UHD L

OW

P

ROFILE

D

UCT

F

URNACE

I

NSTALLATION

O

PERATION

AND

S

ERVICE

M

ANUAL

38 of 47

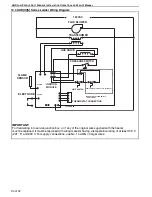

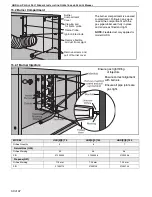

14.4 Troubleshootin

g

for Gas Valves

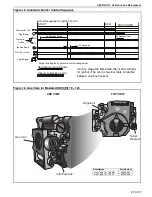

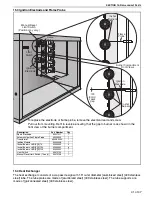

14.5 Troubleshootin

g

for Flue Blower

For optim

u

m heater performance,

u

se only replacement parts sold and s

u

pplied by Roberts-Gordon

LLC.

Conduct start-up procedure as shown

on Page 26,

S

ec

t

ion 11

.

Summary of Contents for Combat UHDXS 100

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 29: ...SECTION 9 GAS PIPING 21 of 47 Figure 14 Gas Connection ...

Page 43: ...SECTION 14 TROUBLESHOOTING 35 of 47 14 1 General ...

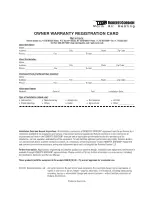

Page 54: ...UHD LOW PROFILE DUCT FURNACE INSTALLATION OPERATION AND SERVICE MANUAL 46 of 47 ...

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......