ROBERTS GORDON

®

CORAYVAC

®

M

ODULATING

H

EATING

C

ONTROL

C

ONTROLLER

I

NSTALLATION

M

ANUAL

40

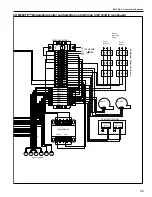

wire, MS/TP loop which connects multiple ROBERTS

GORDON

®

controllers. A BACnet/IP connection is

also possible. For jobs which require an integration

with another BMS,

object points list is required to integrate to the

CORAYVAC

®

Modulating Heating Control into an

existing BMS system to allow for read/write access.

Contact Roberts-Gordon or your local ROBERTS

GORDON

®

independent distributor for the list of

object points. A foreign BMS will have the ability to

control occupancy, setpoints and more. I/O Pro 812U

has ability to speak to one of the following protocols:

• BACnet over ARC156

• BACnet MS/TP

• BACnet PTP

• BACnet over IP

• BACnet over Ethernet

• Modbus

• N2

• LonWorks

• Refer to

Contact Roberts-Gordon LLC or your independent

ROBERTS GORDON

®

distributor for more details.

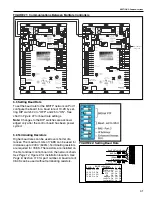

5.4 Communications Between Multiple

CORAYVAC

®

Modulating Heating Controls

If more than one CORAYVAC

®

Modulating Heating

Control is installed in a building, the controllers' MS/

TP communications must be wired in series.

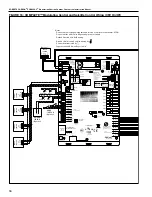

. Connect the MS/TP (Port 1) ter-

minal on controller #1 to the MS/TP (Port 1) terminal

on controller #2 and so on in a daisy chain (

) fashion. Shield wires for MS/TP cables

should be twisted together, but not grounded, at all

satellite controllers in daisy chain. Ground shield wire

at central panel only.

Maximum of 31 controllers to 1 central controller. For

communication cable requirements,

. A MAC address is required for each

central and satellite controller using the "Rotary

Switches"

. There are 2 rotary

switches.

The upper rotary switch is labeled "1's" and lower

rotary switch is labeled "10's". To set the MAC

address for the first 9 controllers, the lower rotary

switch (10's) is set to "0", the upper rotary switch (1's)

is set to the appropriate controller number. To set the

MAC address for controller numbers 10 and up, the

setting of the lower rotary switch (10's) must be com-

bined with the value of the upper rotary switch (1's).

For example: To set the MAC address to "10", adjust

the lower rotary switch (10's) to "1" and adjust the

upper rotary switch (1's) to "0".

Note:

All central controllers should be set to "1". All

controllers should have a unique number assigned

using the rotary switch dials. Changes to the rotary

switches are acknowledged only after the board has

been power cycled.

Contact Roberts-Gordon LLC or your ROBERTS

GORDON

®

independent distributor, if more than 31

controllers are required.

Summary of Contents for CORAYVAC

Page 2: ......

Page 4: ......

Page 69: ...SECTION 8 PROGRAMMING AND TROUBLESHOOTING THE SYSTEM 65 THIS PAGE LEFT INTENTIONALLY BLANK ...

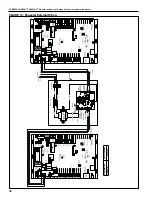

Page 71: ...SECTION 9 TROUBLESHOOTING 67 FIGURE 26 Vacuum pump does not turn on ...

Page 75: ...SECTION 9 TROUBLESHOOTING 71 FIGURE 31 Burner troubleshooting in manual mode ...

Page 77: ...SECTION 9 TROUBLESHOOTING 73 After 45 second prepurge burners do not light continued ...

Page 81: ...SECTION 9 TROUBLESHOOTING 77 FIGURE 36 Air Pressure Switch alarm ...

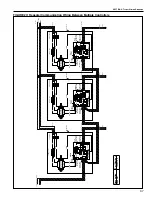

Page 83: ...SECTION 9 TROUBLESHOOTING 79 FIGURE 38 Repeater troubleshooting ...

Page 85: ...SECTION 9 TROUBLESHOOTING 81 BACnet MS TP troubleshooting continued ...

Page 109: ...SECTION 13 TOUCHSCREEN TREE 105 Touchscreen Tree Overview continued ...

Page 111: ...SECTION 13 TOUCHSCREEN TREE 107 FIGURE 47 Maintenance Unit FIGURE 48 Alarms ...

Page 113: ...SECTION 13 TOUCHSCREEN TREE 109 FIGURE 51 Configuration Zones FIGURE 52 Configuration Unit ...

Page 115: ...SECTION 13 TOUCHSCREEN TREE 111 FIGURE 55 Touchscreen System FIGURE 56 Touchscreen Setup ...

Page 118: ...ROBERTS GORDON CORAYVAC MODULATING HEATING CONTROL CONTROLLER INSTALLATION MANUAL 114 ...