ROBERTS GORDON

®

CORAYVAC

®

M

ODULATING

H

EATING

C

ONTROL

C

ONTROLLER

I

NSTALLATION

M

ANUAL

50

6.2.1 Acknowledge error message (Reset)

To acknowledge and reset the current error mes-

sage, you can either switch off the supply voltage or

press the STOP button. Error messages (a maximum

of four) are stored in parameter P-13.

6.2.2 Error Messages

The following table shows the Error messages list,

the possible causes and indicates corrective mea-

sures. Refer to the supplied VFD installation and

operation manual for more details or VFD trouble-

shooting.

Failure

Code

[hex]

View

Designation

Possible Cause

Notes

01

01-b

Braking chopper over

current

• Overcurrent braking

resistance

• Overcurrent in braking resistor

circuit.

• Check the wiring to the braking

resistance.

• Check the brake resistor value.

Make sure to adhere to mini-

mum resistance values.

02

0L-br

Thermal overload braking

resistance

• Braking resistance

overload

• Increase the deceleration time,

reduce the load's moment of

inertia, or connect additional

braking resistors in parallel.

• Make sure to adhere to mini-

mum resistance values.

03

0-I

Overcurrent motor

• Overcurrent at output

• Motor overload

• Overtemperature at

heat sink

• Short circuit / ground

fault

• Motor with constant speed:

Determine the overload or fault.

• Motor starts: The load stalled or

has seized. Check whether

there is a star/delta motor wir-

ing error.

• Motor accelerates/decelerates:

The excessively short accelera-

tion/deceleration time is requir-

ing too much power. If P-03 or

P-04 cannot be increased, a

more powerful variable fre-

quency drive is required.

• Cable fault between variable

frequency drive and motor.

04

It-trF

Thermal motor overload

• The DC1 variable fre-

quency drive was

switched off after

more than 100% of

the value set in P-08

was delivered for a

period of time

• Check whether the decimal

places are flashing (variable

frequency drive overloaded)

and either raise the accelera-

tion ramp (P-03) or reduce the

motor load.

• Make sure that the cable length

matches the variable fre-

quency drive specifications.

• Check the load mechanically in

order to make sure that it is

free, that nothing is getting

jammed or locked, and there

are no other mechanical faults.

Summary of Contents for CORAYVAC

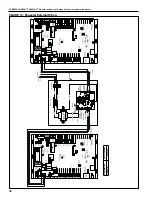

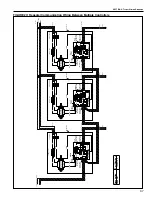

Page 2: ......

Page 4: ......

Page 69: ...SECTION 8 PROGRAMMING AND TROUBLESHOOTING THE SYSTEM 65 THIS PAGE LEFT INTENTIONALLY BLANK ...

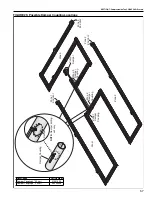

Page 71: ...SECTION 9 TROUBLESHOOTING 67 FIGURE 26 Vacuum pump does not turn on ...

Page 75: ...SECTION 9 TROUBLESHOOTING 71 FIGURE 31 Burner troubleshooting in manual mode ...

Page 77: ...SECTION 9 TROUBLESHOOTING 73 After 45 second prepurge burners do not light continued ...

Page 81: ...SECTION 9 TROUBLESHOOTING 77 FIGURE 36 Air Pressure Switch alarm ...

Page 83: ...SECTION 9 TROUBLESHOOTING 79 FIGURE 38 Repeater troubleshooting ...

Page 85: ...SECTION 9 TROUBLESHOOTING 81 BACnet MS TP troubleshooting continued ...

Page 109: ...SECTION 13 TOUCHSCREEN TREE 105 Touchscreen Tree Overview continued ...

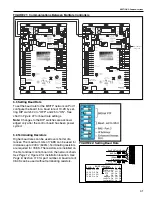

Page 111: ...SECTION 13 TOUCHSCREEN TREE 107 FIGURE 47 Maintenance Unit FIGURE 48 Alarms ...

Page 113: ...SECTION 13 TOUCHSCREEN TREE 109 FIGURE 51 Configuration Zones FIGURE 52 Configuration Unit ...

Page 115: ...SECTION 13 TOUCHSCREEN TREE 111 FIGURE 55 Touchscreen System FIGURE 56 Touchscreen Setup ...

Page 118: ...ROBERTS GORDON CORAYVAC MODULATING HEATING CONTROL CONTROLLER INSTALLATION MANUAL 114 ...