SECTION 5: D

UCT

H

EATER

I

NSTALLATION

7

SECTION 5: DUCT HEATER INSTALLATION

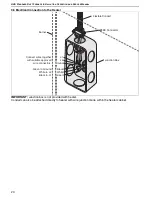

5.1 General

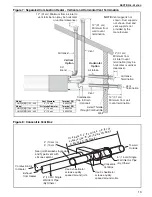

To connect the inlet and outlet ducts to the heater,

Duct-Mate or similar flanges may be slid over the

duct connector flanges supplied on the unit and

secured with screws. The connection to the duct

then can be made using the Duct-Mate clips. The

ducts must have removable access panels

upstream and downstream of the heater. These

panels must be of appropriate size and placement

so that smoke or reflected light could be observed to

indicate the presence of leaks in the heat

exchanger. Covers for these openings should be

sealed to prevent leakage.

Any transition into the inlet of the heater should be

smooth, with a taper of no more than 15°. If elbows

are required, they should be of either broad radius

or fitted with properly designed air turns. Consult a

professional to ensure air turns are properly

designed.

The heater must be installed on the positive

pressure side of the circulating air blower. Air flow

through the heater must be as shown

on Page 7,

Figure 2

and may not be reversed. The air flow must

be adjusted such that it is within the acceptable

range shown

on Page 7, Section 5.1.2

. The minimum

inlet duct lengths shown

on Page 7, Section 5.1.1

must be observed. Pressure drop through the heat

exchanger at various air flows is shown

on Page 7,

Section 5.1.2

.

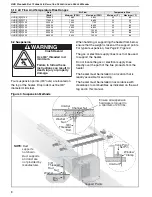

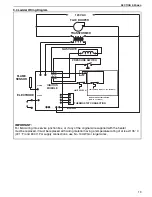

Figure 2: Air Flow Direction

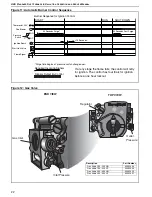

5.1.1 Minimum Inlet Duct Length

5.1.2 Temperature Rise and Pressure Drop Ranges

Model

Duct Length

Duct Size (W X H)

UHD[X][S][R] 150-175

52" (132 cm)

28" x 24" (71 cm x 60 cm)

UHD[X][S][R] 200-250

60" (162 cm)

28" x 32 1/4" (71 cm x 103 cm)

UHD[X][S][R] 300-400

75" (190 cm)

28" x 40 1/2" (71 cm x 82 cm)

UHD[X][S][R] 150

UHD[X][S][R] 175

UHD[X][S][R] 200

UHD[X][S][R] 225

Airflow

(CFM)

Temperature

Rise (°F)

Pressure

Drop

(in wc)

Airflow

(CFM)

Temperature

Rise (°F)

Pressure

Drop

(in wc)

Airflow

(CFM)

Temperature

Rise (°F)

Pressure

Drop

(in wc)

Airflow

(CFM)

Temperature

Rise (°F)

Pressure

Drop

(in wc)

1,360

83

0.02

1,400

95

0.03

2,050

73

0.025

2,100

80

0.035

1,950

58

0.035

2,180

62

0.06

2,600

58

0.035

2,800

61

0.052

2,800

41

0.057

3,244

42

0.10

3,600

42

0.056

4,600

37

0.110

3,700

31

0.083

4,370

31

0.15

5,500

28

0.100

6,230

27

0.167

4,700

24

0.12

5,160

27

0.19

6,570

23.5

0.129

7,400

23

0.214

5,800

20

0.16

6,850

20

0.29

7,750

20

0.163

8,300

20

0.253

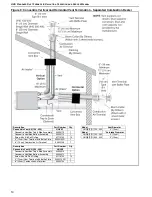

UHD[X][S][R] 250

UHD[X][S][R] 300

UHD[X][S][R] 350

UHD[X][S][R] 400

Airflow

(CFM)

Temperature

Rise (°F)

Pressure

Drop

(in wc)

Airflow

(CFM)

Temperature

Rise (°F)

Pressure

Drop

(in wc)

Airflow

(CFM)

Temperature

Rise (°F)

Pressure

Drop

(in wc)

Airflow

(CFM)

Temperature

Rise (°F)

Pressure

Drop

(in wc)

2,350

80

0.05

2,700

23

0.02

3,120

86

0.03

3,420

86

0.04

3,000

63

0.07

4,735

50

0.06

4,880

56

0.07

5,200

57

0.08

4,400

43

0.13

6,813

35

0.12

6,612

41

0.123

6,700

45

0.13

5,900

32

0.19

8,000

30

0.17

9,140

30

0.23

8,850

34

0.21

7,625

25

0.28

9,300

26

0.22

10,500

26

0.30

11,600

26

0.36

8,850

22

0.35

10,200

86

0.27

13,600

22

0.48

14,200

22

0.53