6

7

Do not operate this fixture with open housing-cover!

4.2 Lamp adjustment

The ClubSpot 500 CT lamp holder is aligned at the factory. Due to differences between lamps, fine adjustment may im-

prove light performance.

Strike the lamp,open the shutter and set the dimmer intensity onto 100% and focus the light on a flat surface (wall). Center

a hot-spot(the brightest part of the image) by using the 3 adjustment screws

„A, B, C”

. Turn one screw after another a

quarter-turn clokwise(counter-clokwise) to set the hot-spot in the center of the image. If you cannot detect the hot-spot,

adjust the lamp until the light is evenly distributed.

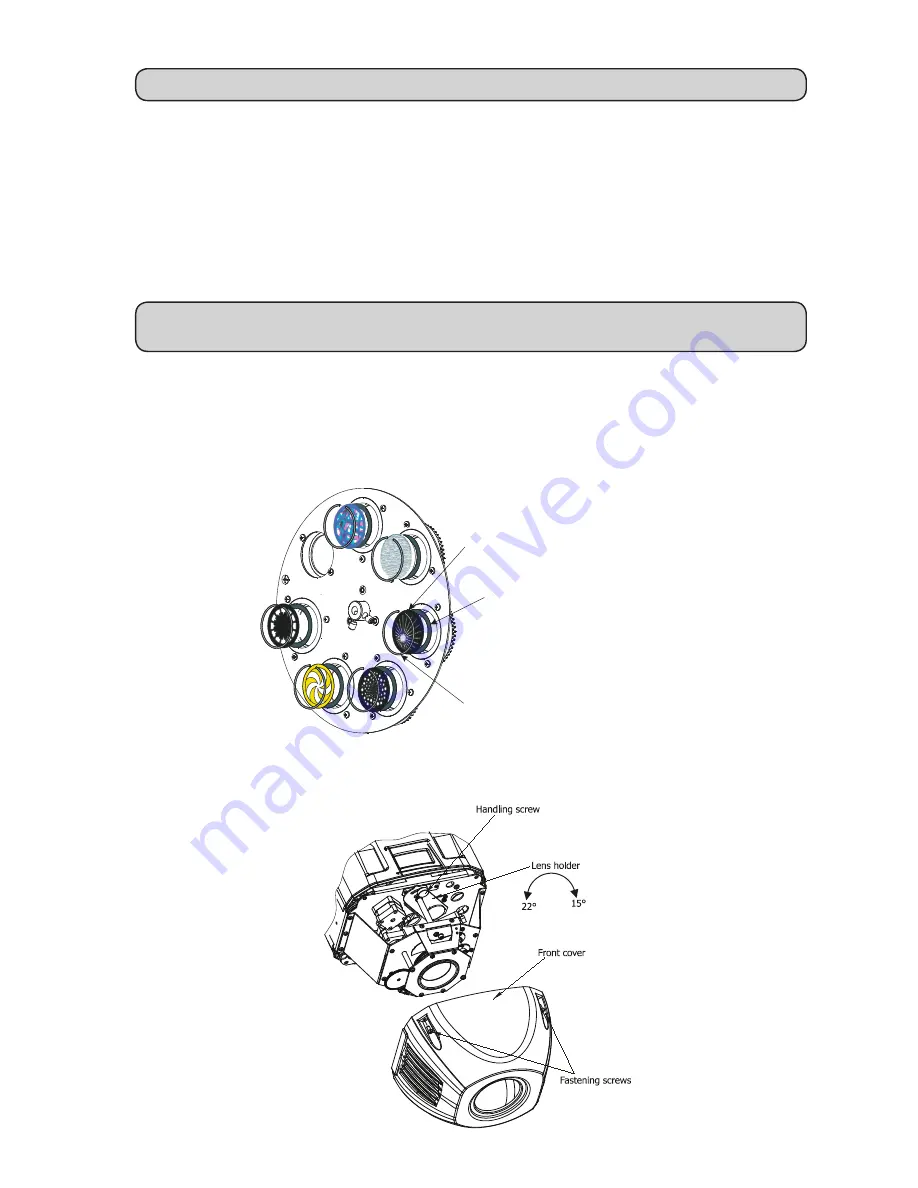

4.3 Inserting / Exchanging gobos

DANGER! Install the gobos with the device switched off only.

Unplug from mains before!

ITurn off the lamp and allow it to cool for at least 10 minutes. Disconnect the fixture from power.

Open the top cover of the moving head by loosening the 2 quarter-turn fasteners on the top cover and follow the instruc-

tions below:

1. Use an appropriate tool (e.g. screwdriver with narrow tip) to pull out the spring gobo-lock.

2. Caution remove the gobo and supporting ring from gobo holder.

3. Insert the supporting ring and the new gobo (black side towards the objective) back to the gobo holder.

4. Insert the spring gobo-lock into gobo holder to fasten the new gobo.

4.4 Manual zoom

The Clubspot 500 CT has manually adjustable zoom 15°or 22°.To change the zoom , remove the front cover by unscre-

wing the 4 fastening screws.Loosen the handling screw and move the lens holder into desired position as shown on the

picture below (lens inserted in beam path=22° angle).Tighten the handling screw to fix lens holder in desired position and

put the front cover back.

gobo

supporting ring

spring gobo-lock

Summary of Contents for clubspot 500 CT

Page 1: ...Version 1 1 ...

Page 2: ......

Page 24: ...24 Beampath Dimensions mm Weight net EU version 31 7 kg US version 35 6 kg ...

Page 26: ...26 ...