0.9

0.9

0.9

Electrical power requirement -

standby

(6)

[kW]

0.1

0.1

0.1

ƞ

S =

ƞ

son -Σ(F1-F5)

(6)

155.5

155.5

155.5

12.4.12 Control cabinet

Fully equipped for seamless CHP unit operation with all necessary measurement and

control equipment in bivalent operation. Central heating controller provided

12.4.13 Electrical connections

Supply line to control cabinet

5 x 35 mm² Cu up to

max. 50 m

5 x 35 mm² Cu up to

max. 50 m

5 x 35 mm² Cu up to

max. 50 m

Prefuses

100 A slow blow

100 A slow blow

100 A slow blow

max. terminal area

50 mm²

50 mm²

50 mm²

Temperature sensor cable:

Temperature sensor cable: Min. 2-08 JY(ST)Y up to 15 m length

(2 x 1.5 mm² up to 40 m length)

Control cable pump

3 x 1.5 mm²

3 x 1.5 mm²

3 x 1.5 mm²

12.4.14 Reactive current compensation

synchronous

synchronous

synchronous

12.4.15 Gas standing pressure prior to controlled system [mbar]

Natural gas

23

23

23

12.4.16 Regulations and standards

Complies with the pertinent

EU Directives for CE certification

Yes

Yes

Yes

VDEW guidelines for the parallel operation

of decentralised power generation systems

Yes

Yes

Yes

12.4.17 Connections

Care must be taken to ensure that all connections are made using a flexible connector in order to guarantee vibration

damping.

Gas

3/4” male thread

3/4” male thread

3/4” male thread

Heating supply line

2” MALE THREAD / PN 2.5

2” MALE THREAD / PN 2.5

2” MALE THREAD / PN 2.5

Heating return line

2” MALE THREAD / PN 2.5

2” MALE THREAD / PN 2.5

2” MALE THREAD / PN 2.5

Flue gas

DN 80, thereafter DN 100

Exhaust air ᴓ (mm),

note the permissible counter-pressure!

200

200

200