Rhein-Nadel Automation GmbH

10

VT-MA-STS-EN_2019 / 11.03.2019 SJ

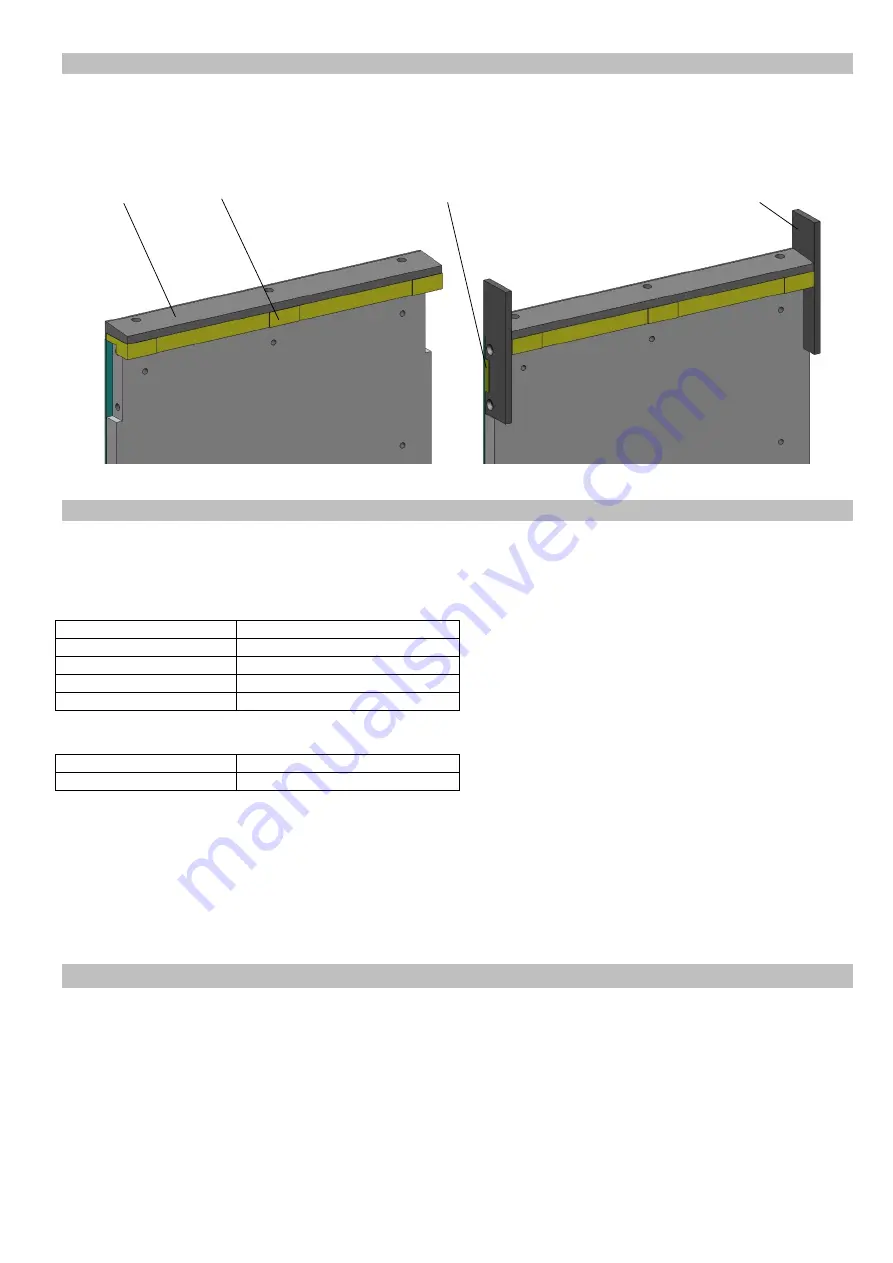

6.2. Replacing the sliding skids of step plates

To remove the sliding skids of the step plates dismount the step bar and lift out the skids. Step plates fitted with gap

blockers have additional lateral sliding skids in said blockers. To replace these sliding skids it is necessary to dismount

all step plates first. To do so, remove the front cover underneath the hopper of the step feeder. Now you can dismount

the step plates from bottom to top. For installation proceed from top to bottom. Take care to remount the screw locking

devices, if any.

Step bar

Sliding skid

Lateral sliding skids in gap blockers

Gap blocker

6.3. Linear guides of step frames

The linear guides of the step frames come with an initial charge of grease. The greases used are standard types such

as for antifriction bearings, with a base oil viscosity of 200 mm

2

/s at 40 °C. See table below for examples. Lubricants

containing MoS2 or graphite are prohibited.

Recommended greases for standard applications

HIWIN

G05

Klüber

MICROLUBE GL-261

Mobil

Mobilux EP1

Fuchs Lubritech

Lagermeister BF2

Lubcon

TURMOGREASE CAK 2502

Recommended lubricant charge for HIWIN HG_25 series

Initial lubrication

Relubrication

0.8 grammes (3x)

1.2 grammes

For initial lubrication, add the quantity of grease specified in the table by slow operation of the grease gun. Move the

runner block three times by a distance equalling approx. three times its length. Repeat the procedure described twice

more. Next move the runner block through its complete travelling distance and check that a film of lubricant is visible

on the complete rail. If not, add more lubricant.

If re-lubrication is required, dismount the covers on the side panels. In order to access the lubricating nipples (2 per

runner block) move the step frames until the runner blocks are in the area of the openings.

7.

Spare parts and customer service

For an overview of genuine spare parts available please refer to the separate spare parts list.

In order to make sure that your order is processed swiftly and correctly please specify the device type (see rating

plate), the quantity required, the spare part designation and the spare part number.

For a list of Service Center addresses refer to the back cover page of this manual.