7

6. Controller operation

The fixtures are individually addressed on a data link and connected to the controller.The fixtures respond to

the DMX signal from the controller.

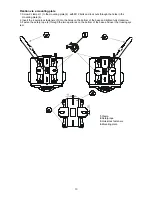

6.1 DMX addressing

The control panel on the front panel of the fixture allows you to assign the DMX fixture address, which is defined

as the first channel from which the ClubSpot 300 will respond to the controller.

If you set, for example, the address to channel 5, the ClubSpot 300 will use the channel 5 to 20 for control (if

16-bit mode is selected).

Please, be sure that you don’t have any overlapping channels in order to control each ClubSpot 300 correctly

and independently from any other fixture on the DMX data link.

If two, three or more ClubSpot 300 are addressed similarly, they will work similarly.

For address setting, please refer to the instructions under "Addressing"(menu "

A001"

).

Controlling:

After having addressed all ClubSpot 300 , you may now start operating these via your lighting controller.

Note:

After switching on, the ClubSpot 300 will automatically detect whether DMX 5 data is received or not.If

there is no data received at the DMX-input, the display will start to flash

"A001"

with actually set address.

This situation can occur if:

- the 3 PIN XLR plug (cable with DMX signal from controller) is not connected with the input of the ClubSpot

300

- the controller is switched off or defective, the cable or connector is defective or the signal wires are swap in

the input connector.

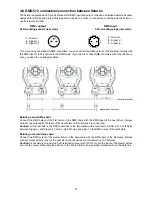

Note:

It’s necessary to insert the XLR termination plug (with 120 Ohm) to the last fixture in the link in order to

ensure proper transmission on the DMX data link.

6.2 Remotely controllable functions

Lamp

A relay inside of the ClubSpot 300 allows you to switch on and off the lamp via the control panel or via your

DMX-controller without affecting the rest of the lighting.

To switch On/Off the lamp, please refer to "Lamp On/Off " (menu

LAMP

).

Note:

It is also important to note, that the discharge lamp is cold restrike types, that means, that they have to be

cold before re-striking. For this reason, you have to wait 5 minutes (max. speed of fan must be adjusted) after

having switched Off the lamp before you can switch it back On again. If you try to switch On the lamp within 5

minutes after having switched it Off, the ClubSpot 300 will store this information and automatically ignite the

lamp when the 5 minutes period has expired. The message

"HEAt"

will appear on the control panel display of

the ClubSpot 300. If the ignition of the lamp is seven times unsuccessful, on the display will appear

"LA.Er"

,

meaning that the lamp could be damaged or even missed, or there could be a failure on the ignitor or ballast.

Colour wheel

The ClubSpot 300 CT features a colour-wheel with colour positions - of these with dichroic colors and

the last one open. The wheel can be positioned between two adjacent colors in any position. It is also possible

to rotate the color-wheel continuously at different speeds - the so-called „Rainbow effect“ is created.

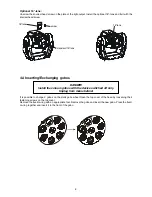

Gobo wheel

The rotating gobo-wheel includes 4 metal gobos, glass gobo and multicolour dichroic gobo rotating in

both directions, indexable, rotating gobo wheel cont. rotation slow to fast. The multicolour dichroic gobo can

be combined with the color-wheel especially with cyan, magenta and yellow colours in order to obtain several

different multicolour beams.

3-facet rotating prism

3-facet prism rotating in both directions at different speeds.

Focus

Motorized focus enables the beam to be focused anywhere on the stage.