Order Number

40 MHz No. F4044

FC-16 Boat `n Truck

15

20. SUB TRIM (SUB-TRIM/STRM)

When installing the servos in your

model, it always best to adjust linka-

ges so that the servo arms and its con-

trol are in their neutral (centre) position

when the Tx controls are neutral.

If you find that this is not possible or

your servos have another neutral posi-

tion, the Sub Trim function can be very

useful. This allows all 8 servos to be

adjusted to a new neutral position. This function is not designed

to act as a replacement for trimming the model in the traditional

sense.

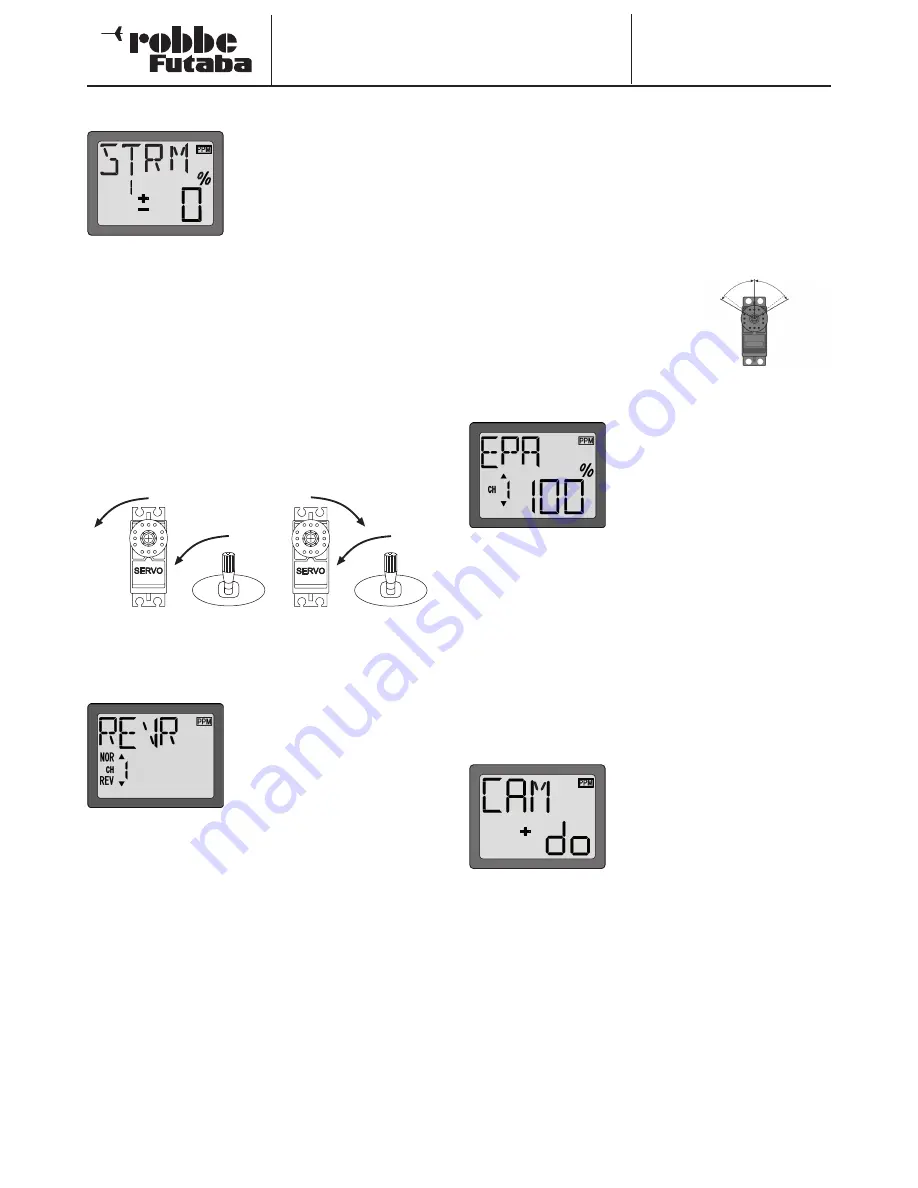

• Select with “MODE” key

• Select which channel from 1-8 you wish to STRM with the

CURSOR key

• Adjust the servo to its new neutral using “+” or “-“ key.

21. SERVO REVERSE (REVR)

This function will reverse the servo direction electronically. This

means you can install the servos in your model to give the most

direct linkage to the control without concern for servo sense of di-

rection. The servo direction can be reversed afterwards if needed.

Before further programming of the model takes place, we recom-

mend that you first correctly set the servo direction to suit your

model.

Select using “MODE” key after acti-

vating the programming mode.

The neighbouring display will be seen

to allow servo reverse to be made.

Select the channel for reversing with

the “CURSOR” key. Adjustments are

made using the “+” or “-“ key. If the (-)

key is depressed for more than half a

second, then the servo channel will be

set to “REVERSE” (REV). Pressing the (+) key will change the

setting to “NORMAL” (NOR) rotation. The arrow in the display

indicates the current rotation direction.

22. SERVO END POINT ADJUSTEMENT (EPA)

This function allows the end point to be set in each direction for all

channels. This can be adjusted from 40-140% of the total servo

travel including trim. This is to avoid stalling that servo against

a mechanical limit before it has reached its electronic limit. This

works on all servo channels and reduces all mixed functions. Ple-

ase note the trim amount is also proportional to the total servo

throw set.

The adjustment is made as a % age

value. Channels 1-8 have a 100 %

setting with approximately 40 de-

grees of servo rotation. With a servo

EPA of 120%, 55 degrees of servo

rotation will be available.

Select using “MODE” key to activate

EPA. The neighbouring display will

be seen. In the left half of the display,

you will see the channel number of the

servo to be adjusted. The right hand

side of the display has a flashing indi-

cation of the EPA value shown in %.

The relevant stick must be moved to select the direction for ad-

justment. Using the “+” or “-“ keys, the EPA value can be set. (-)

Reduces and (+) increases the value. Please note the servo throw

must be adjusted for both sides of neutral.

The “CURSOR” key chooses the channel for adjusting the servo

travel.

23. CAMPAC MODEL MEMORY INITIALISE

The Tx has 10 internal model memories. A further 10 memories

can be stored using a 16k CAMPac module. Remove the dust

cover and plug the CAMPac into the socket on the Tx front face.

NOTE: Before plugging in or removing

the module, the Tx must be turned off.

When a new CAMPac module is fitted

for the first time, it must be initialised

before use. After switching on the Tx,

“CAM “do” and CAM “-“ no will alter-

nate in the display. Press (+) key to

start the automatic memory initialise.

This process takes 2 minutes and will appear in the display. Pres-

sing the “-“ key will revert to the “normal” display and no further

keystrokes are necessary.

adjustement range 40 à

140%

servo throw

of 100%

servo throw

of 100%