-

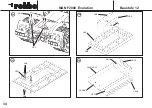

La nervure étroite de la plaque de renfort se trouve

systématiquement en bas.

-

Coller la plaque de tête 12.12 à la plaque de renfort

avant 12.13.

12e Lors du collage de la plaque arrière 12.14 à la plaque

de renfort 12.15 veiller à la coïncidence des alésages.

-

Visser les charnières 12.16 avec les vis 12.17 et les

écrous 12.16 à la plaque arrière.

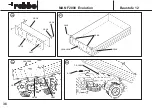

12f Coller la plaque de tête à l'avant à angle droit sur le

châssis/cuve de la benne.

-

Coller les montants latéraux à la cuve et à la plaque

de tête. Pour ce faire, maintenir la plaque arrière entre

les montants sans la coller toutefois.

-

Peindre maintenant la benne et la plaque arrière.

-

Monter la plaque arrière terminée entre les parois avec

les vis 12.19 et les écrous 12.20 de manière à ce

qu'elle soit en mesure de pivoter.

12g Visser un écrou autobloquant 12.21 sur la tige filetée

12.22.

-

Installer la benne terminée sur la châssis. Planter la

tige filetée dans les porte-palier et l'y fixer avec un

autre écrou autobloquant 12.21.

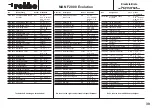

12h Amener le cordon de connexion du variateur hors de

la cabine, vers l'arrière.

-

Munir l'accu d'entraînement 7.2 de morceaux de ruban

adhésif double face 12.23 et l'installer dans le châssis

sans l'y presser pour l'instant. Descendre la benne en

positionnant l'accu entre les longerons. Presser l'accu

sur le châssis.

MAN F2000

Evolution

Baustufe 12

37

-

Note that the narrow lug on the reinforcing plates must

be at the bottom.

-

Glue the front panel 12.12 to the front reinforcing plate

12.13.

12e Glue the rear panel 12.14 to the reinforcing plate

12.15, checking that the holes line up correctly.

-

Attach the hinges 12.16 to the rear panel using the

screws 12.17 and nuts 12.18.

12f Glue the front panel assembly to the front of the frame

/ base plate; check that the parts are at right-angles.

-

Glue the side panels to the floor and the front panel.

Hold the rear panel between the rear end of the side

panels to set the correct spacing, but don’t glue it in

place.

-

The tipper body and rear panel can now be painted.

-

Mount the completed rear panel between the side

panels using the screws 12.19 and nuts 12.20; it must

be free to rotate.

12g Fit one self-locking nut 12.21 on the threaded rod

12.22.

-

Place the completed tipper body on the chassis, slip

the threaded rod through the brackets, and secure it

with the second self-locking nut 12.21.

12h Locate the battery lead attached to the speed control-

ler and route it out of the driver’s cab to the rear.

-

Apply a strip of double-sided foam tape12.23 to the

drive battery 7.2, and place it on the chassis without

pressing it down. Hinge the tipper body down, and

position the battery correctly between the longitudinal

members. Press the battery down onto the chassis in

this position.

-

Der schmale Steg der Verstärkungsplatte befindet sich

jeweils unten.

-

Die Kopfplatte 12.12 mit der vorderen

Verstärkungsplatte 12.13 verkleben.

12e Beim Verkleben der Heckplatte 12.14 mit der

Verstärkungsplatte 12.15 auf deckungsgleiche

Bohrungen achten.

-

Die Scharniere 12.16 mit den Schrauben 12.17 und

den Muttern 12.18 an der Heckplatte verschrauben.

12f Die Kopfplatte vorn rechtwinklig auf den

Rahmen/Muldenboden kleben.

-

Die Seitenplatten am Boden und der Kopfplatte verkle-

ben. Dabei die Heckplatte hinten zwischen die

Seitenplatten halten, ohne sie mitzuverkleben.

-

Mulde und Heckplatte jetzt lackieren.

-

Die fertige Heckplatte mit Schrauben 12.19 und

Muttern 12.20 zwischen den Seitenwänden drehbar

montieren.

12g Eine Stoppmutter 12.21 auf die Gewindestange 12.22

aufdrehen.

-

Die fertige Mulde auf das Chassis setzen.

Gewindestange durch die Lagerböcke stecken und mit

der zweiten Stoppmutter 12.21 sichern.

12h Das Akkuanschlußkabel des Fahrtreglers aus dem

Fahrerhaus nach hinten führen.

-

Den Fahrakku 7.2 mit einem Doppelklebebandstreifen

12.23 versehen und auf das Chassis legen, jedoch

noch nicht andrücken. Mulde herunterklappen, dabei

den Akku zwischen den Längstraversen positionieren.

Akku auf das Chassis drücken.