Visit

www.rmspl.com.au

for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S25/Issue F/07/03/2011 - 3/9

COMBINED BUS BAR & SWITCHGEAR ARC PROTECTION

Figure 4 shows an application where a single 1S25 is applied for

the protection of a feeder Cable box & CT chamber plus the CB

chamber & BUS chamber using up to eight arc sensors over four

zones. In this configuration one arc trip output is used to trip the

feeder circuit breaker in the event of an arc fault in the cable box

/ CT chamber. Zone 2, 3 & 4 trip outputs are used to trip the BUS

breaker (BUS overcurrent check stage not shown), in the event of

an arc fault in the CB chamber or BUS chamber.

ZONE 1

ZONE 2

ARC PROTECTION

ZONE 3

ARC PROTECTION

ZONE 2, 3 & 4 TRIP

UP STREAM BREAKER

ZONE 4

ARC PROTECTION

COMMON ALARM OUTPUT

1S25

HEALTH Y

Z ONE 2

Z ONE 3

Z ONE 4

Z ONE 1

Cus tom te xt

Cus tom te xt

Cus tom te xt

Cus tom te xt

FAIL

FAIL

FAIL

FAIL

T RIP

T RIP

T RIP

T RIP

RESET

/T EST

50/51

Figure 4: Two arc sensors in zone 1 - Cable box & CT chamber

One or two arc sensors in zone 2 for CB chamber

One or two arc sensors in zone 3 for BUS chamber

One or two arc sensors in zone 4 for BUS chamber

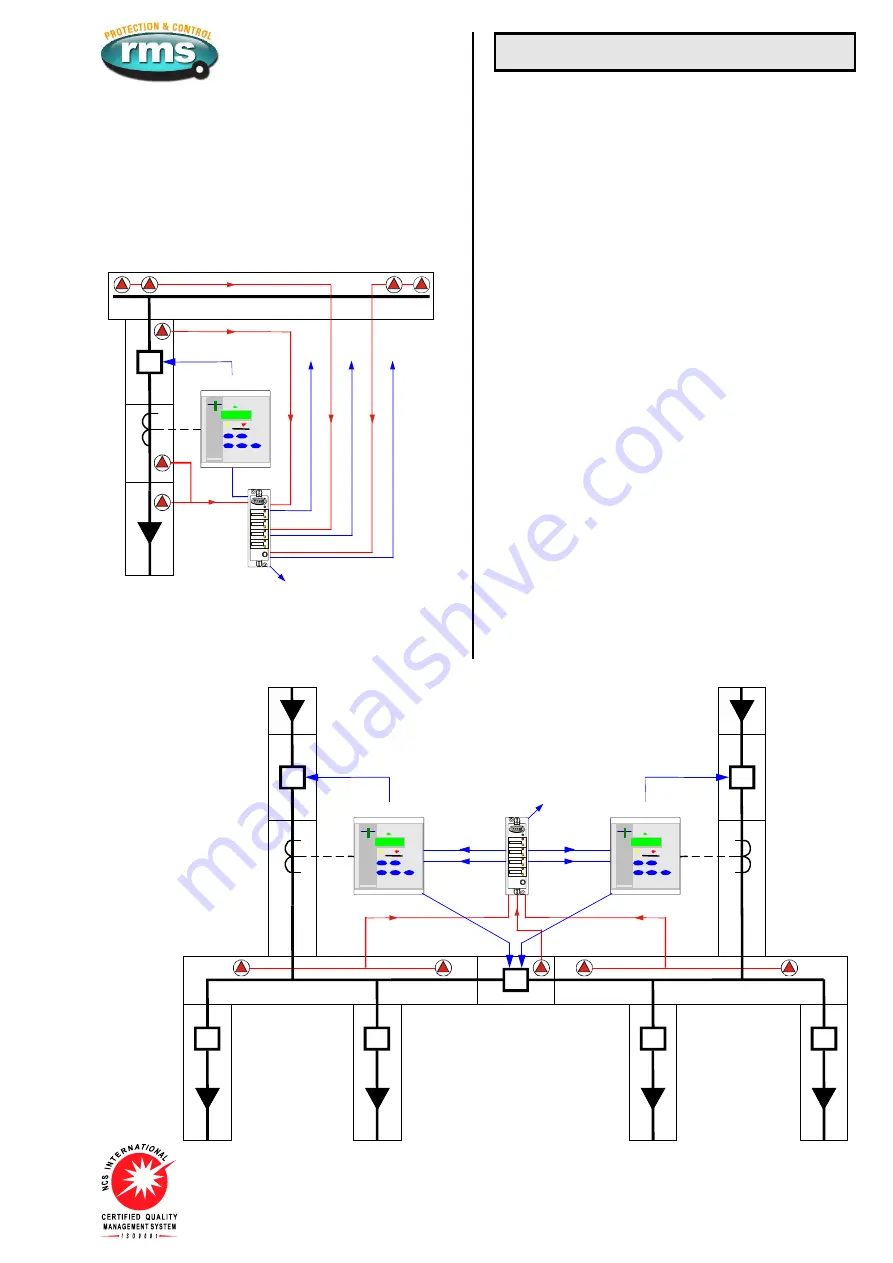

BUS Bar Applications

BUS BAR ARC PROTECTION

Figure 5 depicts how the 1S25 may also be applied for the

protection of bus bars. The number of sensors in the bus

chamber is dictated by the switchgear design and the length of

switchboard.

In most indoor metal clad switchgear the bus bar chamber is a

continuous chamber between panels only broken into segregated

sections at a bus section breaker & as such the strategic

placement of one or two arc sensors in each bus bar chamber

run is normally adequate.

Some indoor metal clad switchgear may segregate the bus

chamber of each panel from the next via insulated bus chamber

side barriers per panel, if this is the case then each bus chamber

per panel would need to be monitored by at least one arc sensor.

Isolating switches between BUS bar sections need also be

considered & appropriate tripping zones created to ensure

isolation of the faulted section.

In large enclosures the arc sensors should be placed at

approximately 5m intervals. 1S30 arc sensors are also available

with dual optical detectors to allow detection of arc in both

directions.

ZONE 1 & 3

TRIP

COMMON

ALARM

OUTPUT

50/51

1S25

HEALTH Y

Z ONE 2

Z ONE 3

Z ONE 4

Z ONE 1

Cus tom te xt

Cus tom te xt

Cus tom te xt

Cus tom te xt

FAIL

FAIL

FAIL

FAIL

T RIP

T RIP

T RIP

T RIP

RESET

/T EST

ZONE 2 & 3

TRIP

50/51

ZONE 1

TRIP

ZONE

3

TRIP

ZONE 2

TRIP

ZONE

3

TRIP

ZONE 1

ZONE 3

ZONE 2

ZONE

1

TRIP

ZONE

2

TRIP

Figure 5: One to eight arc sensors located in the BUS chamber in up to four tripping zones