Baustufe 9:

Zusammenbau Fahrerhaus, Tank

Pos.-Nr.

Bezeichnung

Maße (mm)

Anzahl

9.1

Tankhälfte mit Stutzen

1

9.2

Tankhälfte ohne Stutzen

1

9.3

Inbusschraube

M3 x 10

2

9.4

U-Scheibe

ø 3,2 innen

2

9.5

Sechskantmutter

M3

2

9.6

Fahrerhaus

1

9.7

Kotflügelsegment, rechts

1

9.8

Kotflügelsegment, links

1

9.9

Eckblende

2

9.10

Kühlergrill

1

9.11

Karosseriehalter vorn

1

9.12

Einpressmutter

M2,5

3

9.13

Karosseriehalter rechts

1

9.14

Karosseriehalter links

1

9.15

Stabantenne

ø 0,5 x 500

1

9.16

Antennen-Steckverbindung 1 n. e.

Vorbereitende Arbeiten

-

Tankhälften 9.1 und 9.2 verkleben, grundieren, lackieren

und trocknen lassen. Eckblenden 9.9 sowie Kühlergrill

9.10 grundieren, lackieren und trocknen lassen.

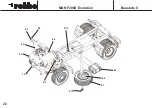

Montage Tank, Fahrerhaus (Pos. 9.1 - 9.16)

9a

Tank 9.1 - 9.2 mit Inbusschrauben 9.3, U-Scheiben 9.4

und Sechskantmuttern 9.5 am Leiterrahmen 1.1

verschrauben.

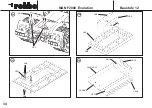

9b

Am Fahrerhaus 9.6 die Kotflügelsegmente 9.7 und 9.8

innen bündig ankleben.

-

Fahrerhaus grundieren, lackieren und trocknen lassen

-

Eckblenden 9.9 in das Fahrerhaus einstecken und

von innen verkleben.

-

Lack von den Klebeflächen entfernen, Kühlergrill 9.10

am Fahrerhaus ankleben!

9c

Position für den vorderen Karosseriehalter 9.11 gemäß

Abbildung im Fahrerhaus markieren. Einpressmutter

9.12 in den Karosseriehalter 9.11 eindrücken, mit

Sekundenkleber sichern und Halterung im Fahrerhaus

verkleben.

9d

Die hinteren Karosseriehalter 9.13 und 9.14 (mit

Einpressmuttern) fluchtend zur Kante „A“ verkleben.

Auf spaltfreien Sitz in den Ecken achten.

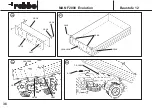

9e

Stabantenne 9.15 auf 450 mm ablängen, gemäß

Zeichnung 9f biegen und in das Fahrerhaus einschie-

ben.

9g

Litzenantenne des Empfängers um 450 mm

kürzen, abisolieren, Stecker der Antennen-

Steckverbindung 9.16 anlöten und Isolierung

aufschieben.

-

Buchse der Antennen-Steckverbindung 9.16 an das

Ende der Stabantenne 9.15 löten, Isolierung

aufschieben. Stabantenne im Fahrerhaus positionieren

und mit Zweikomponentenkleber verkleben.

-

Stabantenne mit Empfänger verbinden.

MAN F2000

Evolution

Baustufe 9

27

Stade 9: assemblage de la cabine, réservoir

n°

désignation

cotes (mm)

nbre

9.1

demi-réservoir avec raccords

1

9.2

demi-réservoir sans raccord

1

9.3

vis six pans creux

M3 x 10

2

9.4

rondelle

ø 3,2 intér.

2

9.5

écrou six pans

M3

2

9.6

cabine

1

9.7

segment d’aile, droit

1

9.8

segment d’aile, gauche

1

9.9

panneau angulaire

2

9.10

calandre

1

9.11

porte-carrosserie avant

1

9.12

écrou noyé

M2,5

3

9.13

porte-carrosserie, droit

1

9.14

porte-carrosserie, gauche

1

9.15

antenne rigide

ø 0,5 x 500

1

9.16

connecteur d’antenne

1 n.c.

Travaux préparatoires:

-

Coller, apprêter et peindre les parties 9.1 et 9.2 du réser-

voir et laisser sécher. Apprêter les panneaux angulaires

9.9 et la calandre 9.10 avant de le peindre et de les lais-

ser sécher.

Montage du réservoir, de la cabine (n° 9.1 à 9.16)

9a

Visser le réservoir 9.1-9.2 au châssis 1.1 avec les vis six

pans creux 9.3, les rondelles 9.4 et les écrous six pans

9.5.

9b

Coller à l’intérieur, à fleur de cabine 9.6 les segments

d’aile 9.7 et 9.8.

-

Apprêter, peindre et laisser sécher la cabine.

-

Planter les panneaux angulaires 9.9 dans la cabine et les

coller de l’intérieur.

-

Retirer la peinture des emplacements où est appliquée la

colle. Coller la calandre 9.10 sur la cabine.

9c

Selon les indications du schéma, marquer dans la cabine

la position des porte-carrosserie avant 9.11. Engager

l’écrou noyé 9.12 dans les porte-carrosserie, les y fixer

avec de la colle cyanoacrylate et coller le support dans la

cabine.

9d

Coller les porte-carrosserie arrière 9.13 et 9.14 (avec les

écrous noyés) en ligne avec l’arête „A“. Veiller à ce qu’ils

ne présentent pas de jour dans les coins.

9e

Raccourcir l’antenne rigide 9.15 de manière à ce qu’elle

mesure encore 450 mm, la couder selon les indications

du schéma 9f et la glisser dans la cabine.

9g

Raccourcir l’antenne souple du récepteur de 450 mm et

enfiler la gaine isolante. Souder le connecteur d’antenne

9.16 et mettre la gaine isolante en place.

-

Souder la douille du connecteur d’antenne 9.16 sur l’ex-

trémité de l’antenne rigide 9.15. Mettre la gaine isolante

en place. Positionner l’antenne rigide dans la cabine et

l’y coller avec une colle deux-composants. Raccorder

l’antenne rigide au récepteur.

Stage 9: assembling the driver’s cab, fueltank

Part No. Description Dimensions (mm)

No. off

9.1

Fueltank shell with stub

1

9.2

Fueltank shell without stub

1

9.3

Socket-head cap screw

M3 x 10

2

9.4

Washer

3.2 I.D.

2

9.5

Hexagon nut

M3

2

9.6

Driver’s cab

1

9.7

R.H. mudguard section

1

9.8

L.H. mudguard section

1

9.9

Corner fairing

2

9.10

Radiator grille

1

9.11

Front bodywork holder

1

9.12

Captive nut

M2.5

3

9.13

R.H. bodywork holder

1

9.14

L.H. bodywork holder

1

9.15

Whip aerial

0.5 Ø x 500

1

9.16

Aerial connector

1 N.I.

Preparation

-

Glue the fueltank shells 9.1 and 9.2 together, prime

and paint the tank, and allow to dry. Prime and paint

the corner fairings 9.9 and the radiator grille 9.10, and

allow them to dry.

Assembling the fueltank and driver’s cab (parts 9.1 -

9.16)

9a

Fix the fueltank 9.1 / 9.2 to the ladder frame 1.1 using

the socket-head cap screws 9.3, washers 9.4 and

hexagon nuts 9.5.

9b

Glue the mudguard sections 9.7 and 9.8 to the driver’s

cab; they should end flush on the inside.

-

Prime and paint the driver’s cab and allow it to dry.

-

Insert the corner fairings 9.9 in the driver’s cab and

secure them with a drop of glue on the inside.

-

Remove the paint from the joint surfaces before gluing!

Glue the radiator grille 9.10 to the driver’s cab.

9c

Mark the position of the front bodywork holder 9.11 in

the driver’s cab as shown in the illustration. Press the

captive nut 9.12 into the bodywork holder 9.11, secure

it with a drop of cyano and glue the holder in the dri-

ver’s cab.

9d

Glue the rear bodywork holders 9.13 and 9.14 (with

captive nuts) in place, flush with edge „A“. Check that

there are no gaps in the corners.

9e

Cut down the whip aerial 9.15 to a length of 450 mm,

bend it to shape as shown in drawing 9f and push it

into the driver’s cab.

9g

Cut down the flexible aerial attached to the receiver by

450 mm, and strip the insulation from the cut end.

Solder the plug of the aerial connector 9.18 to the bare

end and push the insulating sleeve into place.

-

Solder the socket of the aerial connector 9.16 to the

end of the whip aerial 9.15, push the insulator over it,

and install the whip aerial in the driver’s cab.

-

Connect the whip aerial to the receiver.