Rhein - Nadel Automation GmbH

2

Date: 14.04.2014

VT-BA-GL-GB

Contents

1

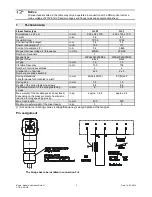

Technical data

Page 3

2

Safety instructions

Page 4

3

Construction and function of the linear feeder

Page 5

4

Transport and mounting

Page 5

5

Starting/Adjustment

Page 6

6

Specifications for the design of the track

Page 7

7

Maintenance

Page 8

8

Stockkeeping of spare parts and after-sales service

Page 8

9

What to do, if....?

Page 8

Instructions for trouble-shooting

Declaration of conformity

as defined by

Low voltage directive 2014/35/EU

Herewith we declare that the product complies with the following provisions:

Low voltage directive 2014/35/EU

applied harmonized standards:

DIN EN 60204 T1

remarks:

We assume that our product is to be integrated in a fixed machine.

Rhein-Nadel-Automation

--------------------------------

Managing Director

Jack Grevenstein