Visit

www.rmspl.com.au

for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S25/Issue F/07/03/2011 - 9/9

ALARM TEXT LABELS

The 1S25 front panel has provision for custom text to identify the

sensor location for each arc fault tripping zone. The required text

may be engraved on the front panel by the factory if specified at

time of order. Alternatively the front panel may be removed for

engraving by the user or contractor. The RMS web site provides

an ACAD file for this purpose.

The front panel is fabricated from flexible plastic sheet with a

white surface & black substrate to provide high contrast black

text when engraved.

Removal of the front label is achieved by drawing out the 1S25

module from the outer case & pulling the label from the edges at

the mid point between the top & bottom draw out handles. This

will cause the label to bend & disengage from the top & bottom

handle retention points. Once free from the 1S25 module the

front label can be placed on an engraving table. Additional factory

engraved labels may be sourced from RMS for later field

installation.

While an engraved label provides the most permanent record

other methods such as laser printed stick on labels or indelible

marker pen may be satisfactorily employed.

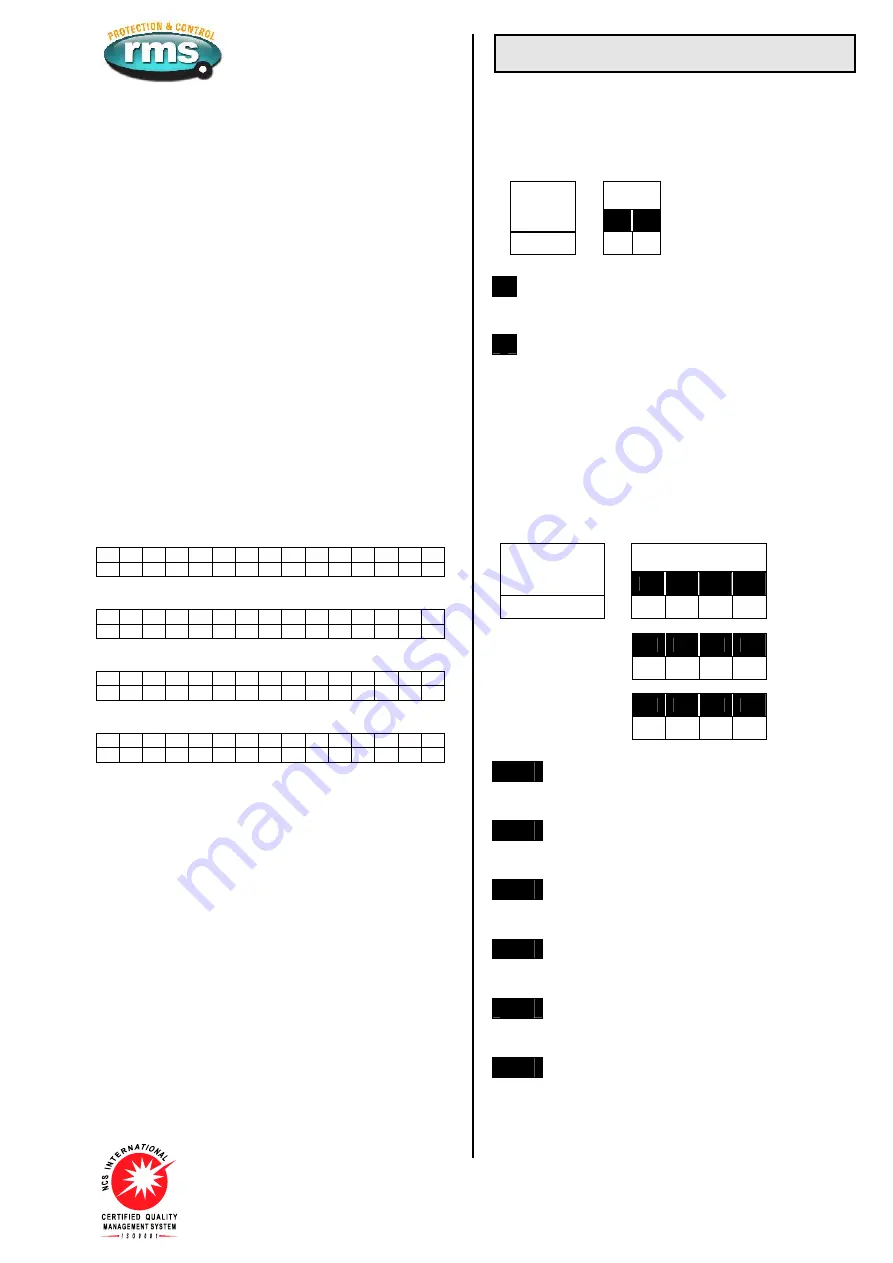

CUSTOM ENGRAVED TEXT DEFINITION

Complete the following tables with one character per box. Refer

to the front panel layout depicted in figure 10. Submit completed

labeling information with the 1S25 product ordering code. For

maximum font size limit text for each alarm point to 1 line x 10

characters.

Text will be left justified.

Zone 1

Zone 2

Zone 3

Zone 4

Ordering Information

ORDER CODE

The order code determines the production build in the factory &

cannot be changed in the field.

Generate the required order code as follows: e.g. 1S25 BA

Order

Code

General

Type

1

2

1S25

-

1

AUXILIARY SUPPLY RANGE

A

20 - 70V DC

B

40 - 300V DC & 40 – 275V AC

2

CUSTOM ENGRAVED TEXT

A

Not required No engraving - factory default

B

Required

Complete the custom text details at left

CONFIGURATION CODE

(Optional specification)

The configuration code can be set in the field by withdrawing the

relay module & following the instructions on the side plate label.

The configuration code may be specified at time of order so that

the relay will be shipped from the factory pre-set to meet

customer requirements. e.g. CONFIG-0101-0101-1111

If a configuration code is not specified the factory default will be

set as indicated below. i.e. CONFIG-1111-1111-1111

Configuration

Switches

Specify

Factory

Configuration

A1

A2

A3

A4

CONFIG

-

B1

B2

B3

B4

-

C1

C2

C3

C4

-

A1-4

ZONE 1 - 4 SENSOR INPUTS

1

ON

Arc sensor(s) connected

(Default)

0

OFF No sensor connected

B1-4

ZONE 1 - 4 SECOND SENSOR

1

ON

Second sensor connected

(Default)

0

OFF Single sensor only

C1

OUTPUT CONTACTS FUNCTION

1

ON

Latching

(Default)

0

OFF Self reset

C2

OUTPUT CONTACTS GROUPING

1

ON

Segregated zone tripping outputs

(Default)

0

OFF Common outputs

C3

ARC FAULT INITIATE INPUT FUNCTION

1

ON

Apply volts to BLOCK arc detection

(Default)

0

OFF Remove volts to BLOCK arc detection

C4

STATUS INPUT AC REJECTION

1

ON

DC operation only - AC rejection ON

(Default)

0

OFF AC / DC operation - AC rejection OFF