7

Please call our Customer Service Department at 800-577-4424 if we can be of

further assistance.

Battery.

The removable battery is located on top of the control

box. The battery should be charged daily.

Do not allow battery to

fully discharge, as this would shorten the life of the battery

.

Battery Cover.

The included nylon battery cover should be

placed over the battery to protect the components from the

elements.

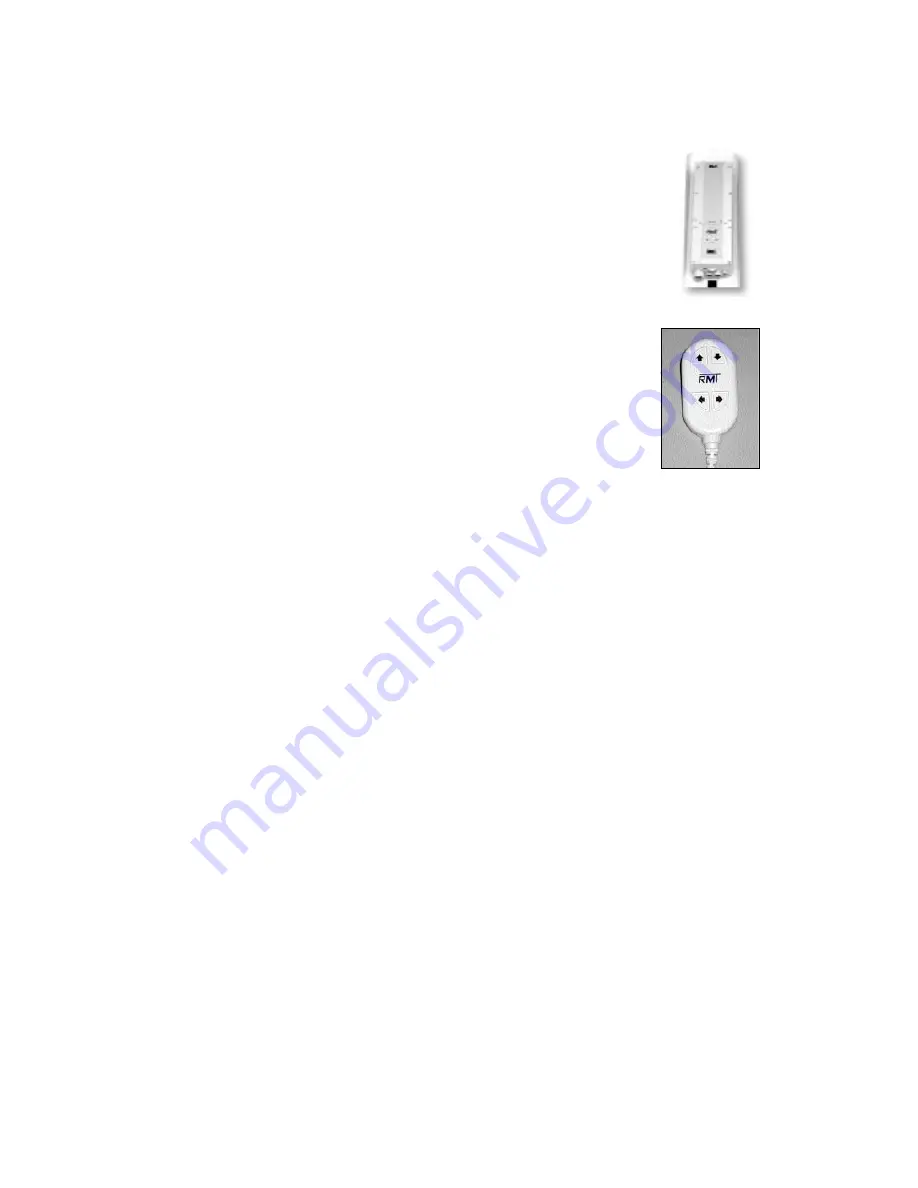

Hand Control.

Controls the actions of the lift. The two top

buttons control the lifting actions of the unit. The bottom pair of

buttons controls the side to side movement of the lift. The right

button turns the main mast to the right, and the left button turns

the main mast to the left.

Mast.

This vertical piece is bolted to the base assembly.

Actuator.

Attached to the top of the mast, this part powers the up and down

movements of the lift.

Rotation Motor Assembly.

Consists of mounting plate, 24-volt motor, and

small gear.

Hub Assembly.

Consists of hub, bearings, shaft, large gear and mast mounting plate.

Horizontal Support Arms.

These two support arms connect the mast to the

chair support arm. The longer horizontal support arm (actuator arm) connects to

the actuator and initiates the lifting movements.

Chair Support Arm.

Connects the chair to the horizontal support arms.

Seating System.

The seating system used with all RMT aquatic lifts is the

product of years of feedback from our customers and information gathered from

focus groups comprised of users of our lifts. Unlike most seats that are standard

“life guard type” plastic shells, this is the first such system that is designed

specifically for disabled swimmers.

The seat itself is both deeper and higher to both provide a more stable platform

for sitting, as well as being able to better accommodate swimmers with reduced

trunk stability. The seat has been flattened considerably to eliminate any ridge

that would hamper transferring. The sections of the seat have attachment points

for both the standard seat belt assembly as well as our optional stability vest. The

standard, molded plastic footrest is removable and will float upwards to prevent

damage if the user lowers the chair too low impacting the deck.