MAN F2000

Evolution

Baustufe 11

31

Baustufe 11:

RC-Einbau

Montage Fahrerhaus

Abschließende Arbeiten

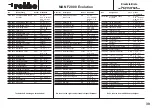

Pos.-Nr.

Bezeichnung

Maße (mm)

Anzahl

11.1

Doppelseitiges Klebeband

1 n. e.

11.2

Zylinderschraube

M2,5 x 30

1

11.3

U-Scheibe

ø 3,2 innen

1

11.4

Schlauchstück

ø 6 x10

1

11.5

Schraube

M2,5 x 14

2

11.6

Scheibenwischerblatt

3

11.7

Scheibenwischerarm

3

11.8

Spiegelhalter

ø 1,5 x 60

2

11.9

Rückspiegel-Vorderteil

11 x 23

2

11.10

Rückspiegel-Hinterteil

11 x 23

2

11.11

Rückspiegel-Vorderteil

10 x 13

1

11.12

Rückspiegel-Hinterteil

10 x 13

1

11.13

Spiegelhalterung

6 x 6

2

11.14

Bordsteinspiegel

10 x 15

1

11.15

Türgriff

2

11.16

Sonnenblende

1

11.17

Blechschraube

ø 1,3 x 4

2

-

Dekorbogen

1

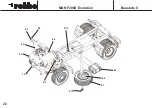

RC-Einbau (Pos. 11.1)

11a Lenkservo 2.19 und Fahrtregler 5.10 am Empfänger

7.1 anschließen.

11b Empfänger 7.1 mit doppelseitigem Klebeband 11.1

unter dem Cockpiteinsatz 10.2 befestigen.

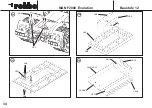

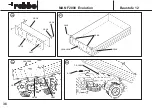

Montage Fahrerhaus (Pos. 11.2 - 11.5)

11c Zylinderschraube 11.2 mit U-Scheibe 11.3 durch die

noch freie Bohrung in Distanzstück 8.1 und

Stoßstange 8.14 stecken und Schlauchstück 11.4 bis

zum Anschlag auf die Schraube schieben.

11d Fahrerhaus 9.6 - 9.16 mit den Schrauben 11.5 an den

freien Bohrungen der Winkel 8.3 und 8.4 verschrau-

ben.

-

Fahrerhaus probeweise nach vorn klappen und

Schraube in Einpressmutter 9.12 eindrehen.

Nach dem Lösen der Verschraubung verhindert das

Schlauchstück das Herausfallen der Schraube.

Stage 11:

RC installation

Assembling the driver’s cab

Final work

Part No.

Description

Size (mm)

No. off

11.1

Double-sided foam tape

1 N.I.

11.2

Cheesehead screw

M2.5 x 30

1

11.3

Washer

3.2 I.D.

1

11.4

Hose

8 Ø x 10

1

11.5

Screw

M2.5 x 14

2

11.6

Windscreen wiper blade

3

11.7

Windscreen wiper arm

3

11.8

Mirror holder

1,5 Ø x 60

2

11.9

Rear-view mirror, front

11 x 23

2

11.10

Rear-view mirror, rear

11 x 23

2

11.11

Rear-view mirror, front

10 x 13

1

11.12

Rear-view mirror, rear

10 x 13

1

11.13

Mirror holder

6 x 6

2

11.14

Kerb mirror

10 x 15

1

11.15

Door handle

2

11.16

Sun visor

1

11.17

Self-tapping screw

1.3 Ø x 4

2

-

Decal sheet

1

RC installation (part 11.1)

11a Connect the steering servo 2.19 and the speed control

ler 5.10 to the receiver 7.1.

11b Fix the receiver 7.1 under the cockpit insert 10.2 using

double-sided foam tape 11.1.

Assembling the driver’s cab (parts 11.2 - 11.5)

11e Fit the washer 11.3 on the cheesehead screw 11.2,

and fit the screw through the remaining hole in the

spacer 8.1 and bumper 8.14. Push the short piece of

hose 11.4 onto the screw as far as it will go.

11d Fix the driver’s cab 9.6 - 9.16 to the vacant holes in

the brackets 8.3 and 8.4 using the screws 11.5.

-

Tip the driver’s cab down, and fit the screw in the cap-

tive nut 9.12. The piece of hose prevents the screw

falling out when you undo the screw.

Stade 11:

mise en place de l’ensemble de réception

Montage de la cabine

Travaux de finition

N°

désignation

cotes (mm)

nbre

11.1

double face

1 n.c.

11.2

vis cylindrique

M2,5 x 30

1

11.3

rondelle

Ø 3,2 intér.

1

11.4

morceau de flexible

Ø 6 x 10

1

11.5

vis

M2,5 x 14

2

11.6

balai d’essuie-glace

3

11.7

essuie-glace

3

11.8

support rétroviseur

ø 1,5 x 60

2

11.9

partie avant du rétroviseur 11 x 23

2

11.10

partie arrière du

11 x 23

2

rétroviseur

11.11

partie avant du rétroviseur 10 x 13

1

11.12

partie arrière du

10 x 13

1

rétroviseur

11.13

support de rétroviseur

6 x 6

2

11.14

rétroviseur de trottoir

10 x 15

1

11.15

poignée de porte

2

11.16

pare-soleil

1

11.17

vis autotaraudeuse

ø 1,3 x 4

2

-

autocollants de décoration

1

Mise en place de l’ensemble de réception (n° 11.1)

11a Raccorder le servo de direction 2.19 et le variateur de

vitesse 5.10 au récepteur 7.1.

11b Fixer le récepteur 7.1 avec du double face 11.1 au

dessous de l’habitacle 10.2.

Montage de la cabine (pos. 11.2 à 11.5)

11c Planter le vis cylindrique 11.2 avec la rondelle 11.3

dans l’alésage encore libre de l’entretoise 8.1 et le

pare-chocs 8.14 et glisser le flexible 11.4 en butée sur

la vis.

11d Visser la cabine 9.6 à 9.16 à l’aide des vis 11.5 dans

les alésages libres des équerres 8.3 et 8.4.

-

Rabattre la cabine pour essai vers l’avant et serrer la

vis dans l’écrou noyé 9.12. Après desserrage de la

fixation par vis le morceau de flexible empêche la

chute de la vis.