ROBERTS GORDON

®

CORAYVAC

®

M

ODULATING

H

EATING

C

ONTROL

C

ONTROLLER

I

NSTALLATION

M

ANUAL

16

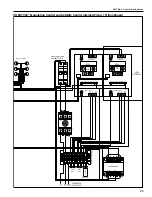

panel over pre-drilled holes and secure control panel

using minimum 5/16" - 18 x 2" bolts and washers (not

supplied).

3.3 Cable Requirements:

As per individual building specification for class of

cable to be used. Use copper conductors only. Below

is the recommended cable for the various connec-

tions for CORAYVAC

®

and COMPLETE™ Modulat-

ing Heating Control.

CAUTION:

• Separate line and low voltage circuits.

• Do not run line voltage wiring through bottom

section of enclosure that houses control

board.

• Do not run low voltage through top section of

enclosure that houses the relay board.

• Do not run line and low voltage wiring in same

conduit.

• Do not run wiring for vacuum pumps 1 and 2

from VFDs in the same conduit.

Note:

Avoid running communication wires or sensor input

wires next to AC power wires or the controller's relay

output wires. The resulting noise can affect signal

quality. Common sources of noise are:

• Spark igniters

• Radio transmitters

• Variable speed drives

• Electric motors (> 1hp)

• Generators

• Relays

• Transformers

• Induction heaters

• Large contactors (i.e., motor starters)

• Video display devices

• Lamp dimmers

• Fluorescent lights

3.4 CORAYVAC

®

and COMPLETE™ Modulating

Heating Control Installation Materials

Note:

Systems must be electrically grounded in

accordance with the following codes: United States:

Refer to National Electrical Code®, NFPA 70 - latest

revision. Wiring must conform to the most current

National Electrical Code®, local ordinances and any

special diagrams furnished.

Canada: Refer to Canadian Electrical Code, CSA

C22.1 Part 1 - latest revision. Plan accordingly.

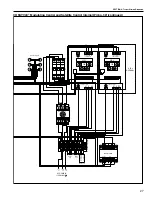

3.4.1 Switchable Loads

The controller relays are rated for switching loads no

greater than 6 A. The total added current load for all

4 relays must not exceed 20 A.

3.4.2 Control Programming Details

Controllers are pre-programmed. Can be configured

in the field to any combination of one/two pumps,

four heating zones, single stage or modulating uni-

tary heaters, CORAYVAC

®

or VANTAGE

®

Multiburner

systems.

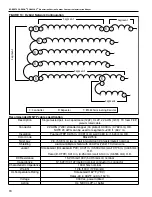

• Control Power Supply Connection

The power connection should be made with cable,

size 12 AWG.

• Four Digital Output (Relays)

The control connection for load of each individual

relay should be made with cable, size 14 AWG.

• Modulation Signal from Control Board (UO 5-8)

0-10V control signal from outputs UO 5-8 on the

modulation controller to modulating heaters, should

be made with cable, size 18 AWG.

• Digital Input

The wiring connection for the pressure switch should

be unshielded cable, size 18 AWG.

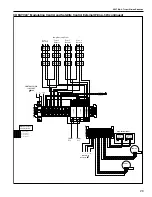

• Indoor Sensor Cable

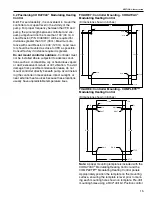

Rnet communication wires should be connected in a

daisy-chain or hybrid configuration. For star configu-

ration, contact factory. See examples

.

Note:

Use the specified type of wire and cable for

maximum signal integrity.

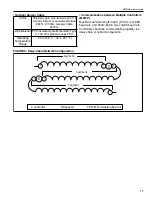

Description

4 conductor, shielded, CMP, plenum

rated cable

Conductor

22 AWG (7x0096) bare copper

Max Length

500’ (152 m)

Insulation

Low-smoke PVC (or equivalent)

Color Code

Black, white, green, red

Shielding

If shielded, Aluminum/Mylar shield

(100% coverage) with TC drain

wire

UL Temperature

Rating

32-167°F (0-75°C)

Voltage

300 Vac, power limited

Listing

UL: NEC CL2P, or better

Summary of Contents for CORAYVAC

Page 2: ......

Page 4: ......

Page 69: ...SECTION 8 PROGRAMMING AND TROUBLESHOOTING THE SYSTEM 65 THIS PAGE LEFT INTENTIONALLY BLANK ...

Page 71: ...SECTION 9 TROUBLESHOOTING 67 FIGURE 26 Vacuum pump does not turn on ...

Page 75: ...SECTION 9 TROUBLESHOOTING 71 FIGURE 31 Burner troubleshooting in manual mode ...

Page 77: ...SECTION 9 TROUBLESHOOTING 73 After 45 second prepurge burners do not light continued ...

Page 81: ...SECTION 9 TROUBLESHOOTING 77 FIGURE 36 Air Pressure Switch alarm ...

Page 83: ...SECTION 9 TROUBLESHOOTING 79 FIGURE 38 Repeater troubleshooting ...

Page 85: ...SECTION 9 TROUBLESHOOTING 81 BACnet MS TP troubleshooting continued ...

Page 109: ...SECTION 13 TOUCHSCREEN TREE 105 Touchscreen Tree Overview continued ...

Page 111: ...SECTION 13 TOUCHSCREEN TREE 107 FIGURE 47 Maintenance Unit FIGURE 48 Alarms ...

Page 113: ...SECTION 13 TOUCHSCREEN TREE 109 FIGURE 51 Configuration Zones FIGURE 52 Configuration Unit ...

Page 115: ...SECTION 13 TOUCHSCREEN TREE 111 FIGURE 55 Touchscreen System FIGURE 56 Touchscreen Setup ...

Page 118: ...ROBERTS GORDON CORAYVAC MODULATING HEATING CONTROL CONTROLLER INSTALLATION MANUAL 114 ...