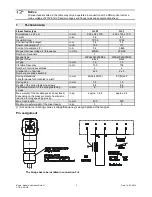

Rhein - Nadel Automation GmbH

5

Date: 14.04.2014

VT-BA-GL-GB

binding regulation for the qualification of electricians and personnel instructed in electrical engineering is

valid, as defined in IEC 364 and DIN VDE

0105 part 1.

Attention:

Since the electromaget-field may have an impact on persons arrying pacemakers it is

recommended to keep a minimum distance of 25 cm.

Noise emission

The noise level at the place of operation depends on the complete equipment and the material to be sorted. The

determination of the noise level according to the EC-Regulations "Machinery" can therefore only be carried out at

the place of operation.

If the noise level at the place of operation exceeds the limit permitted, noise protection hoods may be used, which

we offer as accessory parts (see catalogue).

Applicable Directives and Standards

The linearfeeder has been built in accordance with the following directives:

EC Low Voltage Directive 2014/35/EU

EMC Directive 2014/30/EU

We assume that our product will be integrated in a stationary machine. The user is to observe the regulations of the

EMC Directive.

Please refer to the Declaration of Incorporation for the applicable standards

.

3

Construction and function of the

linear feeder

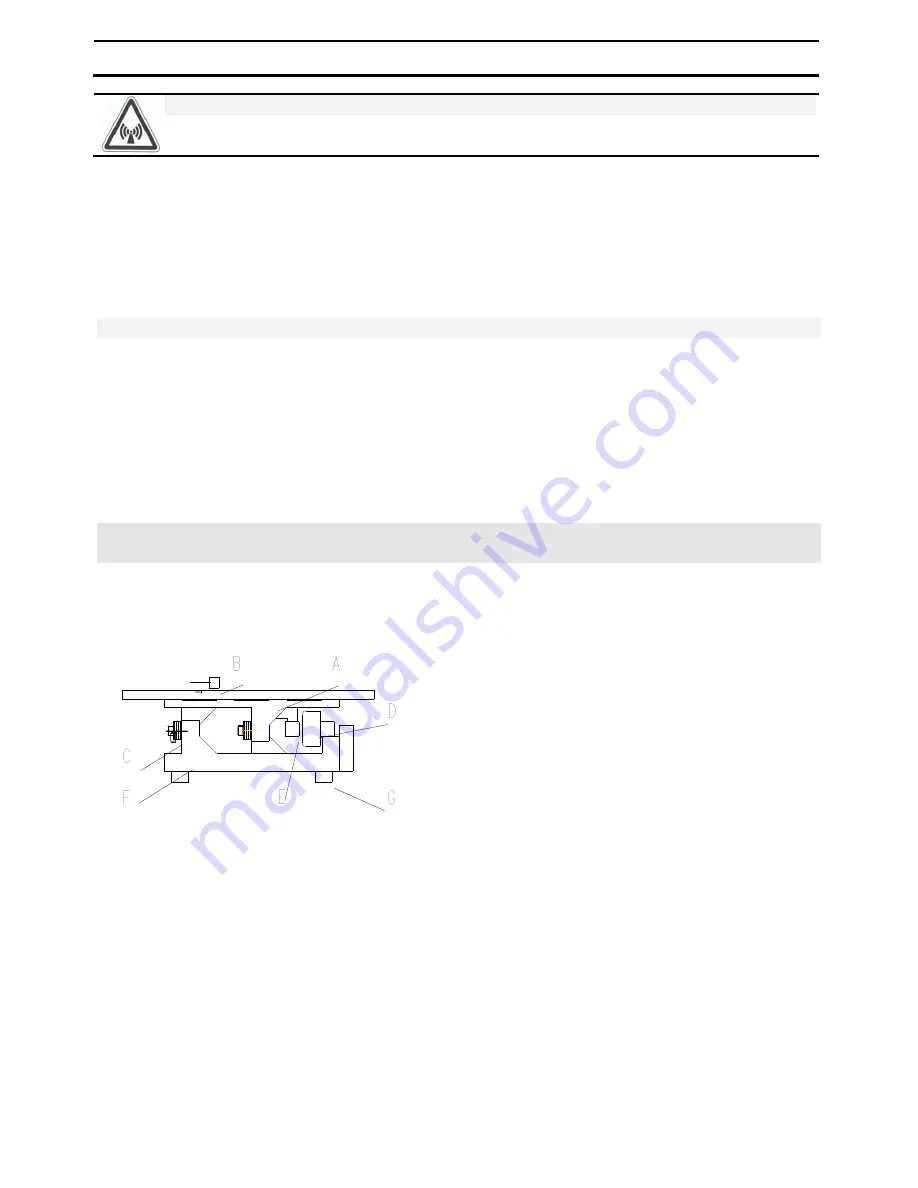

Linear feeders are used for the actuation of sorting machines. The actuation takes place by electromagnets. The

following schematic diagram shows the function of a linear feeder:

The linear feeder is a device of the familiy of vibratory bowl feeders. It is, however, equipped with a linear conveyor.

Electromagnetic vibrations are converted into mechanical vibrations and are used for conveying material B. When

the magnet D, which is fixedly connected with the counter-mass F, is supplied with current, it generates a power

that, dependent on the vibration frequency of the mains supply, attracts and releases armature E. Within a period

of the 50 Hz of the A.C. network the magnet achieves its maximum power of attraction twice, as this is independent

of the direction of the current conduction. The vibration frequency therefore is 100 Hz.

A linear feeder is a resonant system (spring-mass-system). The result is that the adjustment made at the plant will

rarely meet your requirements. Chapter 5 describes how your linear feeder is adapted to your requirements.

Controlling of the linear feeder takes place by a low loss electronic control unit type ESG 90. The control unit of the

linear feeder is separately delivered. At its front panel it is provided with a 5-pole plug-in connection, by which it is

connected to the linear feeder.

The pin assignment of the socket is shown in the table "technical data" (chapter 1).

A

Conveying track and oscillating weight

B

Material to be conveyed

C

Spring assembly

D

Drive magnet

E

Armature

F

Counter-mass

G

Vibration buffers