SECTION 13: S

TARTING

T

HE

S

YSTEM

49

SECTION 13: STARTING THE SYSTEM

Start with the main gas valve closed and the electric

power off.

13.1 Checking the Gas Line

1. Open the main valve and verify that no gas is

flowing through the meter.

2. Purge the line if this was not done following

pressure testing with air.

3. Verify that the gas pressure is not above

14'' w.c. (1/2 PSIG).

4. Close the main gas valve.

13.2 Checking the Electrical System

1. See that all temperature setpoints are set below

room temperature.

2. Turn on power supply to system controls.

3. Check to see that no part of the system (i.e.

burners, pump or air supply blower) is powered.

4. Individually check each zone by raising the zone

temperature set points separately. Raising each

zone temperature set point above room

temperature should start the pump immediately.

After a 45 second delay, the burners will begin

their ignition sequence by sparking at the

electrode (visible through the burner window).

5. Make a preliminary vacuum check at burners in

branches that have an adjustable damper

coupling.

See Page 50, Figure 35

for manome-

ter hookup to check vacuum. This check is to

insure that all dampers are open before the

system is fired. Vacuum, as measured at the

end vents, should be approximately 3.5'' w.c. or

slightly above (cold).

13.3 Starting the System

NOTE:

During the initial firing, the protective oil on

the tubing may smoke for 30 to 60 minutes and

adequate ventilation should be provided.

1. Start with all temperature setpoints below room

temperature.

2. Open main gas valve.

3. Turn up temperature setpoints one zone at a

time, waiting to see that all burners in a zone

start. When the burner ignites, a blue flame will

be observed through the viewer window.

4. If any abnormal operation occurs, see the trou-

bleshooting section of the service instructions.

13.4 Setting the Vacuum

1. Set temperature setpoints above room tempera-

ture. See that all burners are operating properly.

2. Allow at least ½ hour operation for temperature

to normalize, then check system vacuum bal-

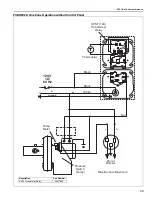

ance. Vacuum can be measured by inserting a

manometer hose into the end vent as shown

on

Page 50, Figure 35

. Normal end vent vacuum

should be set at approximately 2.5'' w.c. to 3.0''

w.c. (hot).

Vacuum adjustments are made by means of the

damper in the pump inlet and the adjustable

damper coupling(s) in the system. Check the

vacuum at all end vents and then adjust the

damper coupling to obtain equal vacuum

readings of 2.5'' w.c. to 3.0'' w.c. If end vent

vacuum exceeds 3.0" w.c., adjust the pump inlet

damper until vacuum readings are 2.5'' w.c. to

3.0'' w.c.

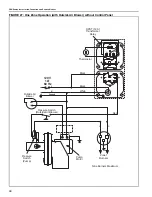

With systems designed to operate at maximum

vacuum, it may not be possible to obtain

vacuum differential readings at or slightly above

2.5'' w.c. If so, adjust the damper couplings to

maximum but equal vacuum reading. Be sure to

lock all dampers securely after adjustment.

3. Reset temperature setpoints to desired room

temperature.

4. If heat is not required, turn off main switch and

close the main gas valve.