Visit

www.rmspl.com.au

for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S25/Issue F/07/03/2011 - 5/9

OPERATION INDICATOR

Two (2) LED’s are provided for each tripping zone to provide the

following status indications:

Trip: Flashes for 2s on detection of arc fault in zone & then solid

Resets when front panel reset button pressed or voltage

pulse applied to remote status input.

Fail: Flashes to indicate failure of 1S30 Arc Fault Sensor in zone.

CONFIGURATION SWITCHES

Three banks (A, B & C), of four (4) configuration switches are

accessible to the user by first withdrawing the relay module from

the outer case.

CONFIGURATION SWITCH SETTINGS

The internal wiring label identifies the position of the following

switch functions as follows:

Switch

ON

OFF

A1

Zone 1 Arc sensor fitted

Zone 1 Arc sensor not fitted

A2

Zone 2 Arc sensor fitted

Zone 2 Arc sensor not fitted

A3

Zone 3 Arc sensor fitted

Zone 3 Arc sensor not fitted

A4

Zone 4 Arc sensor fitted

Zone 4 Arc sensor not fitted

Switch

ON

OFF

B1

Zone 1 – 2 Arc sensors

Zone 1 – 1 Arc sensor

B2

Zone 2 – 2 Arc sensors

Zone 2 – 1 Arc sensor

B3

Zone 3 – 2 Arc sensors

Zone 3 -1 Arc sensor

B4

Zone 4 – 2 Arc sensors

Zone 4 – 1 Arc sensor

Switch

ON

OFF

C1

Latching trip contacts

Self reset trip contacts

C2

Independent trip outputs

Common trip outputs

C3

Apply volts to BLOCK

Remove volts to BLOCK

C4

DC only status inputs

AC/DC status inputs

ARC SENSOR CIRCUIT SUPERVISION

The 1S30 Arc Sensor is the heart of the system & supervision of

circuit continuity is critical for correct operation. To monitor the

integrity of the wiring between the 1S30 arc sensor & 1S25 Arc

Monitor, a continuous 2mA supervision current flows between the

units.

The 1S25 alarm contact will drop out after a 1s time delay if it

fails to detect this current.

The failed zone will be indicated by the front panel ‘Sensor fail’

LED.

Operation

ARC SENSOR FUNCTION

The 1S30 is an optical sensor that responds to the flash of light

emitted during the incidence of an arcing fault. Onset of the light

flash & detection by the 1S30 occurs in a few ms.

When an arc is detected, the resistance presented by the 1S30

drops to a level where the current flow increases to approximately

20mA. This increased current flow is instantaneously detected by

the 1S25 & its trip output contacts closed. Refer to the 1S30

Technical Bulletin for further details.

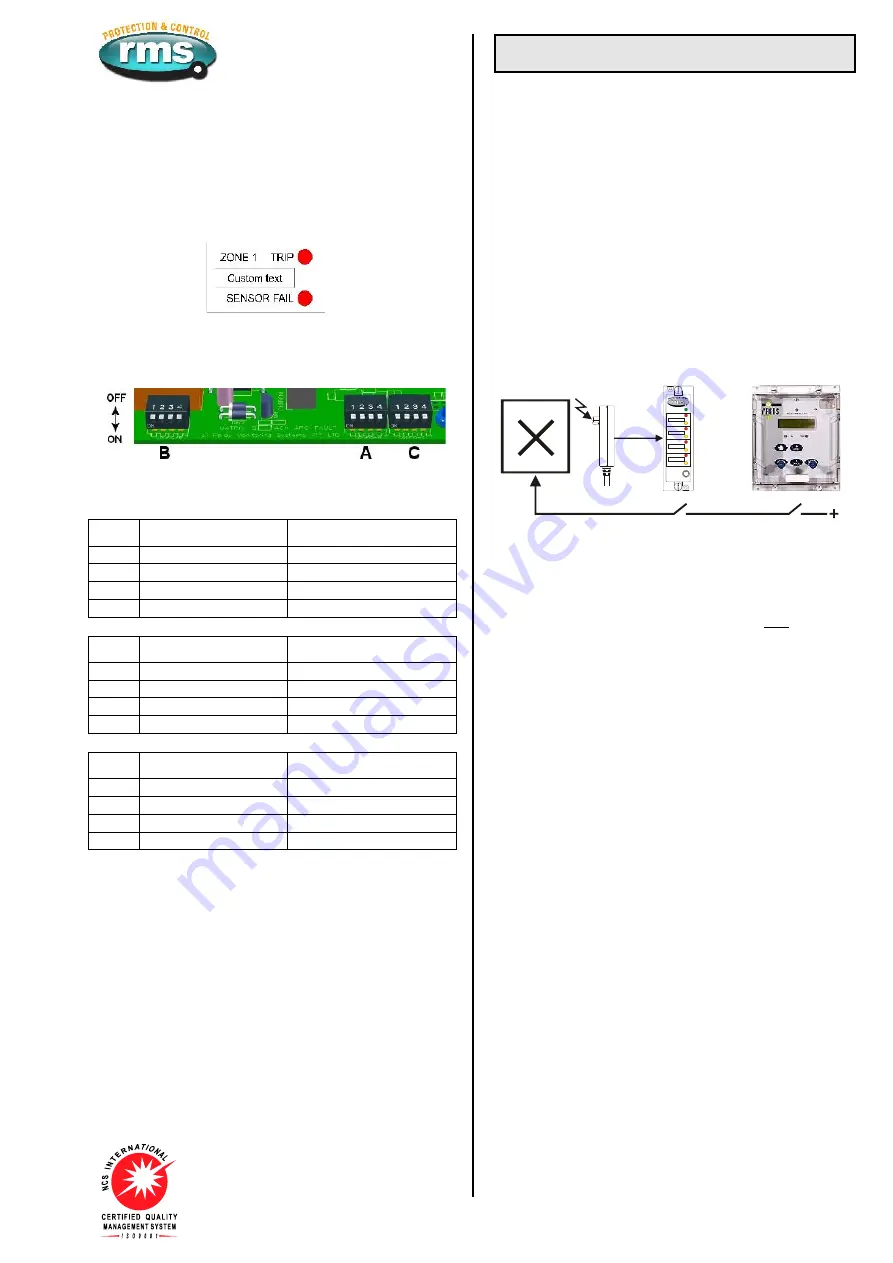

ARC FAULT TRIPPING USING CURRENT CHECK

Fast operation of a tripping scheme usually results in reduced

system security. The arc detection method can however,

combine the 1S25 optical detection technique with a traditional

overcurrent method to maximize system security particularly for

BUS bar protection schemes. Both conditions must coexist for

the trip condition to be met as depicted in figure 8.

ARC FAULT TRIP INITIATE

CB

ARC FAULT

MONITOR

SENSOR

OVER-CURRENT RELAY

3 Pole OC + EF

HEALTHY

ZONE 2

ZONE 3

ZONE 4

ZONE 1

Custom text

Custom text

Custom text

Custom text

FAIL

FAIL

FAIL

FAIL

TRIP

TRIP

TRIP

TRIP

RESET

/TEST

Figure 8:

Key components required to implement an Arc Fault Protection

scheme with an overcurrent check stage

to enhance system security

The application examples in figures 1 to 5 utilize this concept for

enhanced system security in that both the 1S25 AND the OC 50

starter contact must be picked up for a CB trip signal to be

initiated. As the arc fault trip contact picks up considerably faster

than the overcurrent relay starter element, the CB trip time will be

dictated by the overcurrent relay performance.

LOW CURRENT ARCING FAULTS

Arcing faults can occur at low current levels & it is possible for

the over-current starter element to be set above this level. To

avoid this problem & obtain very fast clearance (<10ms), of an

arc fault, the 1S25 arc fault trip contact may be wired directly to

the breaker operate coil. It should be noted that this method may

lead to reduced system security.

ARC DETECTION RESET TIME

(Effect of multiple arc trips)

A delay of 2s is required to reset the 1S25 after an initial arc

sensor trip. Subsequent arc detection will cause the trip output

contacts to re-operate.

INDEPENDENT TRIP OUTPUT CONTACTS

The 1S25 provides up to four (4) tripping zones each with an

independent tripping output. Alternatively configuration switch C2

can be set to OFF so that all trip outputs will operate in the event

of an arc being detected by any sensor.

ARC SENSOR CONTINUOSLY PICKED UP

High ambient light levels may cause a 1S30 to be continuously

picked up. This condition could occur for example if the CB cable

box cover was left open in very high ambient light level

conditions. A non arc fault over-current pick up would then result

in an arc fault trip operation.

To avoid possible mal operation due to this condition, the 1S25 is

designed to automatically disable the arc fault tripping function if

the 1S30 sensor is picked up for >10s. The 1S25 alarm contact

will be set & the front sensor fail LED will flash until the ambient

light level problem is corrected. The 1S25 will then perform an

arc sensor test function & automatically reset.

The failed zone will be indicated by the front panel ‘Sensor fail’

LED.