SECTION 12: I

NTEGRATION WITH

B

UILDING

M

ANAGEMENT

S

YSTEM

(BMS)

93

• If RX LED is solid, then the terminations are incor-

rect.

• If the network has greater than 32 devices or

exceeds 2000’ (610 m) a Repeater should be

installed.

• If a controller begins or ends a network segment,

a terminating resistor may be needed.

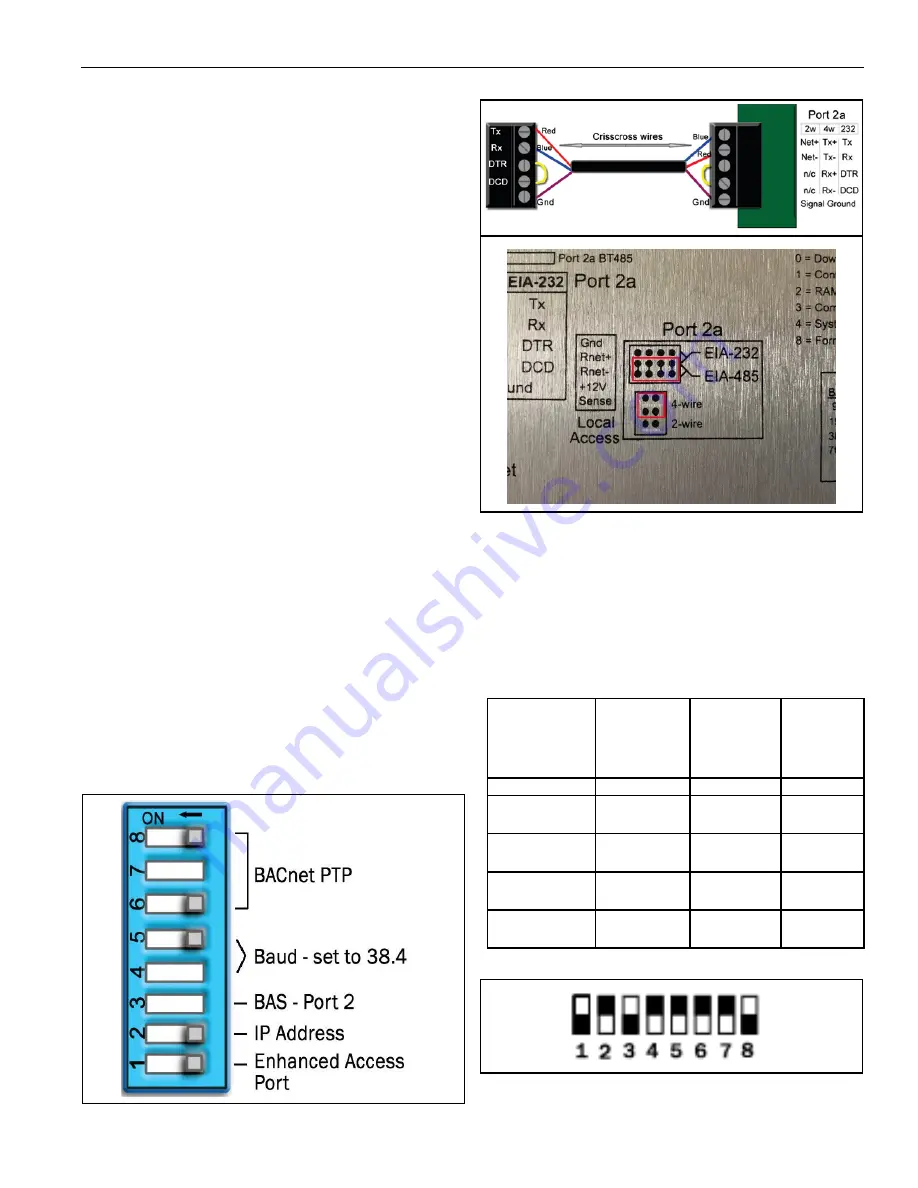

12.3 BACnet PTP

PTP is used to connect 2 distinct BACnet networks

so that information can be shared between the

networks. PTP uses an EIA-232 connection between

2 BACnet half-routers. This connection allows for 2

different BACnet networks to speak to each other,

even at different baud rates.

To set up the Modulating Controller for BACnet

PTP

1. Turn off power to control board.

2. Using the rotary switches, set the controller's

address. Set the Tens (10's) switch to the tens digit

of the address and set the Ones (1's) switch to the

ones digit.

3. Set the Selector DIP Switches 4 and 5 for the

appropriate communications speed (9600, 19.2k,

38.4k, or 76.8k bps).

4. Set Comm Selector DIP Switch 3 to ON for Port 2.

Note:

Comm Selector DIP Switch 4 (Port 1) will be

set by the manufacturer.

5. Set the DIP Switch Selector 6-8 for BACnet PTP.

The following example shows the DIP Switches set

for 38.4k, Port 2, and BACnet PTP.

6. Connect the communications wiring to Port 2a.

Wire Specifications

•

18–28 AWG; twisted pair preferable

• 50’ (15.24 m) maximum length

Note:

Do not power the device from the same

transformer that powers controller.

7. S

ee table below to wire control board to a modem.

8. Set the following DIP switch on the modem.

Note:

US Robotics External Modem is highly

recommended.

Modem (25-

pin)

Null Modem

Cable

Null

Modem

Cable

(9-pin)

S2-DB9

(9-pin)

Device

(5 pin)

TX - pin 2

TX - pin 3

TX - pin 3

TX - pin 1

RX - pin 3

RX - pin 2

RX - pin 2

RX - pin

2

DTR - pin 20

DTR - pin

4

DTR - pin

4

DTR - pin

3

DCD - pin 8

DCD - pin

1

DCD - pin

1

DCD -

pin 4

GND - pin 7

GND - pin

5

GND - pin

5

GND -

pin 5

Summary of Contents for CORAYVAC

Page 2: ......

Page 4: ......

Page 69: ...SECTION 8 PROGRAMMING AND TROUBLESHOOTING THE SYSTEM 65 THIS PAGE LEFT INTENTIONALLY BLANK ...

Page 71: ...SECTION 9 TROUBLESHOOTING 67 FIGURE 26 Vacuum pump does not turn on ...

Page 75: ...SECTION 9 TROUBLESHOOTING 71 FIGURE 31 Burner troubleshooting in manual mode ...

Page 77: ...SECTION 9 TROUBLESHOOTING 73 After 45 second prepurge burners do not light continued ...

Page 81: ...SECTION 9 TROUBLESHOOTING 77 FIGURE 36 Air Pressure Switch alarm ...

Page 83: ...SECTION 9 TROUBLESHOOTING 79 FIGURE 38 Repeater troubleshooting ...

Page 85: ...SECTION 9 TROUBLESHOOTING 81 BACnet MS TP troubleshooting continued ...

Page 109: ...SECTION 13 TOUCHSCREEN TREE 105 Touchscreen Tree Overview continued ...

Page 111: ...SECTION 13 TOUCHSCREEN TREE 107 FIGURE 47 Maintenance Unit FIGURE 48 Alarms ...

Page 113: ...SECTION 13 TOUCHSCREEN TREE 109 FIGURE 51 Configuration Zones FIGURE 52 Configuration Unit ...

Page 115: ...SECTION 13 TOUCHSCREEN TREE 111 FIGURE 55 Touchscreen System FIGURE 56 Touchscreen Setup ...

Page 118: ...ROBERTS GORDON CORAYVAC MODULATING HEATING CONTROL CONTROLLER INSTALLATION MANUAL 114 ...